FAQs for Manufacturing “Bag and Seal Machine Quality Work from SourcifyChina Factory”

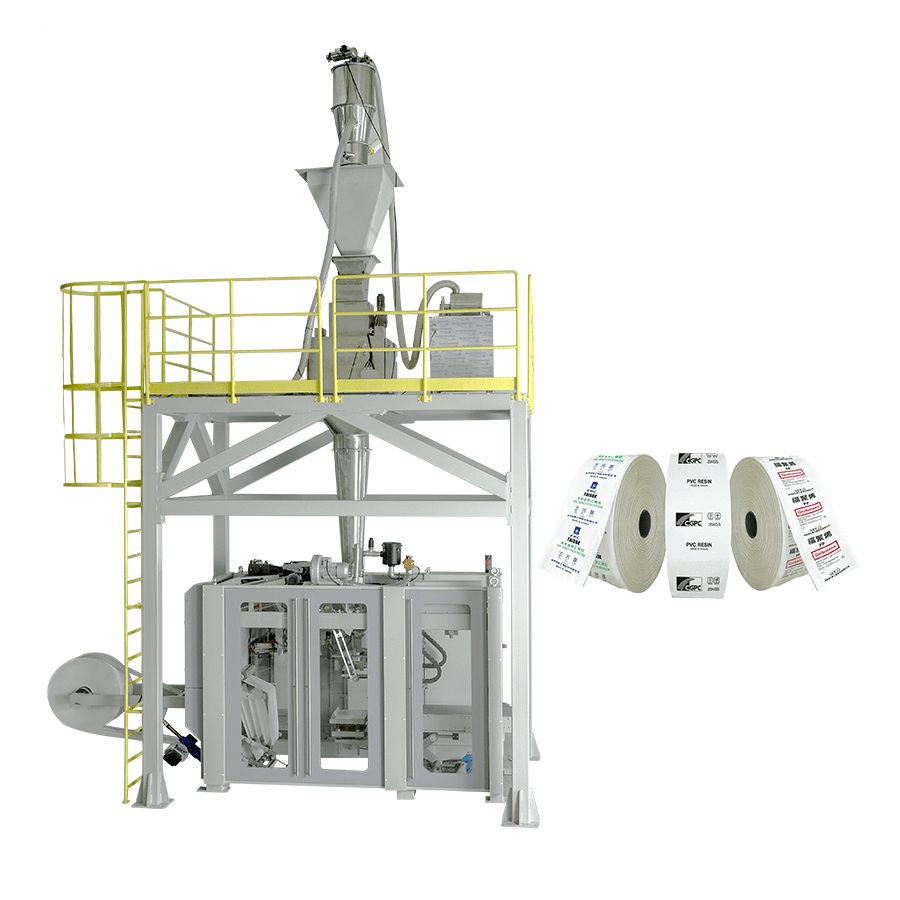

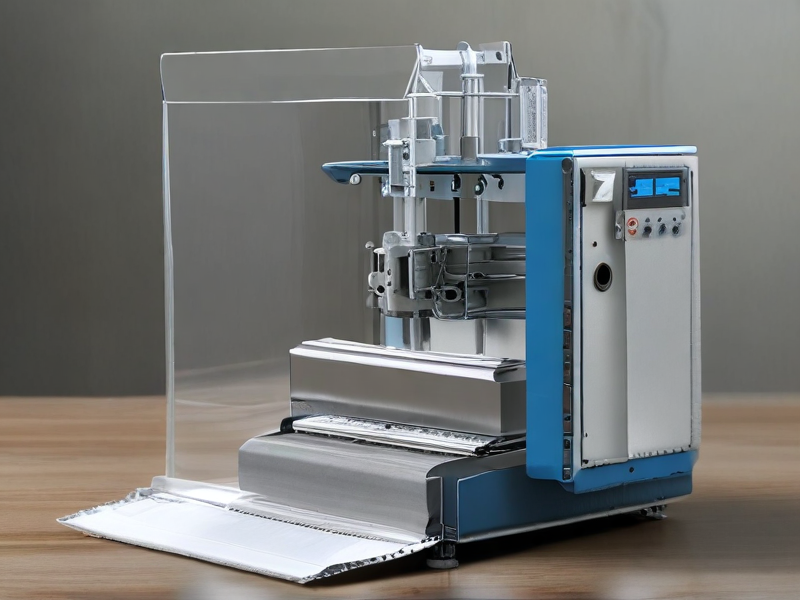

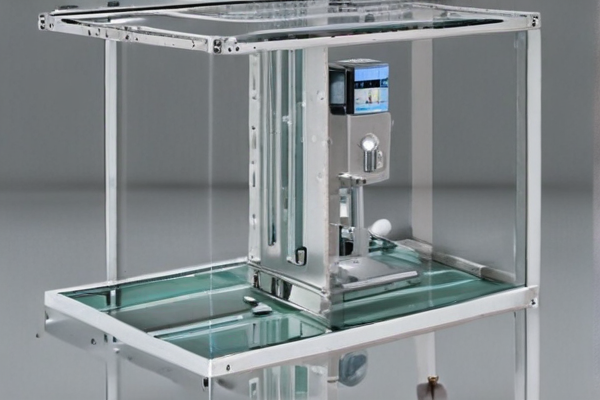

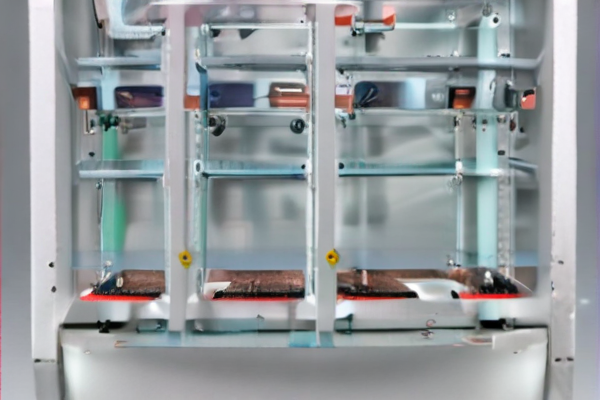

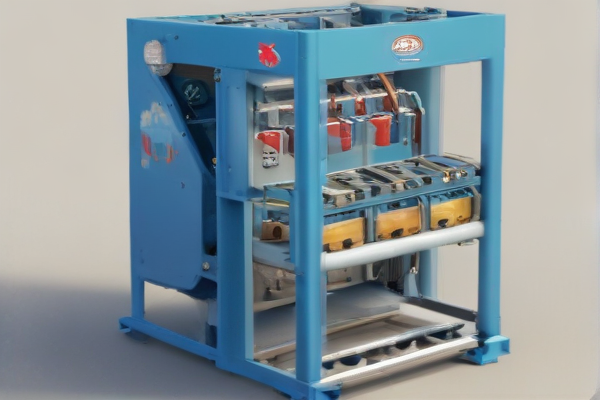

Q: What types of bag and seal machines does SourcifyChina factory produce?

A: SourcifyChina specializes in a wide range of bag and seal machines, including vertical and horizontal form-fill-seal (FFS) machines, pre-made pouch packing machines, vacuum sealers, and automated bagging machines.

Q: What materials are compatible with SourcifyChina’s bag and seal machines?

A: Our machines are compatible with various materials such as polyethylene, polypropylene, laminates, aluminum foil, and other composite films.

Q: How do you ensure the quality of the machines?

A: Quality assurance at SourcifyChina includes rigorous testing, adherence to international standards, and continuous monitoring during the manufacturing process. We also provide certifications and inspection reports upon request.

Q: What is the lead time for manufacturing and delivery?

A: The lead time depends on the complexity and customization of the machine, but typically ranges from 6 to 12 weeks.

Q: Do you offer customization options for specific needs?

A: Yes, SourcifyChina provides customization options based on client specifications. We work closely with clients to design and manufacture machines that meet their unique requirements.

Q: What is the warranty period for your machines?

A: Our machines come with a standard one-year warranty. Extended warranties and maintenance packages are also available.

Q: Can you provide installation and training services?

A: Absolutely, we offer comprehensive installation and training services to ensure your team can operate the machines efficiently and effectively.

Q: Are spare parts readily available?

A: Yes, we stock a wide range of spare parts for all our machines to ensure timely replacements and minimal downtime.

Q: How can I receive technical support after purchase?

A: Technical support is available through multiple channels including email, phone, and live video assistance. Our dedicated support team is available 24/7 to assist with any issues.

Q: Do you have references or case studies from previous customers?

A: Yes, we can provide references and case studies showcasing our successful projects and satisfied clients. Please contact us for more information.

Q: How do you handle international shipping and customs?

A: SourcifyChina handles all aspects of international shipping and customs clearance. We ensure timely delivery and compliance with regulations in your country.