Sure, here are some frequently asked questions (FAQ) with answers about sourcing a bag filling machine from SourcifyChina Factory:

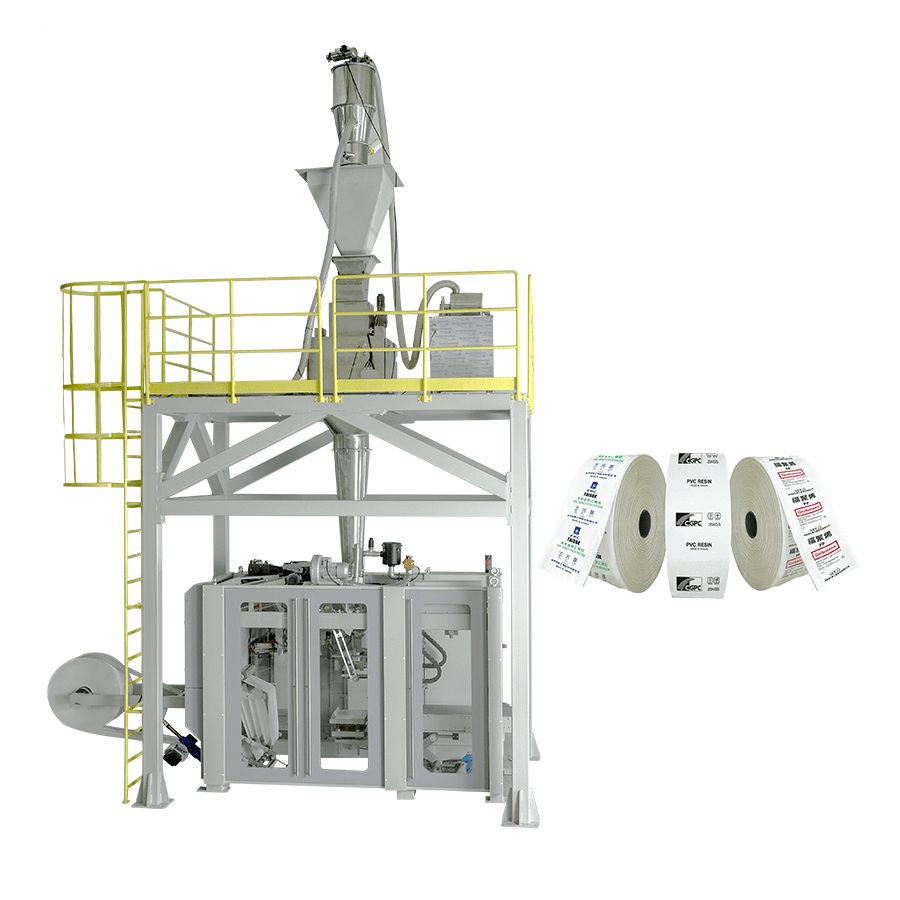

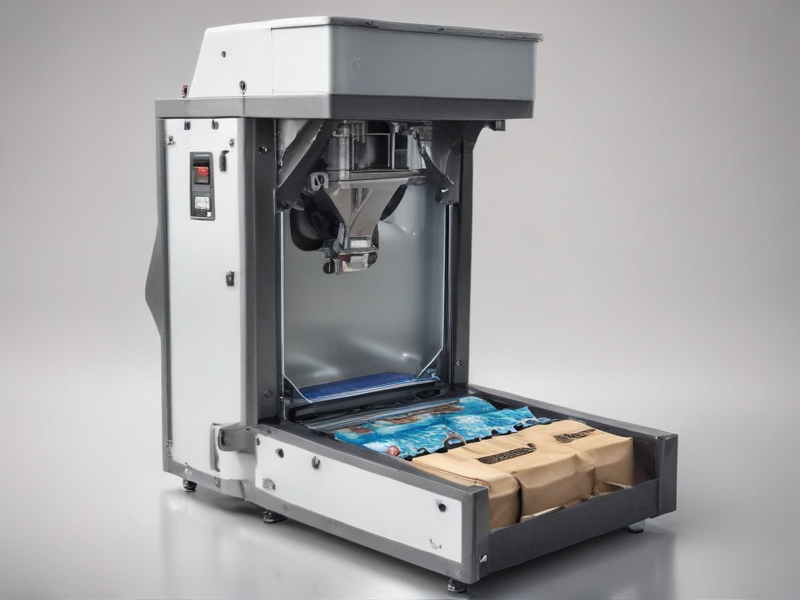

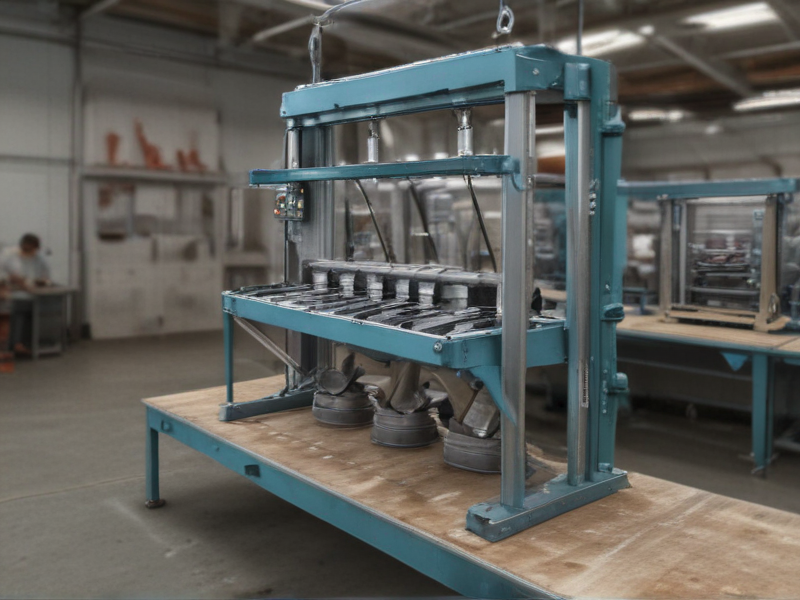

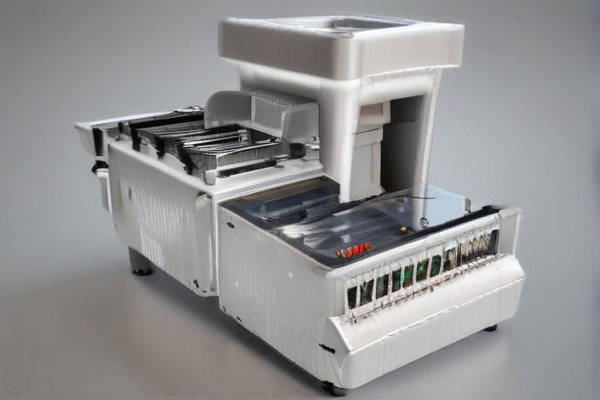

Q: What types of bag filling machines does SourcifyChina Factory offer?

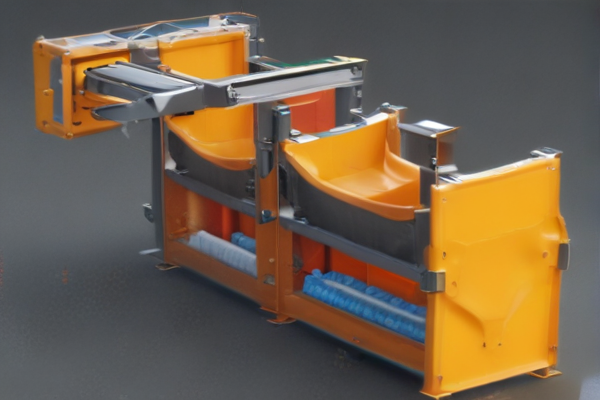

A: SourcifyChina Factory offers a variety of bag filling machines, including automatic, semi-automatic, and manual models designed for different materials such as powders, granules, and liquids.

Q: How can I request a quotation for a bag filling machine?

A: To request a quotation, visit SourcifyChina’s official website and fill out the inquiry form with your specific requirements, or directly contact their sales team via email or phone.

Q: What information should I provide for an accurate quote?

A: Provide details such as the type of material to be filled, desired filling speed, bag size, and any special features you need. The more specific you are, the more accurate the quote will be.

Q: What is the typical lead time for manufacturing and delivery?

A: The lead time varies depending on the machine’s complexity and customization. It generally ranges from 4 to 8 weeks for manufacturing, plus additional time for shipping, which depends on your location.

Q: Does SourcifyChina Factory provide installation and after-sales support?

A: Yes, they offer installation guidance, user manuals, and video tutorials. Additionally, they provide after-sales support, including maintenance services and spare parts.

Q: Can I visit the factory to inspect the machines?

A: Absolutely. SourcifyChina Factory welcomes customers to visit their facility. Contact their team to schedule a visit and see the machines in action.

Q: What are the payment terms?

A: Payment terms typically involve a deposit, with the balance due upon completion or before shipment. Specific terms can be negotiated based on the order size and customer relationship.

Q: Is there a warranty for the bag filling machines?

A: Yes, SourcifyChina Factory offers a standard warranty period, typically one year, which covers defects in materials and workmanship. Extended warranties may also be available.

Q: How is the quality of the machines ensured?

A: Quality is ensured through strict adherence to international manufacturing standards, rigorous testing, and quality control processes, along with certifications like ISO and CE.

Q: Can the machines be customized to my specific requirements?

A: Yes, SourcifyChina Factory offers customization to meet your specific needs, including modifications in design, capacity, and functionalities.