Sourcing a bottle labeling machine from SourcifyChina can be streamlined with a few strategic steps:

1. Clearly Define Your Requirements:

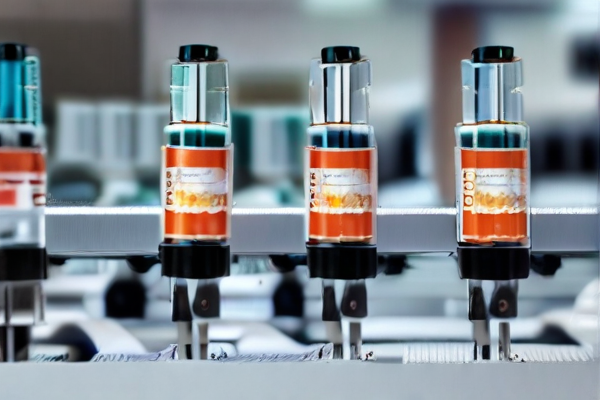

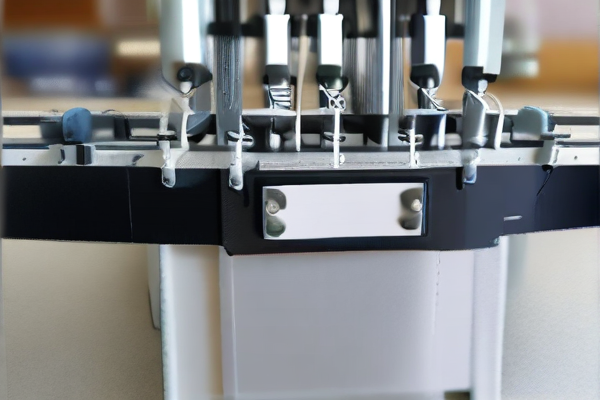

– Determine the type of bottle labeling machine you need (e.g., automatic, semi-automatic, wrap-around, front-back).

– Specify the production capacity and label size requirements.

2. Research and Shortlist Suppliers:

– Contact SourcifyChina, providing your detailed requirements to ensure they understand your needs.

– Request product catalogs and technical specifications.

– Check for certifications, quality standards, and compliance with industry regulations.

3. Evaluate Supplier Credentials:

– Verify the factory’s experience in manufacturing labeling machines.

– Look for customer reviews or testimonials to gauge reputation.

– Inquire about after-sales support and warranty terms.

4. Request Samples or Demos:

– If possible, request a live demo via video call to see the machine in action.

– Ask for samples of labeled bottles to evaluate the quality and precision.

5. Compare Quotes and Payment Terms:

– Obtain detailed quotes, including shipping, taxes, and potential hidden costs.

– Compare pricing, ensuring you’re aware of payment terms, like deposits, installment plans, or L/C.

6. Negotiate and Finalize:

– Negotiate terms ensuring flexibility for any unforeseen changes.

– Clarify delivery timelines to align with your production schedule.

7. Due Diligence and Contract:

– Conduct a background check or factory audit, if feasible.

– Draft a clear contract outlining all responsibilities, specifications, and warranties.

8. Establish Clear Communication:

– Maintain regular communication for updates during production and shipment.

– Use reliable logistics and tracking services to ensure timely delivery.

By following these steps, you can effectively source a high-quality bottle labeling machine from SourcifyChina, maximizing value and minimizing risks.