Sure, below is an FAQ list for sourcing a can seaming machine from SourcifyChina factory:

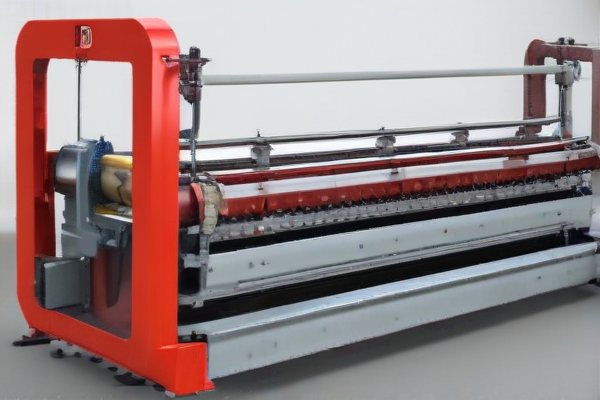

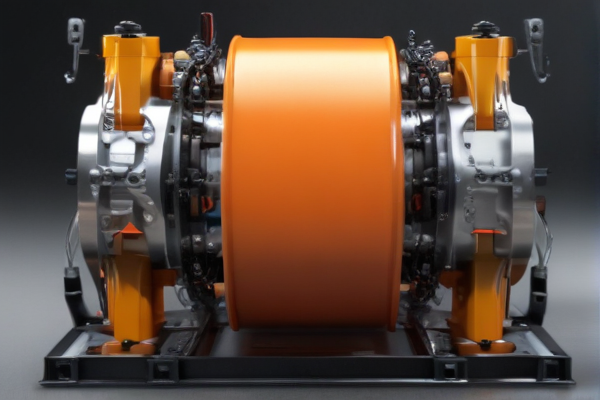

Q: What types of can seaming machines does SourcifyChina factory offer?

A: SourcifyChina factory offers a variety of can seaming machines, including semi-automatic and fully automatic models, suitable for different production capacities and types of cans.

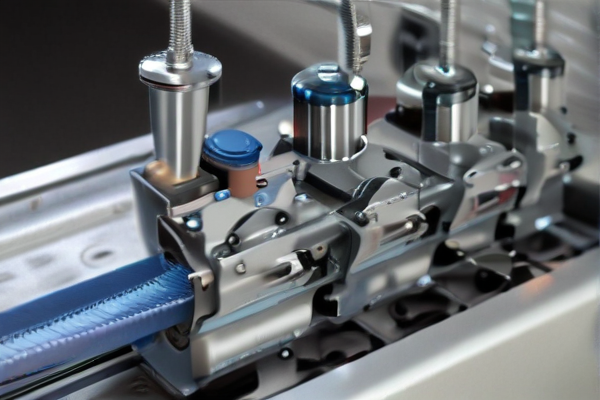

Q: Are the machines customizable?

A: Yes, SourcifyChina factory provides customization options to meet specific requirements such as size, speed, and additional features.

Q: What is the lead time for an order?

A: The lead time varies based on the complexity and quantity of the order but typically ranges from 4 to 8 weeks.

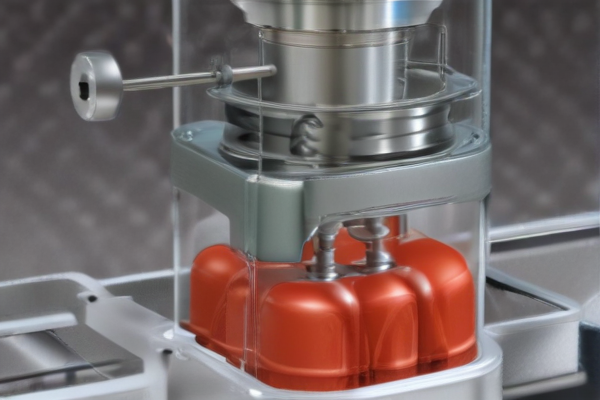

Q: What is the quality assurance process?

A: SourcifyChina conducts stringent quality checks, including material inspection, functionality tests, and final quality control before shipment to ensure high standards.

Q: Is there a minimum order quantity (MOQ)?

A: The MOQ may vary based on the model and customization requirements. It’s best to contact SourcifyChina directly for specific details.

Q: What payment methods are accepted?

A: SourcifyChina accepts multiple payment methods including T/T (Telegraphic Transfer), L/C (Letter of Credit), and in some cases, escrow services.

Q: Do you provide installation and training services?

A: Yes, SourcifyChina offers installation and training services to ensure your team can efficiently operate the machinery.

Q: What warranty and after-sales services are provided?

A: SourcifyChina provides a standard one-year warranty on their machines, along with lifetime technical support and readily available spare parts.

Q: Can I visit the factory before making a purchase?

A: Yes, potential buyers are welcome to visit the SourcifyChina factory to inspect machinery and discuss their requirements in person.

Q: How are the machines shipped and what are the shipping costs?

A: Machines are typically shipped via sea freight. Shipping costs will depend on the destination and size of the order and can be included in the final quotation.

Q: Can the machines handle different can sizes?

A: Yes, many models are versatile and can be adjusted to seam different can sizes. Specific compatibility should be confirmed with SourcifyChina.

Feel free to reach out directly to SourcifyChina with more specific queries or for a personalized consultation.