Q: What types of bottle labeling equipment does SourcifyChina factory offer?

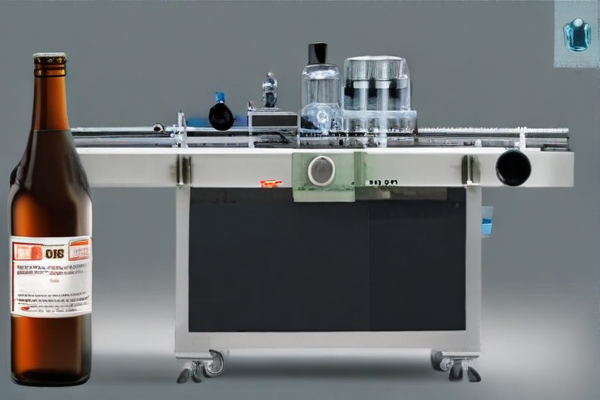

A: SourcifyChina factory offers various types of bottle labeling equipment, including automatic, semi-automatic, and manual labeling machines. These machines can handle different bottle shapes and sizes, from round to irregularly shaped containers.

Q: What materials can the labeling machines handle?

A: The labeling machines from SourcifyChina factory can handle various materials such as glass, plastic, metal, and composite bottles.

Q: Are customizations available for the labeling equipment?

A: Yes, SourcifyChina factory provides customization options to meet specific requirements. You can discuss your needs with their team to tailor the machine according to your production line.

Q: What is the lead time for sourcing bottle labeling equipment?

A: The lead time typically varies based on the complexity of the machine and customization requirements but usually ranges from 4 to 8 weeks.

Q: Does SourcifyChina factory offer installation and training services?

A: Yes, SourcifyChina factory provides installation and training services. They ensure that your team is well-versed in operating the equipment for optimal performance.

Q: What is the warranty period for the bottle labeling equipment?

A: The warranty period for the bottle labeling equipment is typically 12 months from the date of purchase. This may vary based on specific agreements and machine types.

Q: How does SourcifyChina factory ensure the quality of its labeling equipment?

A: SourcifyChina factory follows strict quality control measures and international standards. Each machine undergoes rigorous testing before shipment to guarantee reliability and performance.

Q: What after-sales support does SourcifyChina factory offer?

A: SourcifyChina factory offers comprehensive after-sales support, including technical assistance, parts replacement, and maintenance services.

Q: Can SourcifyChina factory ship internationally?

A: Yes, SourcifyChina factory can ship products internationally. They collaborate with reputable logistics companies to ensure safe and timely delivery.

Q: How do I place an order with SourcifyChina factory?

A: You can place an order by contacting SourcifyChina factory directly via their website, email, or phone. A sales representative will guide you through the ordering process and discuss details such as machine specifications, pricing, and delivery.