Certainly! Below are some frequently asked questions (FAQ) about manufacturing candy machinery with quality work from SourcifyChina Factory:

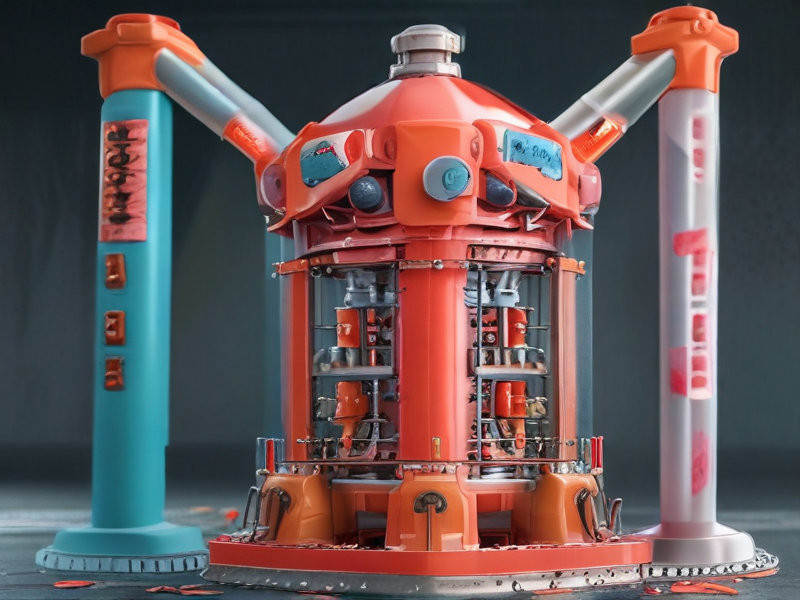

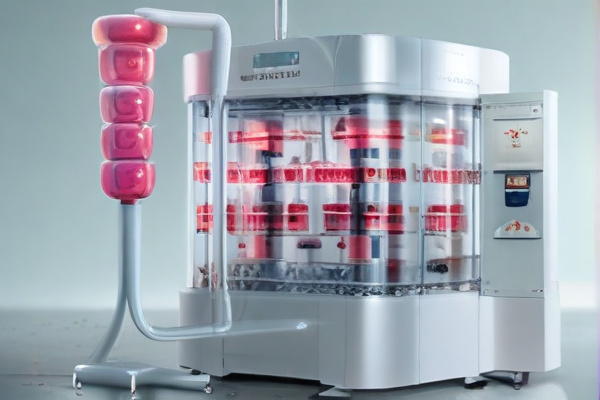

Q1: What types of candy machinery does SourcifyChina manufacture?

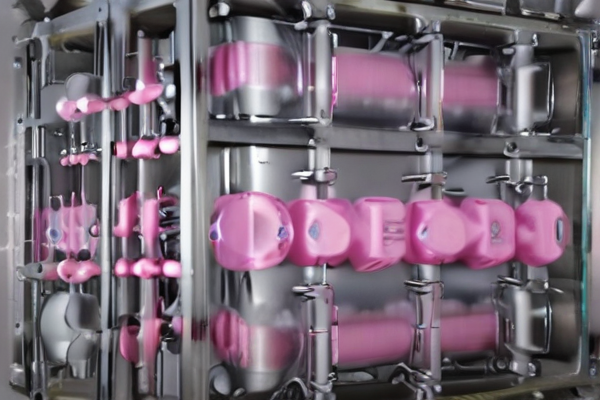

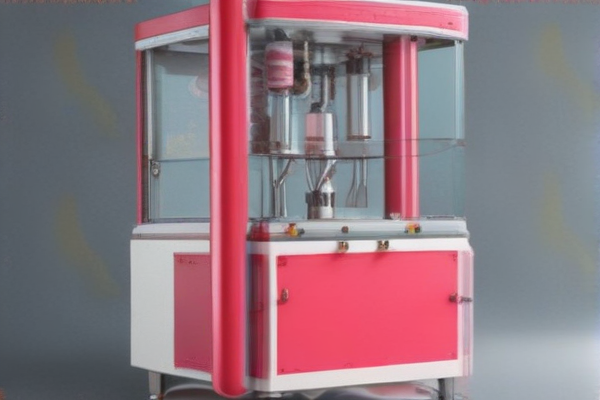

A1: SourcifyChina specializes in a wide range of candy machinery, including but not limited to candy making machines, chocolate molding equipment, sugar coating machines, wrapping machines, and more. We cater to varied candy production needs—from small batches to large-scale industrial operations.

