Sure, here are some frequently asked questions (FAQ) with their answers for sourcing a “bottle filling machine from SourcifyChina factory”:

1. What types of bottle filling machines are available at SourcifyChina?

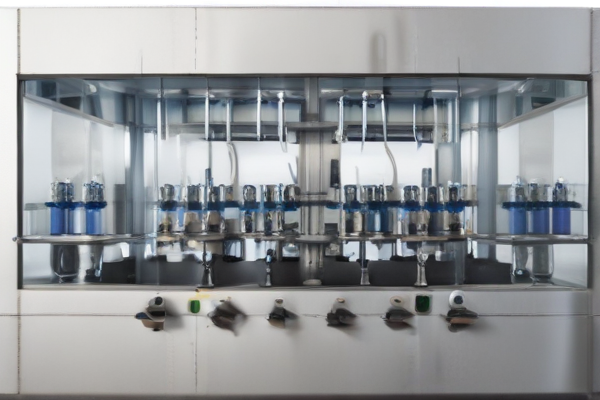

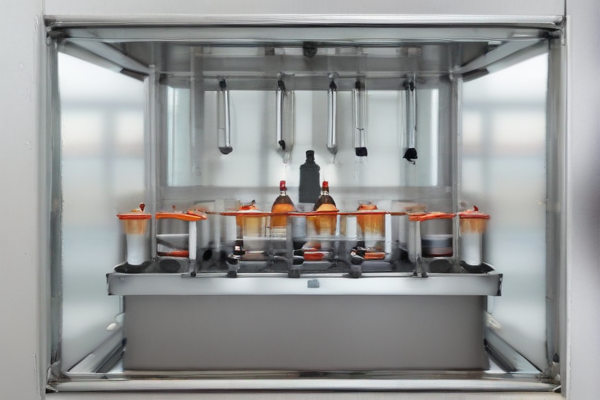

SourcifyChina offers a range of bottle filling machines, including automatic, semi-automatic, and manual machines. These can handle different bottle types, sizes, and materials such as glass, plastic, and metal.

2. How do I request a quote for a bottle filling machine?

To request a quote, you can visit SourcifyChina’s official website, fill out the inquiry form with your specifications, or contact their sales team directly via email or phone.

3. What information do I need to provide for an accurate quote?

You should provide details like the type of liquid to be filled, bottle size, production capacity, automation level required, and any special features or specifications.

4. Are there any minimum order requirements?

SourcifyChina typically requires a minimum order quantity (MOQ), which varies depending on the machine model and customization level. It’s best to confirm the MOQ during the initial inquiry.

5. What is the lead time for manufacturing and delivering the machine?

The lead time depends on the complexity of the machine and current order volume but generally ranges from 4 to 8 weeks.

6. How is the machine shipped?

SourcifyChina usually ships machines via sea freight or air freight, depending on the customer’s preference and urgency. They also handle packaging to ensure the machine’s safe arrival.

7. Is there any warranty or after-sales service provided?

Yes, all machines come with a standard warranty period, usually one year. SourcifyChina also provides after-sales support, including installation guidance, maintenance, and troubleshooting services.

8. Can I visit the factory for a tour or inspection?

Yes, SourcifyChina welcomes potential buyers to visit their factory. You can schedule a visit by contacting their customer service team in advance.

9. What payment methods are accepted?

SourcifyChina accepts various payment methods including T/T (bank transfer), L/C (letter of credit), and sometimes PayPal or credit card, depending on the agreement.

10. Are there options for customization?

Yes, SourcifyChina offers customization based on your specific needs, including changes in machine size, filling speed, control systems, and additional features.