Automatic weighing machines are critical in industries for ensuring precise weight measurements. These machines come in various types and options, each catering to specific use cases such as high-speed processing, batch weighing, or multi-component weighing.

– Single-Head Weighers: Suitable for simple, single product applications; often used in food production.

– Multi-Head Weighers: Ideal for high-speed operations involving multiple components or products; common in snack packaging.

– Checkweighers: Ensure products meet specified weight criteria; used for quality control.

– Bulk Weighers: Designed for weighing large quantities of materials, often used in agriculture or mining.

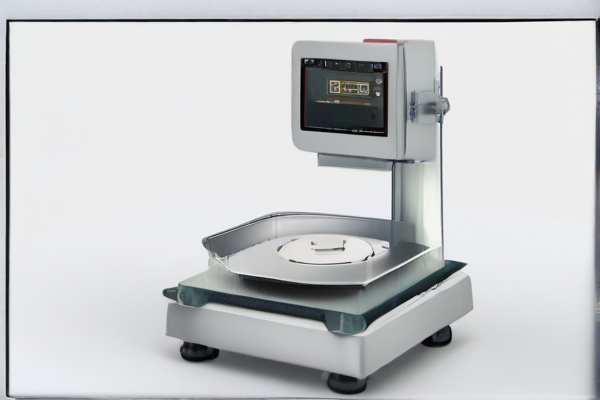

– Bench Scales: Versatile and suitable for a range of applications including postal services and retail environments.

– Conveyor Scales: Integrated into conveyor systems for continuous, dynamic weighing in manufacturing processes.

– Precision Balances: Used in laboratory and scientific settings for highly accurate measurements.

– Platform Scales: Suitable for large, heavy items in industrial settings, such as logistics and shipping.

– Smart Weighing Systems: Equipped with advanced technologies like IoT connectivity, data logging, and remote monitoring.

Options available:

– Load Capacity: Varies from small grams to several tons depending on the application.

– Accuracy Level: Precision can vary from high accuracy (0.01 grams) to general accuracy (1 kg).

– Material Construction: Stainless steel, aluminum, or composite materials depending on the environment.

– Display Types: Digital, analog, or remote displays to suit different needs.

– Automated Controls: Can include programmable settings, automated sorting, rejection mechanisms, and integration with other systems.

– Power Source: Options include battery-powered, mains electric, or renewable energy sources like solar.

– Connectivity: Features like USB, Bluetooth, Wi-Fi, and Ethernet for data transfer and system integration.

– Environmental Resistance: Options for water-resistant, dust-proof, and explosion-proof designs.

– Compliance: Machines adhering to industry standards and certifications for safety and reliability.

Choosing the right automatic weighing machine depends on the operational requirements, budget, and specific industrial applications. Careful consideration of the type and features ensures optimal performance and efficiency.