Sure, here’s an FAQ for sourcing bag filling equipment from SourcifyChina factory:

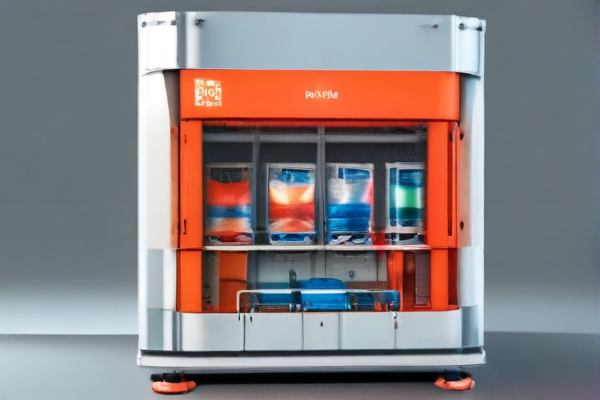

What types of bag filling equipment does SourcifyChina factory offer?

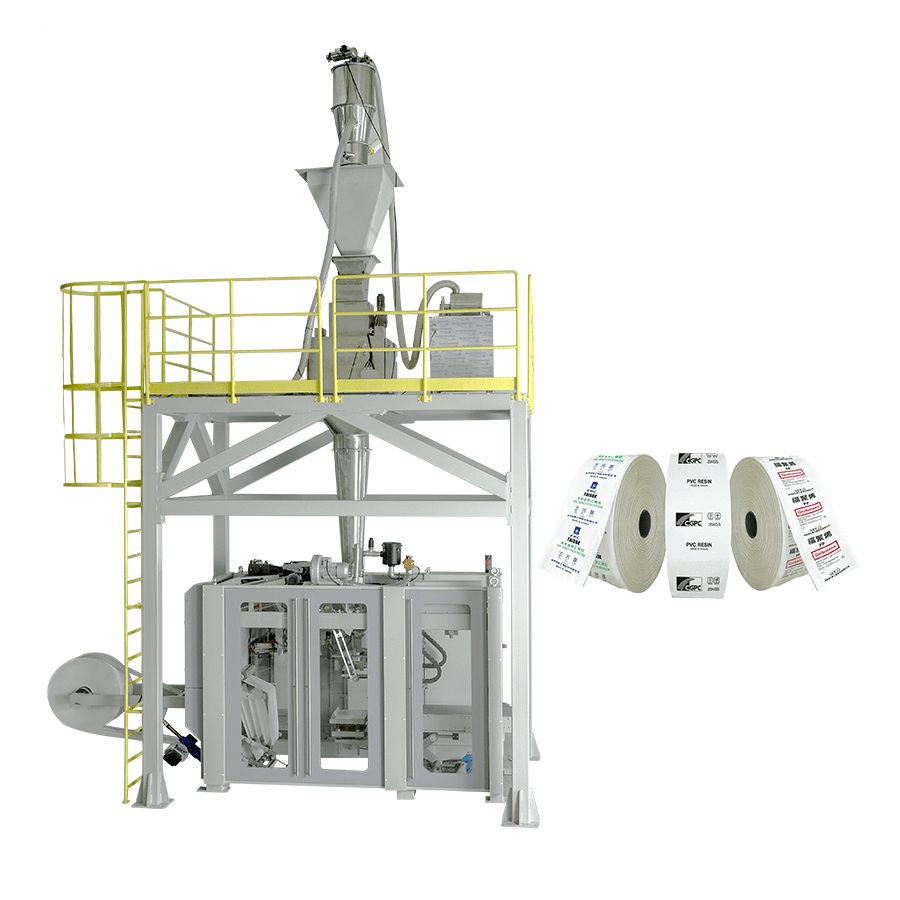

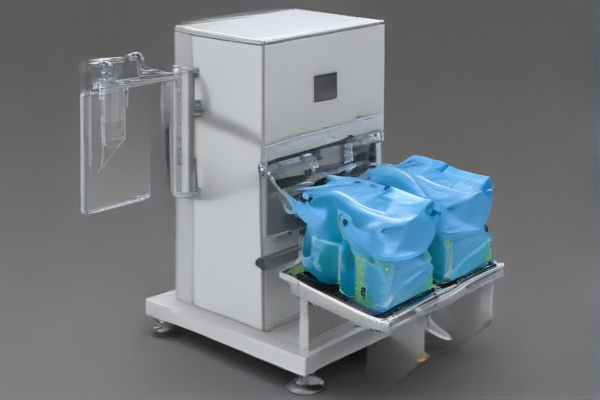

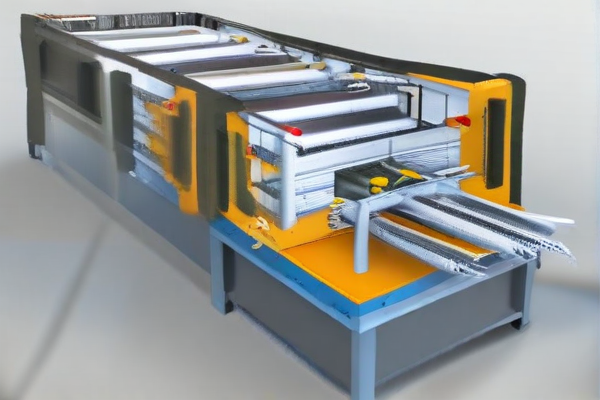

SourcifyChina provides a range of bag filling equipment, including automatic, semi-automatic, and manual machines. These machines can handle different materials such as powders, granules, and liquids.

Can I customize the bag filling equipment to suit my specific needs?

Yes, SourcifyChina offers customization services to tailor the equipment according to your technical specifications and operational requirements.

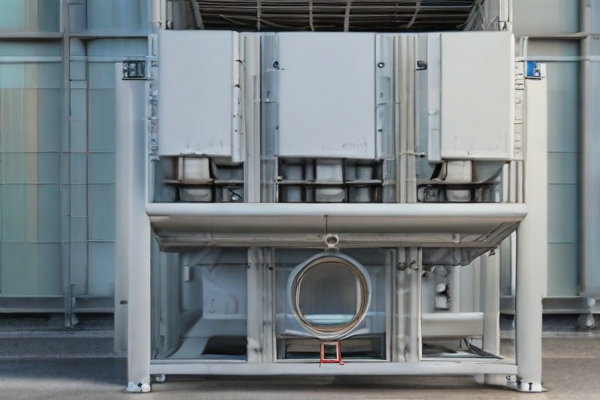

What materials are the bag filling machines built from?

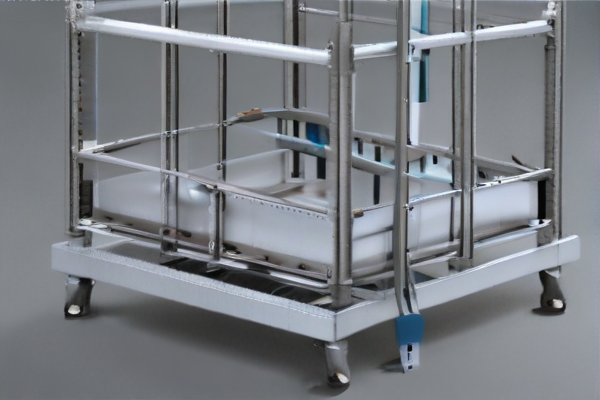

The machines are constructed using high-quality stainless steel and other durable materials to ensure longevity and efficiency.

What is the lead time for manufacturing and delivering the equipment?

The typical lead time ranges from 4 to 12 weeks, depending on the complexity and customization requirements of the order.

Is there a minimum order quantity (MOQ) for purchasing the equipment?

SourcifyChina generally requires a minimum order, but it can vary based on the specific product and customization needs. It’s best to consult directly for precise details.

Do you provide after-sales support and maintenance services?

Yes, SourcifyChina offers comprehensive after-sales support, including installation assistance, maintenance services, and training for operators.

Can I visit the factory to inspect the equipment before purchase?

Absolutely, factory visits are welcomed. You can schedule a visit to inspect the manufacturing process and the quality of the equipment firsthand.

Are there any certifications available for your bag filling equipment?

SourcifyChina’s equipment complies with international standards and certifications, such as ISO, CE, and GMP, ensuring high-quality and reliable performance.

How do I place an order for the bag filling equipment?

You can place an order by contacting SourcifyChina directly through their website or via email. A representative will guide you through the process, including customization options and payment terms.

What payment methods does SourcifyChina accept?

SourcifyChina typically accepts various payment methods, including wire transfers, L/C, and other conventional payment options. Specific terms can be discussed during the order process.