Q: What is the quality of can labeling machines from SourcifyChina factory?

A: SourcifyChina is known for manufacturing high-quality can labeling machines. They adhere to stringent quality control measures and use robust materials to ensure durability and reliable performance.

Q: Are the machines from SourcifyChina compliant with international standards?

A: Yes, SourcifyChina ensures that their can labeling machines meet international standards, including CE and ISO certifications, to guarantee safety and performance.

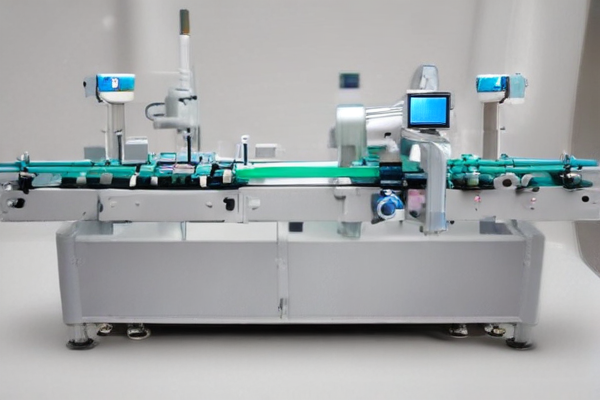

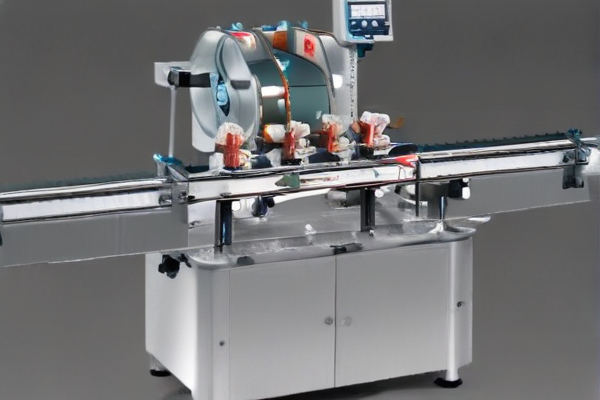

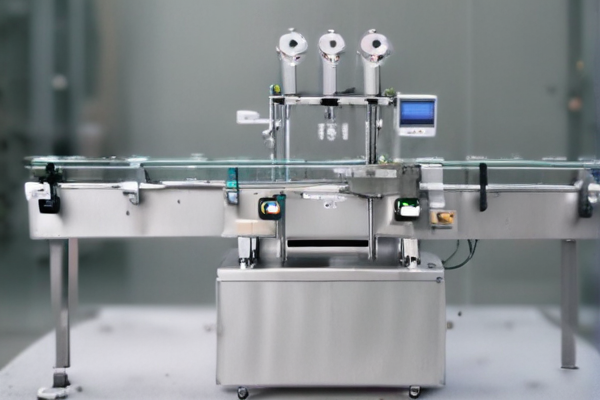

Q: What types of can labeling machines does SourcifyChina offer?

A: SourcifyChina offers a range of can labeling machines, including automatic, semi-automatic, and manual options, tailored to meet various production needs and budget requirements.

Q: Is there a warranty on the can labeling machines from SourcifyChina?

A: Yes, SourcifyChina provides a warranty on their can labeling machines, typically covering 1-2 years for manufacturing defects and parts replacement.

Q: How does SourcifyChina support after-sales service?

A: SourcifyChina offers comprehensive after-sales support including technical assistance, spare parts supply, and maintenance services to ensure optimal machine performance throughout its lifecycle.

Q: Can SourcifyChina customize can labeling machines according to specific requirements?

A: Yes, SourcifyChina provides customization services to meet specific labeling requirements, such as different can sizes, shapes, and labeling types, ensuring a perfect fit for your production line.

Q: What is the lead time for delivering a can labeling machine from SourcifyChina?

A: The lead time varies depending on the machine model and customization needs, but typically ranges from 4 to 8 weeks.

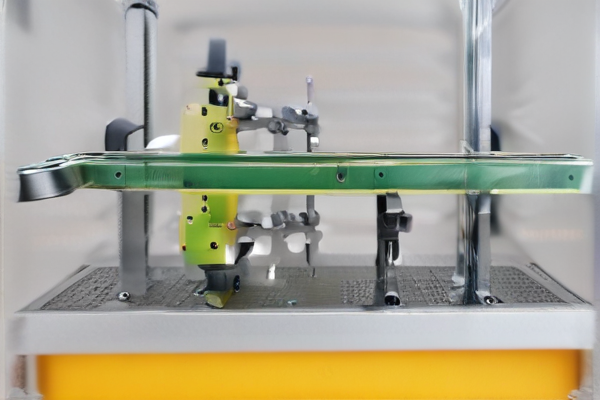

Q: How does SourcifyChina ensure the reliability of their can labeling machines?

A: SourcifyChina employs advanced manufacturing techniques and rigorous testing procedures to ensure that each can labeling machine is reliable and performs consistently under various operating conditions.

Q: What is the cost range for can labeling machines from SourcifyChina?

A: The cost of can labeling machines from SourcifyChina varies based on the model and customization options. They offer competitive pricing to cater to different budget ranges while maintaining high quality.

Q: How can I place an order for a can labeling machine with SourcifyChina?