Sure! Here is a list of Frequently Asked Questions (FAQ) with answers for sourcing can filling machines from SourcifyChina factory:

Q: What types of can filling machines does SourcifyChina offer?

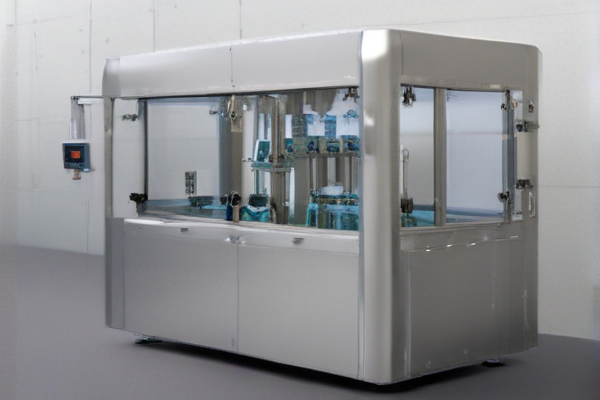

A: SourcifyChina provides a wide range of can filling machines including semi-automatic, fully automatic, and custom-designed filling machines catering to different production capacities and types of liquids such as beverages, oils, and chemicals.

Q: Are the can filling machines customizable?

A: Yes, SourcifyChina offers customization options to meet specific production needs, including machine size, filling volume, speed, and additional features like capping and labeling.

Q: What is the lead time for a can filling machine order?

A: The lead time generally ranges from 4 to 8 weeks depending on the model and customization requirements. It is recommended to contact SourcifyChina directly for the most accurate delivery estimate.

Q: Does SourcifyChina provide installation and training services?

A: Yes, SourcifyChina offers on-site installation and comprehensive training for operators to ensure smooth and efficient use of the can filling machines.

Q: What are the payment terms?

A: Payment terms typically include an initial deposit followed by balance payment upon shipment. Detailed terms can be discussed and negotiated with SourcifyChina’s sales team.

Q: What kind of warranty and after-sales support is available?

A: SourcifyChina provides a one-year warranty on all can filling machines. Additionally, they offer ongoing technical support, spare parts supply, and maintenance services to ensure long-term operational reliability.

Q: How can I ensure the quality of the can filling machines?

A: SourcifyChina follows stringent quality control processes including testing each machine before shipment. Customers can request videos, specifications, and even arrange for third-party inspections for added assurance.

Q: What information is needed to get a quote?

A: To receive an accurate quote, provide details such as the type of liquid to be filled, can size, desired production capacity, and any specific customization requirements. This helps SourcifyChina’s team tailor a solution to your needs.

Q: Can I visit the SourcifyChina factory?

A: Yes, factory visits can be arranged upon request. This allows you to see the production processes, meet the team, and discuss your requirements in detail.

For further inquiries, contact SourcifyChina’s customer service team via email or phone listed on their official website.