Certainly! Below is a list of frequently asked questions (FAQs) along with their answers regarding the manufacturing and quality of bottle labeling machines from SourcifyChina Factory:

1. What types of bottle labeling machines does SourcifyChina manufacture?

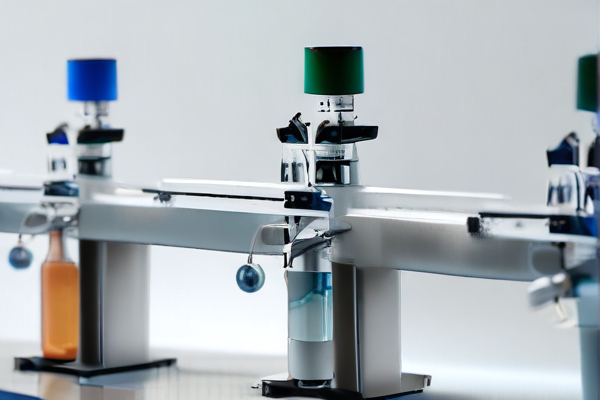

SourcifyChina specializes in a variety of bottle labeling machines, including automatic, semi-automatic, and manual models. These cater to different production volumes and labeling needs.

2. What materials are used in the construction of these labeling machines?

The labeling machines from SourcifyChina are constructed with high-grade stainless steel and aluminum alloy, ensuring durability, stability, and resistance to corrosion.

3. Are the labeling machines compatible with different bottle shapes and sizes?

Yes, SourcifyChina’s labeling machines are highly versatile and can accommodate a wide range of bottle shapes and sizes, including cylindrical, square, and uniquely shaped bottles.

4. How does SourcifyChina ensure the quality of its labeling machines?

Quality assurance is a top priority. Each machine undergoes rigorous testing and inspection during and after the manufacturing process. SourcifyChina adheres to international quality standards like ISO 9001:2015.

5. Can these labeling machines handle different types of labels?

Absolutely. The machines are designed to work with various label types, including paper, plastic, and foil labels. They can also handle self-adhesive, shrink-sleeve, and wrap-around labels.

6. What is the typical lead time for an order?

The lead time varies based on the machine model and order quantity. However, typical lead times range from 4 to 8 weeks from the date of order confirmation.

7. Do you provide training and technical support?

Yes, SourcifyChina offers comprehensive training and technical support for all its machines. This includes on-site installation, user manuals, and continuous remote support.

8. What kind of warranty does SourcifyChina offer?

SourcifyChina provides a standard one-year warranty on all its labeling machines, covering any manufacturing defects and offering free spare parts during the warranty period.

9. Can customization be requested for specific needs?

Yes, customization is available to meet specific requirements. Clients can discuss their unique needs, and SourcifyChina’s engineering team will design a customized solution.

10. How do I place an order or request a quote?