Sure, here’s a list of frequently asked questions (FAQ) with answers, specifically for manufacturing auxiliary machine quality work from SourcifyChina factory. Each question is marked with a `` tag:

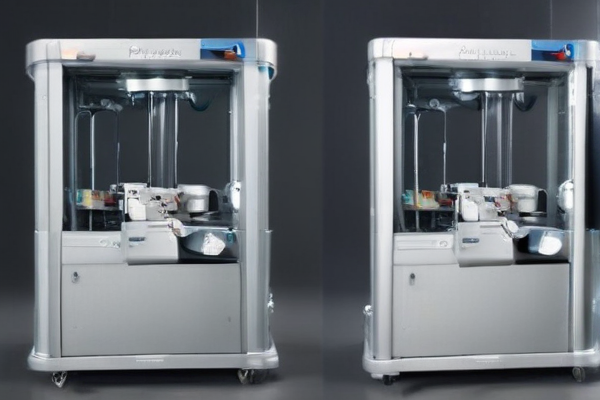

1. What auxiliary machines do you manufacture?

We manufacture a wide range of auxiliary machines, including conveyors, feeders, mixers, grinders, and custom-engineered devices tailored to specific industrial processes.

2. How do you ensure the quality of your auxiliary machines?

We follow strict quality control procedures which include material inspection, production monitoring, and final testing before delivery. We also comply with international standards such as ISO and CE certifications.

3. Can you customize auxiliary machines to meet specific requirements?

Yes, we offer customized solutions based on your unique needs. Our engineering team works closely with clients to design and produce machines that meet precise specifications.

4. What materials are used in the construction of your auxiliary machines?

We use high-quality materials such as stainless steel, carbon steel, and high-grade alloys to ensure durability and longevity under various industrial conditions.

5. How long does it take to manufacture an auxiliary machine?

The manufacturing lead time typically ranges from 4 to 8 weeks, depending on the complexity and customization required for the machine.

6. Do you provide installation and after-sales support?

Yes, we offer comprehensive installation services and after-sales support, including training, troubleshooting, and maintenance to ensure smooth operation.

7. What is the warranty period for your auxiliary machines?

Our auxiliary machines come with a standard one-year warranty, which covers parts and labor. Extended warranties can be arranged upon request.

8. Can you handle bulk orders?

Absolutely, we have the capacity to handle bulk orders and maintain consistent quality and timely delivery.

9. How do I place an order?

You can place an order by contacting our sales team via email or phone. We will guide you through the process, including providing quotations and confirming specifications.

10. What are the payment terms?

We typically require a 30% deposit upfront, with the remaining balance due before shipment. We accept various payment methods, including bank transfers and letters of credit.