Sure, here is a concise FAQ for sourcing a bagger machine from SourcifyChina factory:

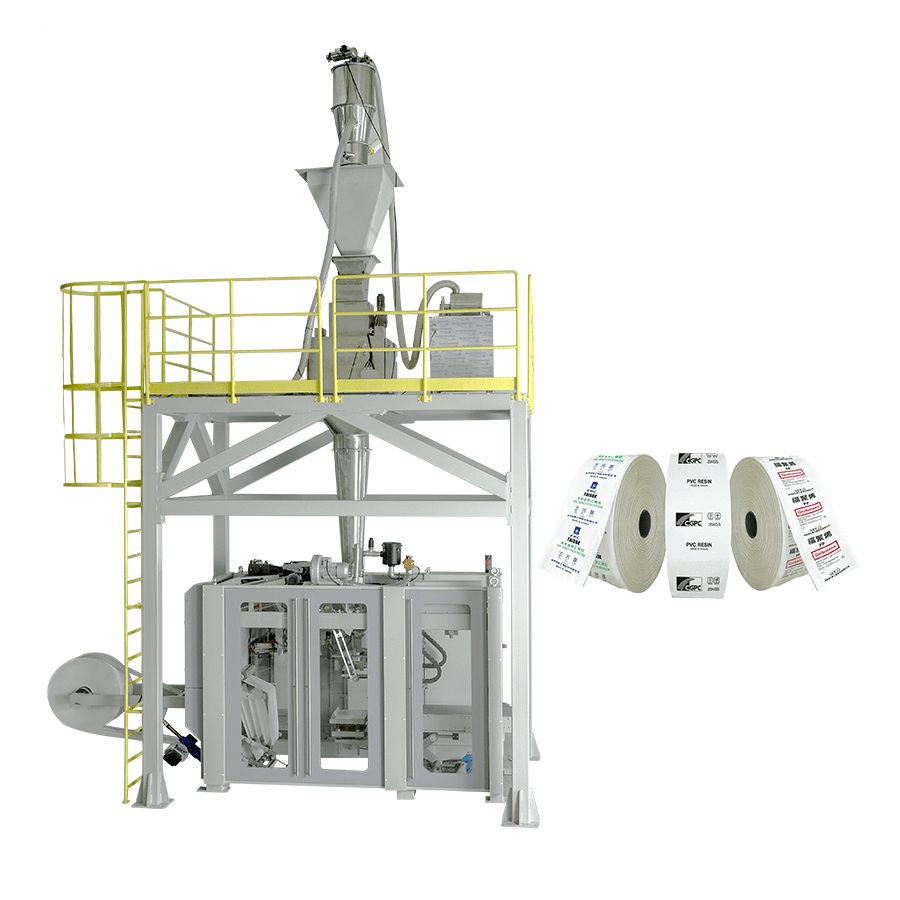

Q: What types of bagger machines does SourcifyChina factory offer?

A: SourcifyChina factory offers a variety of bagger machines including vertical form fill seal machines, horizontal flow wrappers, vacuum baggers, and more, catering to different packaging needs.

Q: How can I request a quote for a bagger machine?

A: You can request a quote by visiting SourcifyChina factory’s website and filling out the contact form with your specific requirements or by directly emailing their sales team.

Q: What information do I need to provide when requesting a quote?

A: Provide details about the type of bagger machine, production capacity, materials to be used, specific features required, and any customization needs.

Q: Does SourcifyChina factory offer customization for bagger machines?

A: Yes, SourcifyChina factory provides customization options to tailor the bagger machines according to your specific requirements and production processes.

Q: What is the typical lead time for delivery?

A: The lead time varies depending on the complexity and customization of the machine, but generally, it ranges from 4 to 8 weeks.

Q: Are there any warranties on the bagger machines?

A: Yes, SourcifyChina factory offers a warranty period for their machines, typically covering parts and labor, details of which can be obtained from their sales team.

Q: Do they provide technical support and training?

A: Yes, SourcifyChina factory provides technical support and can arrange training sessions for your team to ensure smooth operation of the bagger machines.

Q: How is shipping handled?

A: Shipping can be arranged by SourcifyChina factory, and they offer various shipping options including air and sea freight, depending on your preferences and urgency.

Q: What payment methods are accepted?

A: SourcifyChina factory accepts various payment methods such as bank transfer (T/T), Letter of Credit (L/C), and sometimes PayPal, depending on the agreement.

Q: Can I visit the factory for an inspection?

A: Yes, factory visits can be arranged. It’s advised to schedule an appointment in advance for a guided tour and detailed discussion about your needs.