Here are some frequently asked questions (FAQ) about manufacturing cannabis packaging machines with quality work from SourcifyChina factory:

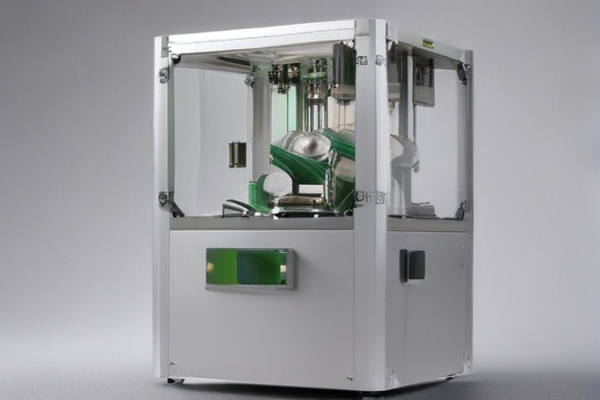

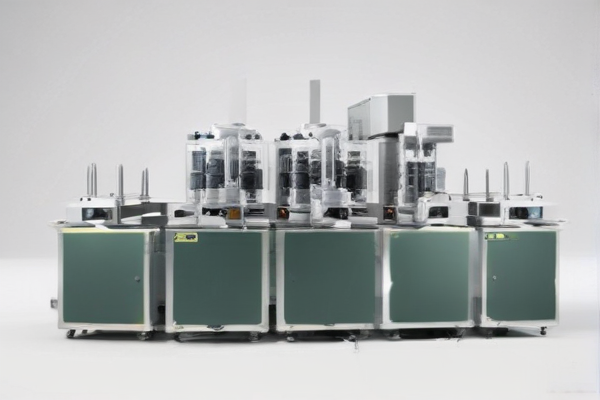

Q: What types of cannabis packaging machines does SourcifyChina offer?

A: SourcifyChina offers a variety of cannabis packaging machines, including filling machines, sealing machines, labeling machines, and automated packaging systems designed to handle different forms of cannabis products like flower, oils, and edibles.

Q: How does SourcifyChina ensure the quality of their cannabis packaging machines?

A: SourcifyChina ensures quality through stringent quality control processes, ISO certification, and using high-grade components. The factory also conducts thorough testing and inspections before delivery.

Q: Can SourcifyChina customize cannabis packaging machines to meet specific needs?

A: Yes, SourcifyChina offers customization options to meet specific requirements, including different machine sizes, capacities, and integration with existing production lines.

Q: What certifications do SourcifyChina cannabis packaging machines have?

A: SourcifyChina’s cannabis packaging machines are certified by international standards such as CE, ISO, and GMP, ensuring compliance with industry regulations and standards.

Q: What is the lead time for manufacturing and delivering a cannabis packaging machine?

A: The lead time typically ranges from 6 to 12 weeks, depending on the complexity and customization of the machine. SourcifyChina aims to provide timely updates throughout the production process.

Q: Does SourcifyChina provide after-sales support and training for their cannabis packaging machines?

A: Yes, SourcifyChina offers comprehensive after-sales support including technical assistance, training programs, and maintenance services to ensure optimal machine performance.

Q: How can I get a quotation or place an order with SourcifyChina?

A: You can get a quotation or place an order by contacting SourcifyChina directly through their website, email, or phone. Provide detailed requirements to receive a tailored quote promptly.

Q: Are SourcifyChina’s packaging machines energy-efficient?

A: Yes, SourcifyChina designs their machines to be energy-efficient, utilizing modern technology to minimize power consumption without compromising on performance.

Q: Is there a warranty on SourcifyChina’s cannabis packaging machines?

A: SourcifyChina offers a standard warranty period, generally ranging from one to two years, covering parts and labor. Extended warranties may also be available upon request.