Here are the FAQs for sourcing a bottle labeler machine from SourcifyChina factory:

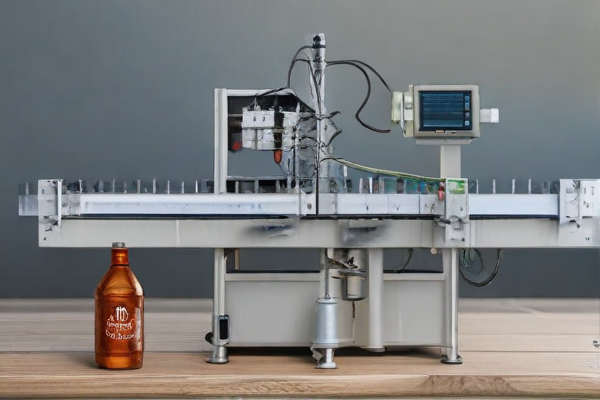

Q1: What types of bottle labeler machines are available?

A1: SourcifyChina offers a variety of bottle labeler machines, including automatic, semi-automatic, and manual models. These machines cater to different production scales and labeling needs.

Q2: How can I get a quote for a bottle labeler machine?

A2: To get a quote, visit our website and fill out the inquiry form with your specifications or contact our sales team directly via email or phone.

Q3: What information do I need to provide for a quote?

A3: Provide information such as the type of bottles, labeling speed, label dimensions, preferred automation level, and any special requirements.

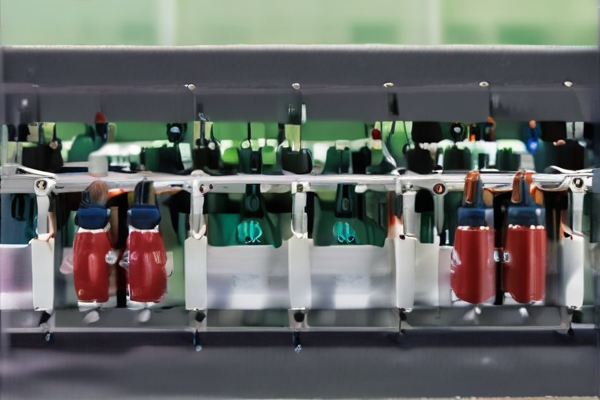

Q4: Are there customization options available?

A4: Yes, SourcifyChina offers customization options to meet specific requirements, including adjustments for different bottle shapes and label types.

Q5: What is the lead time for production and delivery?

A5: The usual lead time is 4-6 weeks for production, plus additional time for shipping, depending on your location.

Q6: Do you offer after-sales service and support?

A6: Yes, we provide comprehensive after-sales support, including training, installation services, and maintenance.

Q7: What are the payment terms?

A7: Payment terms typically include a down payment upon order confirmation and the remaining balance before shipment. Specific terms can be discussed with our sales team.

Q8: Is there a warranty for the machines?

A8: Yes, all our bottle labeler machines come with a one-year warranty covering parts and labor.

Q9: Can I see the machine before purchasing?

A9: Virtual demonstrations can be arranged. For on-site visits, contact our sales team to schedule an appointment.

Q10: How do I ensure the machine meets my quality standards?

A10: We provide detailed product specifications, quality certifications, and sample testing to ensure the machine meets your standards before finalizing the purchase.