Sure! Here is a concise FAQ list for manufacturing bag machines with quality work from SourcifyChina Factory:

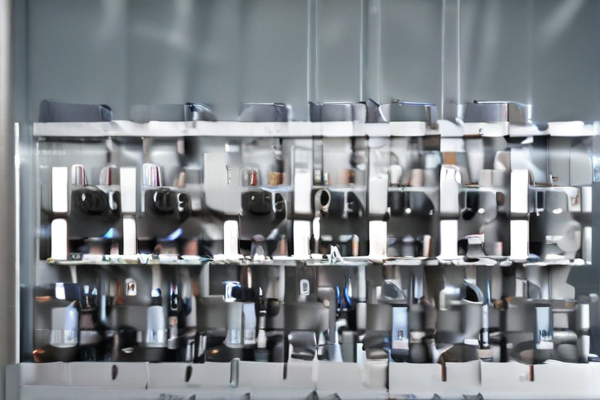

1. What types of bag machines does SourcifyChina manufacture?

SourcifyChina manufactures a wide range of bag machines, including automatic bag-making machines, non-woven bag machines, paper bag machines, and plastic bag machines.

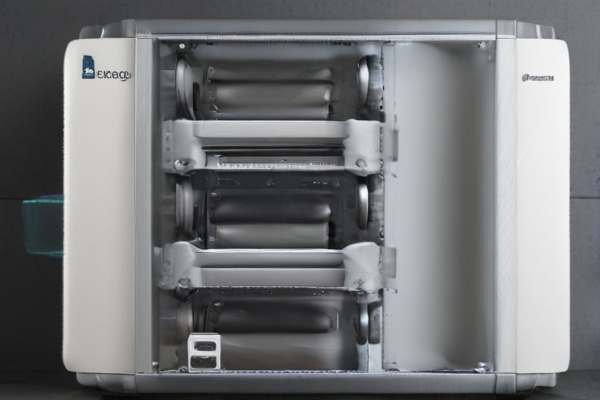

2. How does SourcifyChina ensure the quality of their bag machines?

SourcifyChina employs strict quality control procedures, advanced manufacturing technologies, and rigorous testing to ensure all bag machines meet high-quality standards.

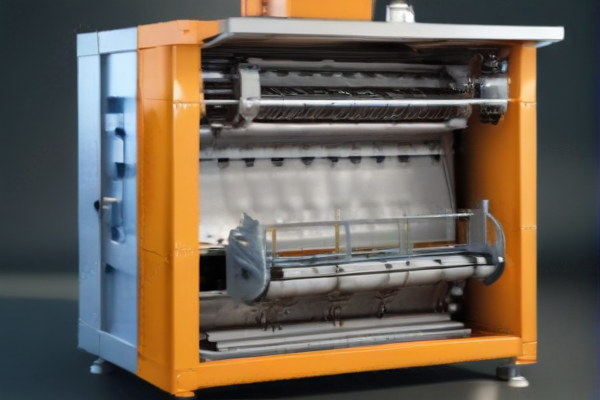

3. What materials are compatible with SourcifyChina’s bag machines?

Our machines are compatible with various materials, such as non-woven fabric, paper, plastic, and other customizable materials depending on client requirements.

4. Do the bag machines from SourcifyChina support customization?

Yes, SourcifyChina offers customization options to meet specific client needs, including custom sizes, designs, and additional features.

5. What kind of after-sales support does SourcifyChina provide?

We offer comprehensive after-sales support, including installation guidance, technical support, maintenance services, and spare parts supply.

6. Are the bag machines energy-efficient?

SourcifyChina designs its bag machines with energy efficiency in mind, ensuring they consume minimal power while maximizing productivity.

7. How long does it take to deliver a bag machine after placing an order?

Delivery times vary depending on machine complexity and order specifications, but typically range from 4 to 8 weeks.

8. Can I visit the SourcifyChina factory to see the manufacturing process?

Yes, we welcome clients to visit our factory. Please contact us to schedule a visit and we’ll gladly arrange it for you.

9. What payment methods does SourcifyChina accept?

We accept various payment methods, including wire transfers, PayPal, and letters of credit.

10. How can I place an order with SourcifyChina?

Orders can be placed by contacting our sales team through email, phone, or our website to discuss your specific requirements and obtain a quote.