Sure, here is a concise Frequently Asked Questions (FAQ) list regarding the quality of blister packing machines manufactured by SourcifyChina factory:

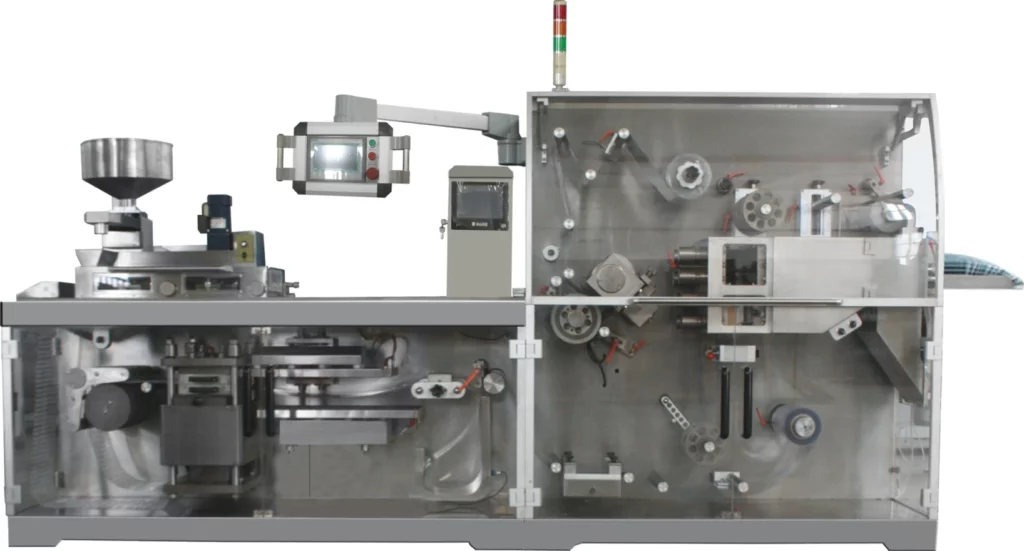

1. What materials are used in manufacturing blister packing machines at SourcifyChina?

SourcifyChina uses high-quality stainless steel and robust industrial-grade components to ensure the durability and longevity of its blister packing machines.

2. How does SourcifyChina ensure the quality of its blister packing machines?

SourcifyChina adheres to strict quality control protocols, including multiple inspections at various stages of production, and complies with international standards like ISO 9001.

3. Are the machines equipped with advanced technology?

Yes, SourcifyChina integrates the latest technology in its blister packing machines, including PLC systems, touch screen interfaces, and automated tracking to enhance efficiency and precision.

4. Can the blister packing machines be customized for specific needs?

Yes, SourcifyChina offers customization options to meet clients’ specific packaging requirements, such as different sizes, configurations, and capacities.

5. What kind of support does SourcifyChina provide post-purchase?

SourcifyChina provides comprehensive after-sales support, including installation assistance, operator training, regular maintenance advice, and access to technical support and spare parts.

6. How energy-efficient are the blister packing machines?

SourcifyChina designs its machines with energy efficiency in mind, incorporating features that minimize power consumption while maintaining high performance.

7. Are the machines easy to operate?

Yes, SourcifyChina’s blister packing machines are designed with user-friendly interfaces and straightforward controls, ensuring ease of operation and minimal training requirements.

8. What is the warranty period for SourcifyChina’s blister packing machines?

SourcifyChina offers a standard one-year warranty on its blister packing machines, covering manufacturing defects and providing peace of mind to customers.

9. How long does it take to manufacture and deliver a machine?

The manufacturing and delivery timeline varies depending on the complexity and customization, but standard models typically take around 4-6 weeks.

10. What industries use SourcifyChina’s blister packing machines?

SourcifyChina’s blister packing machines are widely used in pharmaceutical, food, cosmetic, and hardware industries to package products efficiently and securely.

This list provides a quick overview of commonly asked questions and answers for potential buyers of blister packing machines from SourcifyChina factory.