When considering can seamer machine manufacturing from SourcifyChina factory, here are some essential tips to keep in mind:

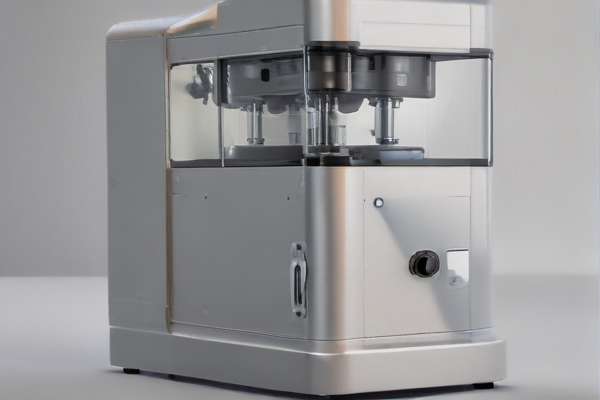

1. Define Your Requirements:

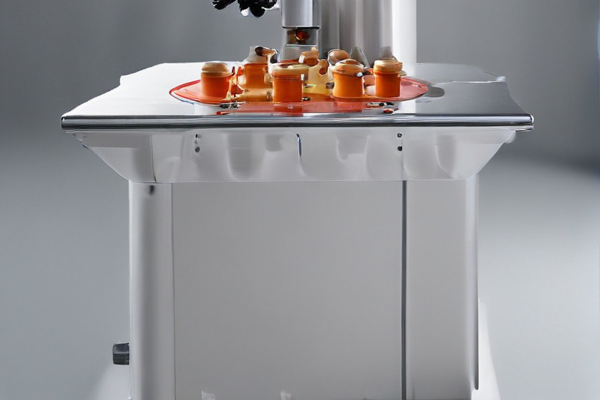

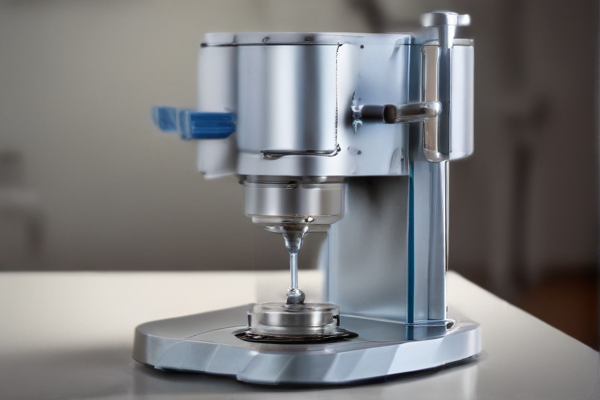

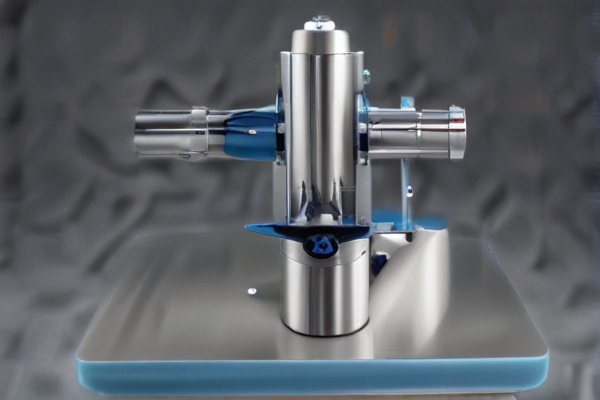

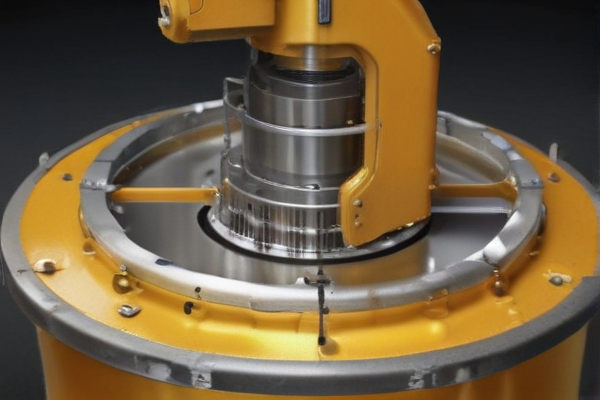

– Clearly outline the specifications and capacity requirements for your can seamer machinery. Consider the type and size of cans, production speed, and any additional functionalities needed (e.g., sealing integrity, automation level).

2. Quality and Compliance:

– Ensure the machines adhere to international quality standards and certifications (e.g., ISO, CE). Check for compliance with food safety regulations if applicable.

3. Customization Options:

– Inquire about customization capabilities to tailor the machine to your specific production needs. SourcifyChina offers flexible design modifications to meet diverse industrial requirements.

4. Technical Support and Service:

– Evaluate the after-sales support and technical service. Reliable support includes installation assistance, training, troubleshooting, and maintenance services.

