Certainly! Here are some frequently asked questions (FAQ) along with their answers for sourcing a bottle label applicator machine from the SourcifyChina factory.

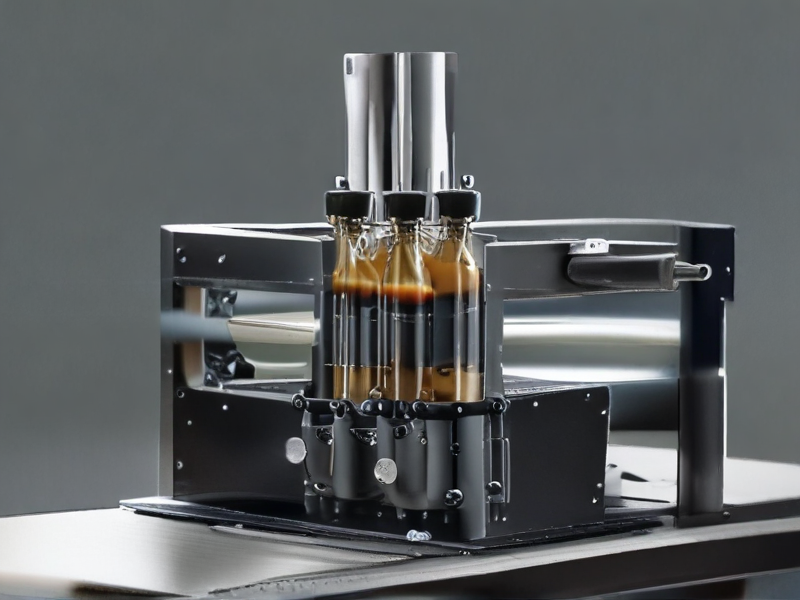

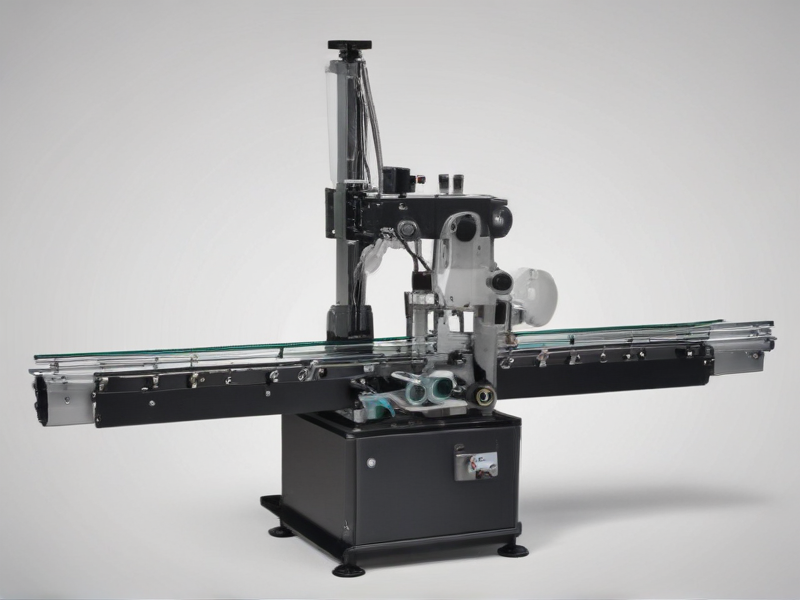

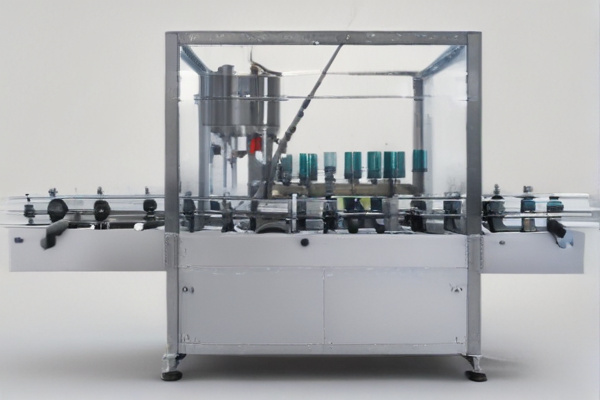

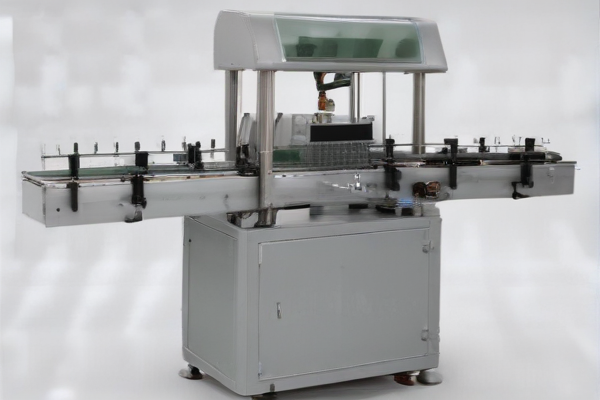

Q: What types of bottle label applicator machines does SourcifyChina offer?

A: SourcifyChina offers a range of bottle label applicator machines including semi-automatic, fully automatic, and custom solutions to handle various bottle shapes and sizes.

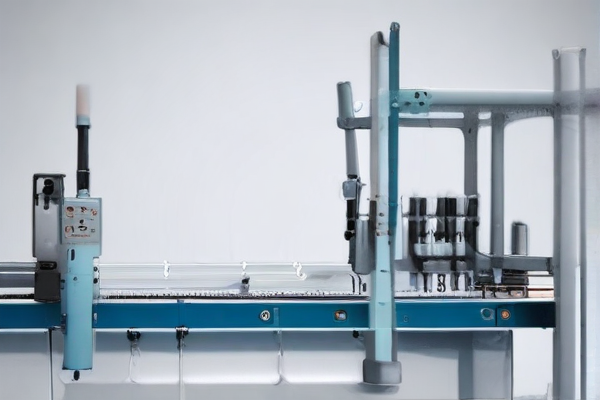

Q: Can the machines handle different bottle shapes and sizes?

A: Yes, the machines are versatile and can be adjusted to accommodate round, square, and uniquely shaped bottles of various sizes.

Q: What is the typical lead time for delivery?

A: The standard lead time is approximately 30-45 days from order confirmation, but this may vary based on customization requirements and order volume.

Q: Is it possible to request a machine demonstration?

A: Yes, SourcifyChina can provide a virtual demonstration via video call or share demonstration videos upon request.

Q: What kind of technical support is available post-purchase?

A: SourcifyChina offers comprehensive technical support including remote troubleshooting, online guidance, and spare parts supply.

Q: Can I customize the machine to suit my specific labeling needs?

A: Absolutely, SourcifyChina provides customization options to ensure the machines meet your unique requirements for speed, precision, and design.

Q: What are the payment terms?

A: Payment terms typically include a 30% deposit upon order confirmation and the remaining 70% before shipment, but variations can be discussed directly with the sales team.

Q: Does SourcifyChina provide installation and training services?

A: Yes, installation and training services can be provided either on-site or remotely, depending on your location and needs.

Q: What warranty does SourcifyChina offer on the bottle label applicator machines?

A: Most machines come with a standard one-year warranty covering parts and labor. Extended warranties can be negotiated as well.

Q: How can I get a quote for a bottle label applicator machine?

A: You can get a quote by contacting SourcifyChina via their website, email, or telephone. Providing details about your specific requirements will ensure a more accurate quote.

This FAQ should help you understand the key aspects of sourcing a bottle label applicator machine from SourcifyChina.