Sure, here is a list of frequently asked questions (FAQ) about sourcing a box erector machine with quality assurance from SourcifyChina factory. Each question is marked with `` tags.

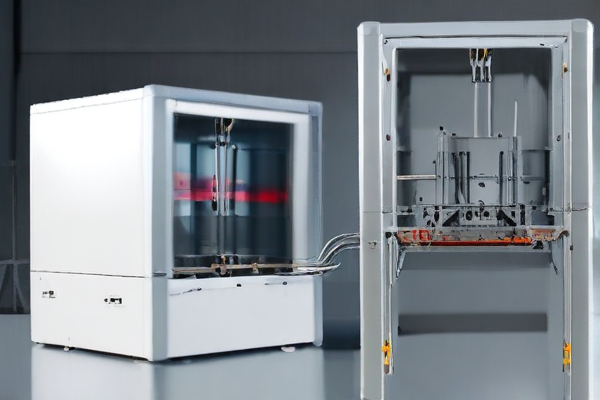

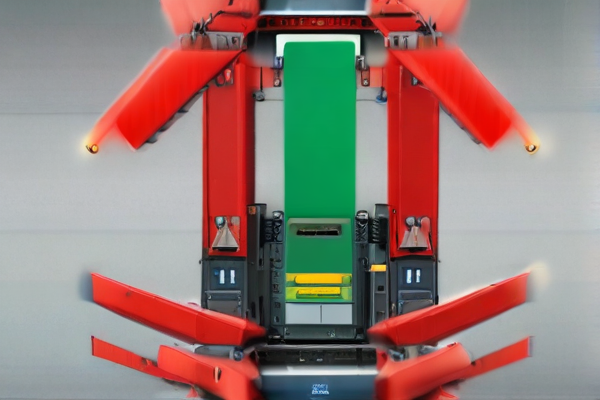

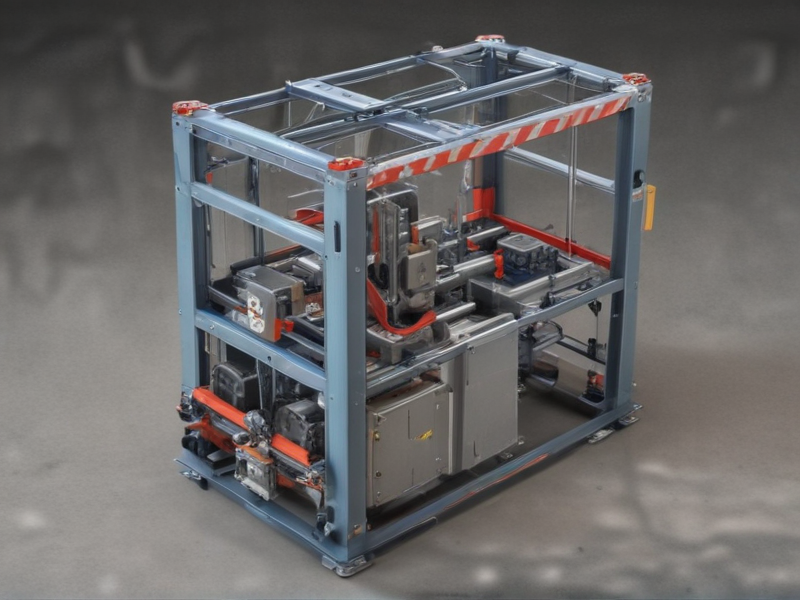

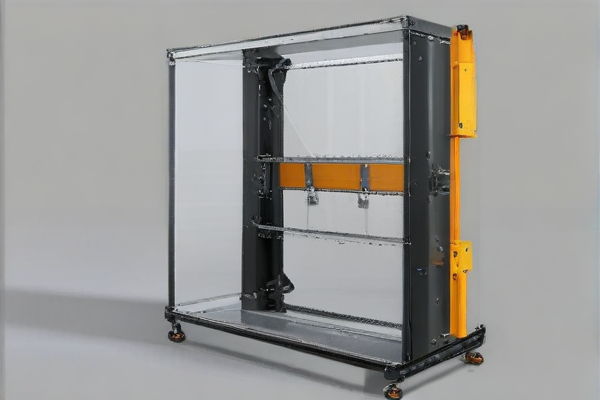

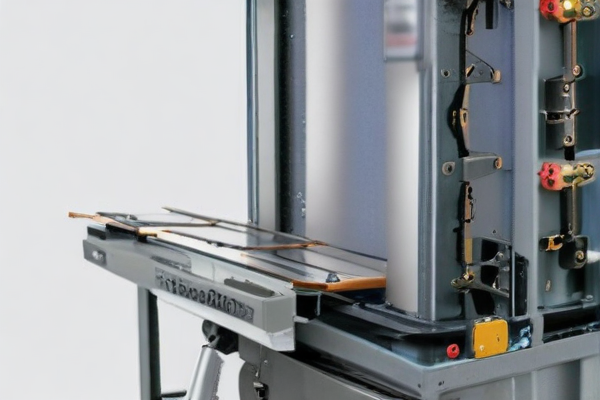

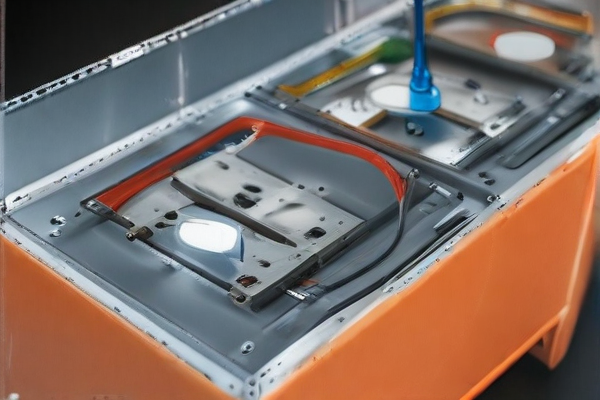

1. What is a box erector machine?

A box erector machine is an automated device that assembles flat cardboard into a 3-dimensional box. It folds the flaps and seals the bottom, making the boxes ready for packaging.

2. Why choose SourcifyChina for a box erector machine?

SourcifyChina is known for its high-quality manufacturing standards, competitive pricing, and reliable customer service. They adhere to international quality standards, ensuring the durability and efficiency of their machines.

3. How do I ensure the quality of the box erector machine from SourcifyChina?

SourcifyChina provides detailed product specifications and quality certifications. They offer pre-shipment inspections, and you can request sample machines or onsite visits to verify quality.

4. What are the lead times for manufacturing and delivery?

The lead time varies based on order quantity and customization requirements but typically ranges from 4 to 8 weeks. Shipping times depend on the destination country and shipping method selected.

5. Can the box erector machine be customized?

Yes, SourcifyChina offers customization options to fit your specific packaging needs, including modifications in size, speed, and additional features like safety systems or integration with existing production lines.

6. What kind of after-sales support does SourcifyChina provide?

They offer comprehensive after-sales support, including installation assistance, training for operators, and a warranty period during which they provide free parts and labor for repairs.

7. How do I request a quote?

You can request a quote by contacting SourcifyChina directly through their website, email, or phone. Provide detailed requirements to receive an accurate quotation.

8. Are there any bulk purchase discounts available?

Yes, SourcifyChina offers discounts for bulk purchases. The discount rate depends on the order size and terms of the agreement.

9. What payment methods are accepted?

SourcifyChina accepts multiple payment methods including bank transfers, letters of credit, and sometimes even credit card payments, subject to negotiation.

10. How does SourcifyChina ensure timely delivery?

They utilize a well-coordinated logistics network and provide regular updates on the manufacturing and shipping status to ensure timely delivery.