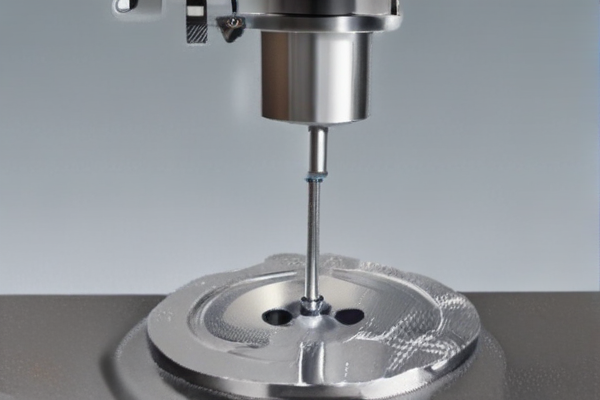

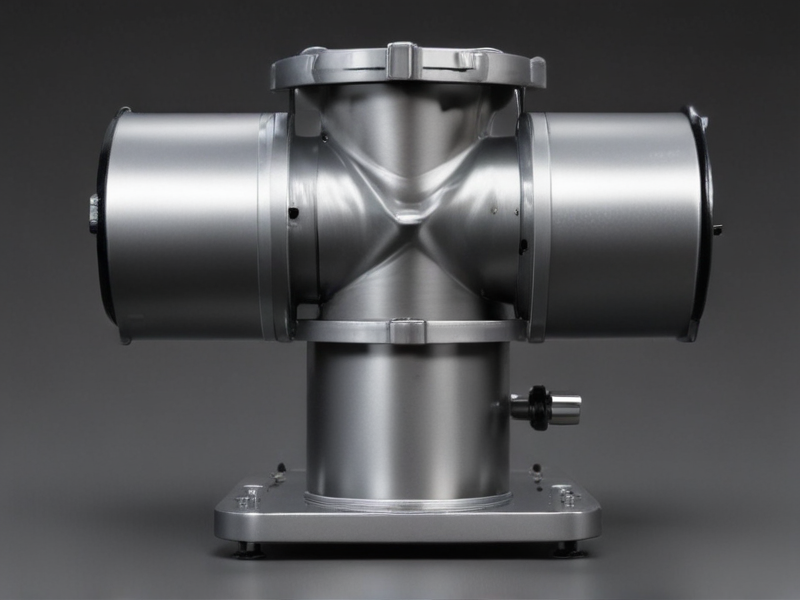

5. Material and Build Quality:

– Confirm the use of durable materials and robust construction for long-term operation. Stainless steel is a preferred material for food and beverage applications due to its corrosion resistance.

6. Efficiency and Energy Consumption:

– Opt for machines designed for high efficiency and low energy consumption to ensure cost-effective operation.

7. Reputation and References:

– Research SourcifyChina’s market reputation and ask for references or case studies from past clients. Positive feedback and proven track records are good indicators of reliability.

8. Price and Payment Terms:

– Compare pricing structures, ensuring they provide good value for money. Negotiate favorable payment terms and check for hidden costs.

9. Spare Parts Availability:

– Verify the availability and cost of spare parts to prevent extended downtimes in case of machine failures.

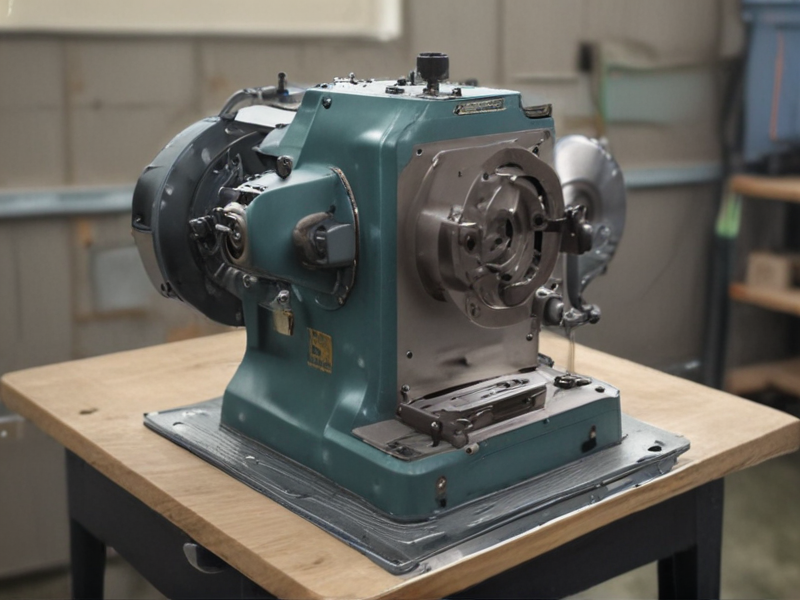

10. Visit the Factory:

– If possible, visit the SorcifyChina factory for an on-site evaluation of their manufacturing practices, quality controls, and facilities.

By following these tips, you can navigate the process more effectively and ensure you get a high-quality can seamer machine suited to your production needs.