Q: What types of capper machines does SourcifyChina factory offer?

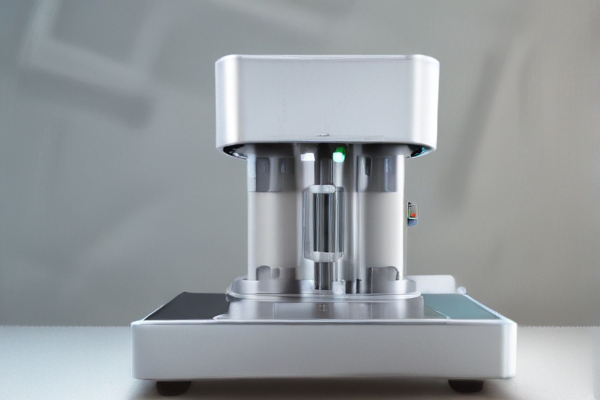

A: SourcifyChina offers a variety of capper machines, including semi-automatic, fully automatic, and rotary capper machines. They cater to various industries such as food and beverage, pharmaceuticals, and cosmetics.

Q: How can I get a quote for a capper machine from SourcifyChina?

A: To get a quote, you can visit the SourcifyChina website and fill out the inquiry form. Alternatively, you can contact their sales team directly via email or phone for personalized assistance.

Q: What are the lead times for sourcing a capper machine from SourcifyChina?

A: Lead times can vary depending on the machine type and customization requirements. Generally, it takes between 4 to 8 weeks from the order confirmation to delivery.

Q: Does SourcifyChina offer customization for capper machines?

A: Yes, SourcifyChina provides customization options to meet specific requirements, including machine size, speed, and compatibility with different cap types and sizes.

Q: What kind of after-sales support does SourcifyChina provide?

A: SourcifyChina offers comprehensive after-sales support including installation, training, and technical assistance. They also provide spare parts and maintenance services.

Q: Are there any warranties on the capper machines from SourcifyChina?

A: Yes, SourcifyChina offers a standard one-year warranty on all their capper machines, covering any manufacturing defects and providing free parts replacement during this period.

Q: How does SourcifyChina ensure the quality of their capper machines?

A: SourcifyChina conducts rigorous quality control processes, including pre-delivery inspections and performance testing, to ensure each machine meets international standards.

Q: Can I schedule a factory visit to SourcifyChina?

A: Yes, SourcifyChina welcomes factory visits. You can schedule an appointment by contacting their customer service team to arrange a suitable time.

Q: What payment methods are accepted by SourcifyChina?

A: SourcifyChina accepts various payment methods including wire transfers (T/T), letters of credit (L/C), and PayPal.

Q: Do SourcifyChina capper machines comply with international safety standards?

A: Yes, SourcifyChina capper machines comply with international safety standards such as CE and ISO certifications, ensuring high levels of safety and performance.