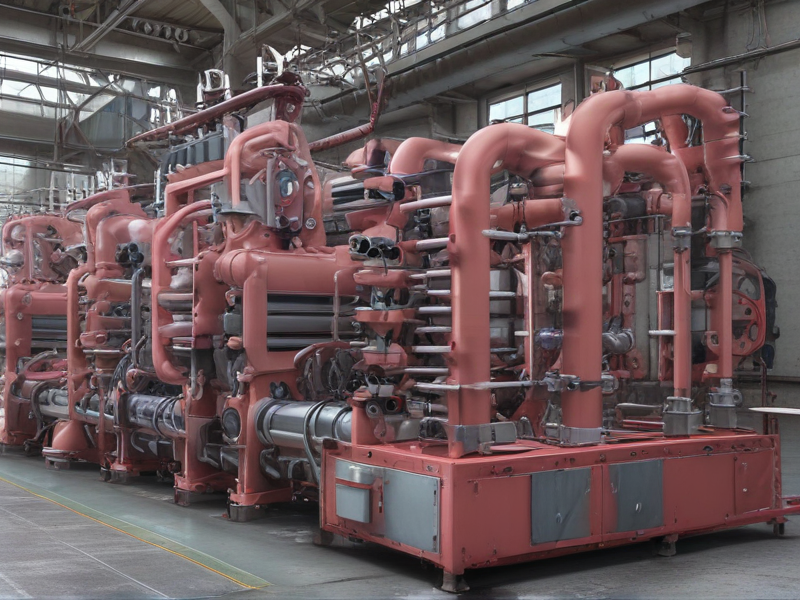

Q2: How does SourcifyChina ensure the quality of their candy machinery?

A2: Quality is at the forefront of our manufacturing process. At SourcifyChina, we adhere to stringent quality control standards. This includes using high-grade materials, advanced manufacturing techniques, and rigorous testing procedures. Additionally, our machinery is ISO-certified and complies with international safety standards.

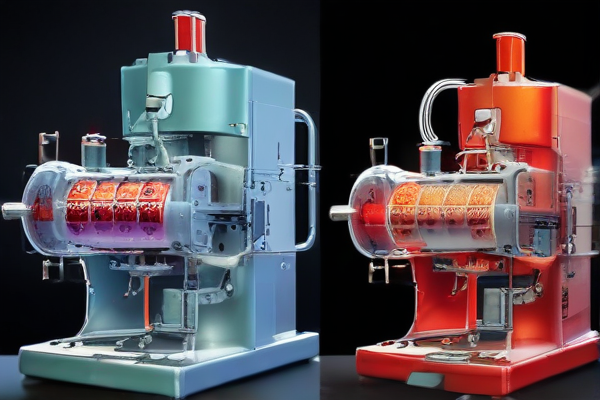

Q3: Can SourcifyChina customize candy machines to specific requirements?

A3: Yes, SourcifyChina offers customization services to meet specific production needs. Whether you require a particular size, capacity, or specialized functions, our team of experienced engineers can design machinery tailored to your unique requirements.

Q4: What is the average lead time for an order?

A4: The lead time varies depending on the complexity and customization of the machinery. However, standard machinery typically has a lead time of 4 to 6 weeks. Customized orders may take longer, for which we provide a detailed timeline during the consultation phase.

Q5: Do you provide after-sales support and services?

A5: Absolutely. SourcifyChina offers comprehensive after-sales support, including installation assistance, training for operators, and maintenance services. Our customer service team is available 24/7 to address any issues or queries you might have.

Q6: Are there any warranties on SourcifyChina candy machinery?

A6: Yes, all our candy machinery comes with a standard one-year warranty, which covers manufacturing defects and performance issues. Extended warranties and service packages are also available upon request.

Q7: How can I get a quote for candy machinery?

A7: To obtain a quote, you can contact us through our website, email, or phone with your specific requirements. Our sales team will provide a detailed quotation based on your needs, including pricing, lead time, and customization options.

Q8: What payment methods does SourcifyChina accept?

A8: We accept various payment methods, including wire transfers, letters of credit, and other secure payment options.