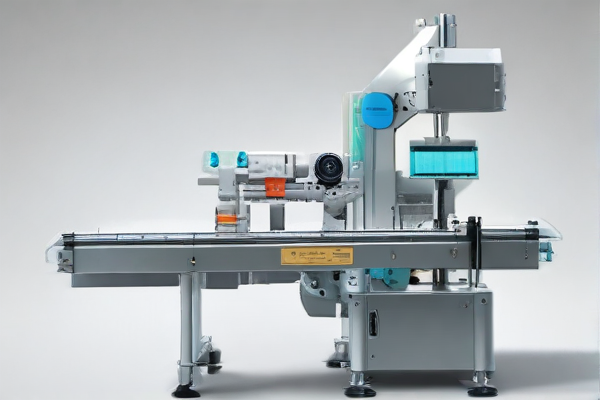

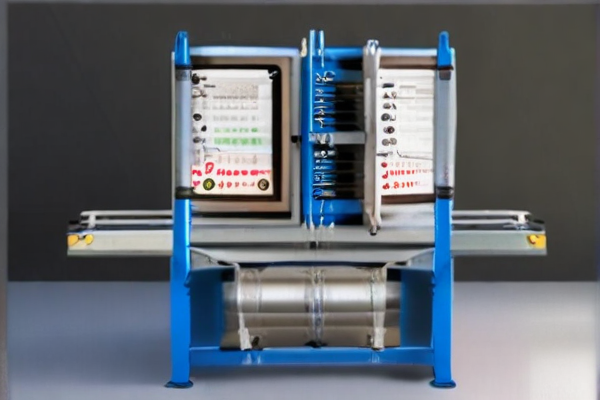

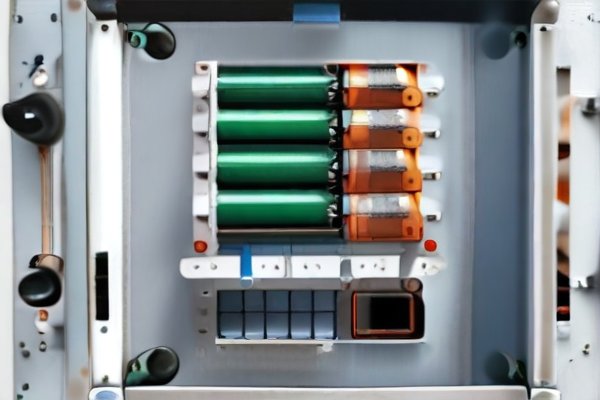

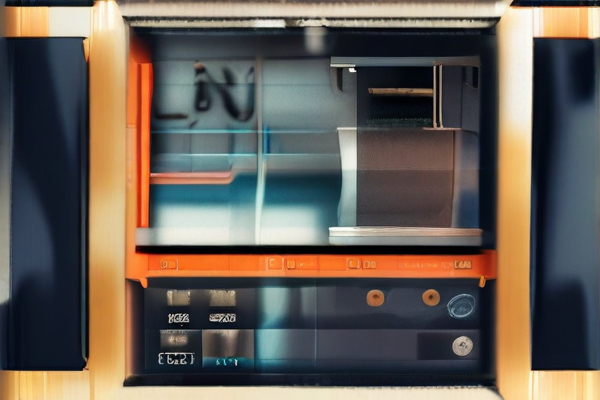

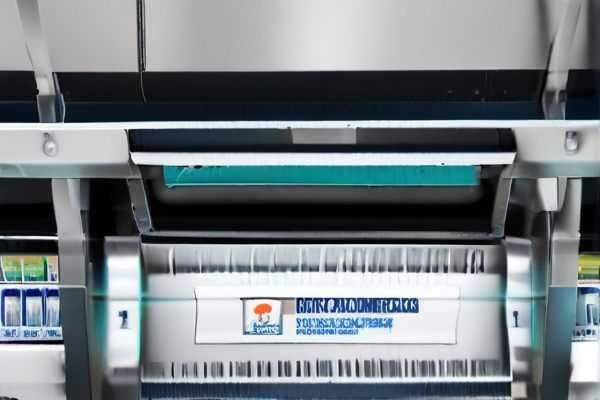

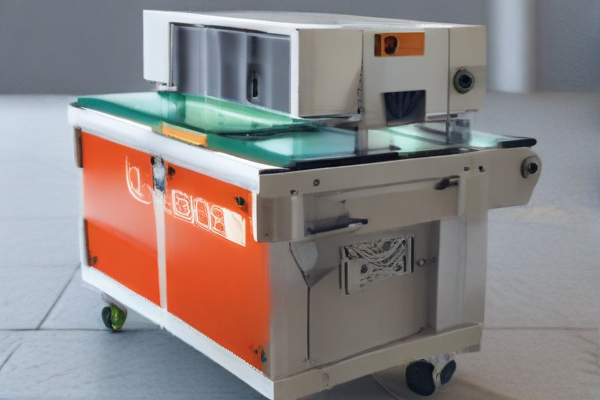

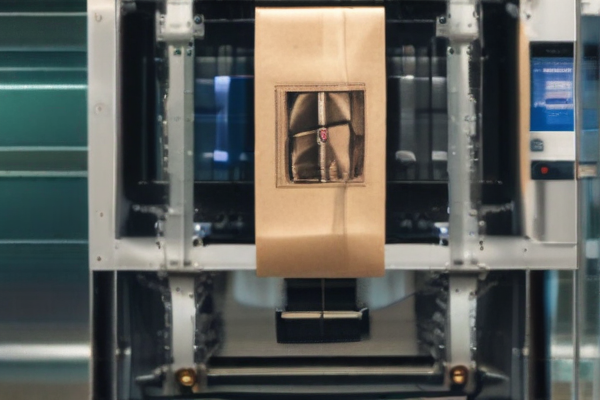

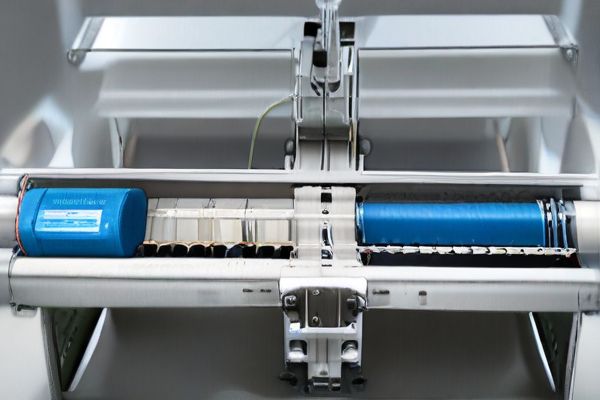

Bag labeling machines are essential in various industries for efficiently affixing labels on packaging bags, streamlining the labeling process, and ensuring consistency and accuracy.

– Food Industry: Labels nutritional information, expiration dates, and barcodes.

– Pharmaceuticals: Ensures precise labeling of dosage and regulatory information.

– Manufacturing: Applies product identification and batch numbers.

– Retail: Tags for inventory management and pricing.

– Agriculture: Labels seed packets, fertilizers, and other products.

– Logistics and Shipping: Affixes destination and tracking information.

– Cosmetics: Ensures proper labeling of ingredients and usage instructions.

– Automotive: Marks parts with serial numbers and manufacturing details.

– Electrical and Electronics: Provides safety information and specifications.

– Fashion and Textiles: Labels fabric materials and care instructions.

– Chemicals: Ensures hazardous materials are correctly labeled for safety.

– Tobacco: Compliance with regulatory labeling requirements.

– Pet Products: Identifies content and usage instructions.

– Household Products: Labels cleaners and detergents with safety information.

– Healthcare: Labels medical devices and supplies.

– Toys and Games: Ensures compliance with safety standards through proper labeling.

– Construction Materials: Tags materials with specifications and usage guidelines.

– Stationery: Labels books, pens, and office supplies for inventory.

– Seasonal Products: Specialized labeling for holiday and seasonal goods.

– Beverage Industry: Labels bottled water, juices, and other drinks with brand and nutritional info.

– Grocery Stores: Prepares packaging for bulk and fresh produce.

– Printing Services: For custom and variable data labeling.

– E-commerce: Handles dynamic labeling for various products sold online.

– Textiles and Apparel: Affixes size and brand labels on clothing items.

– Cannabis Industry: Compliance with labeling regulations for cannabis products.

– Custom Packaging: Facilitates unique and custom label designs.

– Electronics Retail: Affixes warranty and certification labels.

– Organic Products: Labels authenticity and certification of organic status.

Bag labeling machines highly benefit industries by improving efficiency, accuracy, and compliance.