Sure, here is a concise FAQ for sourcing bagging machinery from SourcifyChina factory:

Q1: What types of bagging machinery does SourcifyChina offer?

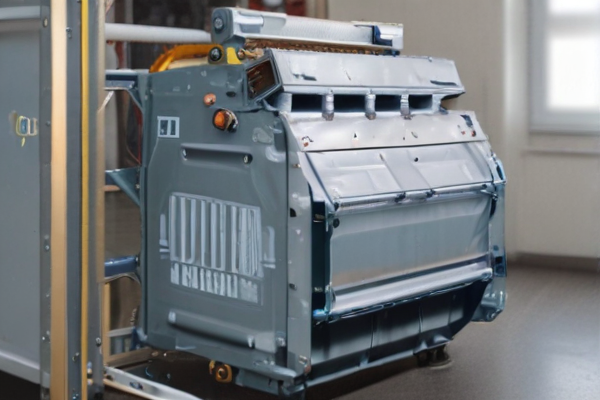

A1: SourcifyChina provides a wide range of bagging machinery including automatic bagging machines, semi-automatic baggers, vertical form fill seal machines, and horizontal bagging systems. They cater to various industries such as food, pharmaceuticals, and chemicals.

Q2: How do I get a quotation for the machinery?

A2: To get a quotation, you need to submit an inquiry through SourcifyChina’s website or contact their sales team directly. Provide detailed information about your requirements, including the type of product, packaging material, and desired production capacity.

Q3: Does SourcifyChina offer customization options for the machinery?

A3: Yes, SourcifyChina offers customization to meet specific needs. You can discuss your requirements with their technical team to tailor the machinery according to your production needs and space constraints.

Q4: What is the typical lead time for delivery?

A4: The standard lead time for delivery is usually between 6 to 12 weeks, depending on the complexity and customization of the machinery. It is advisable to confirm the exact lead time when placing your order.

Q5: What payment methods are accepted?

A5: SourcifyChina accepts various payment methods including wire transfer (T/T), Letter of Credit (L/C), and sometimes PayPal for smaller transactions. Payment terms are typically negotiated during the order process.

Q6: Is installation and training provided?

A6: Yes, SourcifyChina offers on-site installation and training services. Their engineers can assist with setting up the machinery and training your staff to ensure smooth operation.

Q7: How does SourcifyChina handle maintenance and after-sales support?

A7: SourcifyChina provides robust after-sales support, including remote troubleshooting, on-site service visits, and supply of spare parts. They offer maintenance packages to ensure your machinery runs efficiently.

Q8: What warranty terms are available?

A8: SourcifyChina typically offers a one-year warranty on their machinery against manufacturing defects. Extended warranty options may also be available upon request.

Q9: Can sample testing be arranged before purchase?

A9: Yes, SourcifyChina can arrange for sample testing at their facility to demonstrate the machinery’s performance with your specific product.