Sure, here are the frequently asked questions (FAQs) along with their answers for sourcing a capping bottle machine from SourcifyChina factory:

1. What types of capping bottle machines does SourcifyChina offer?

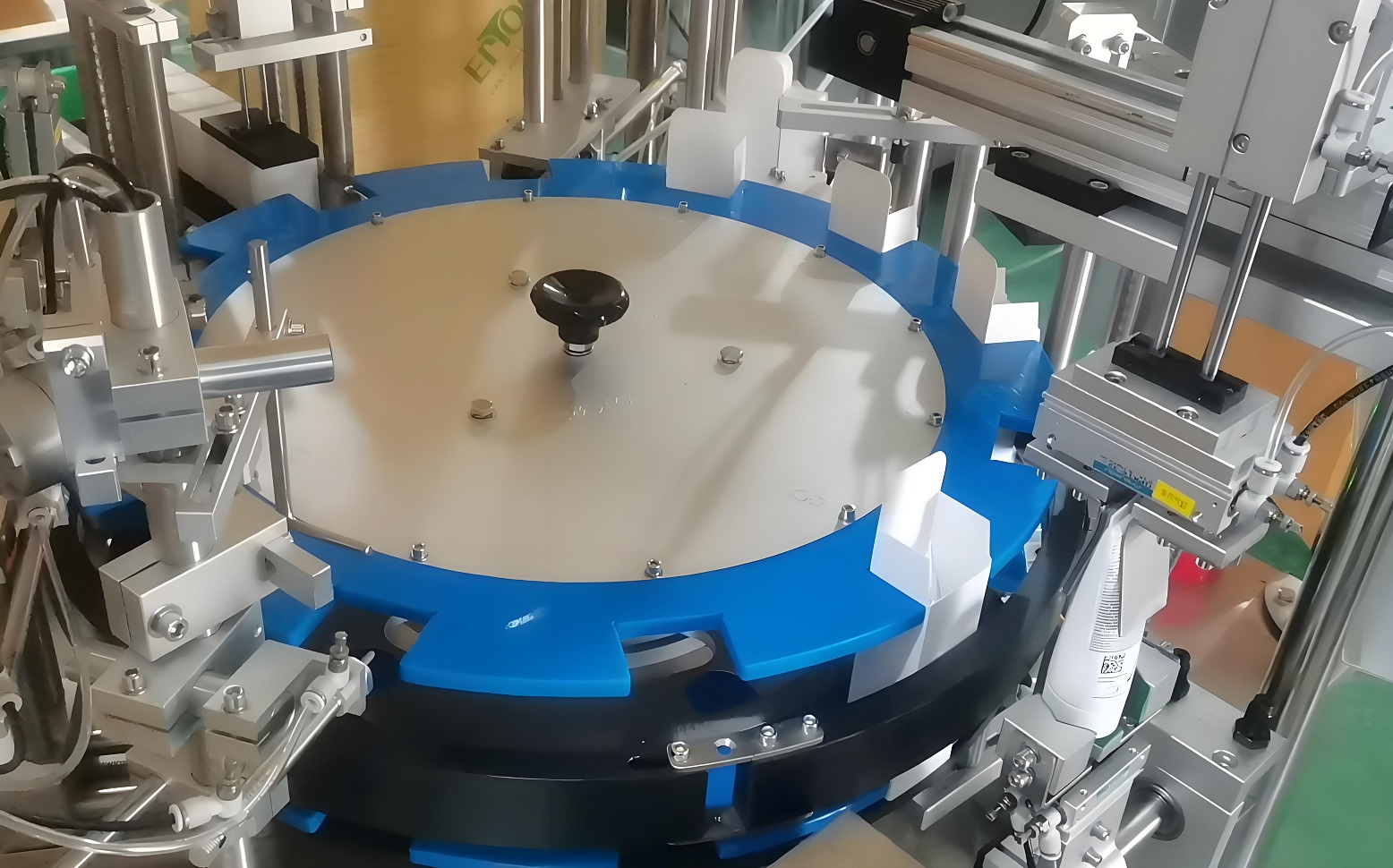

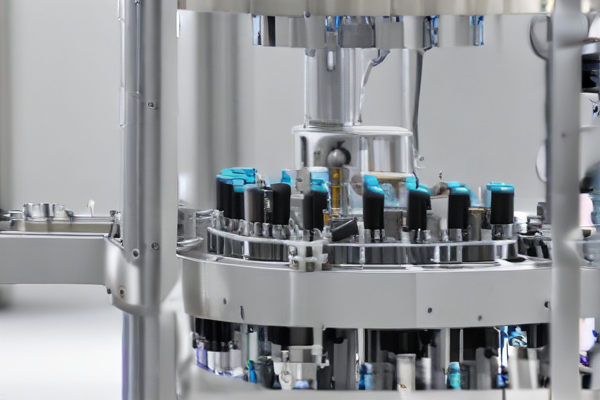

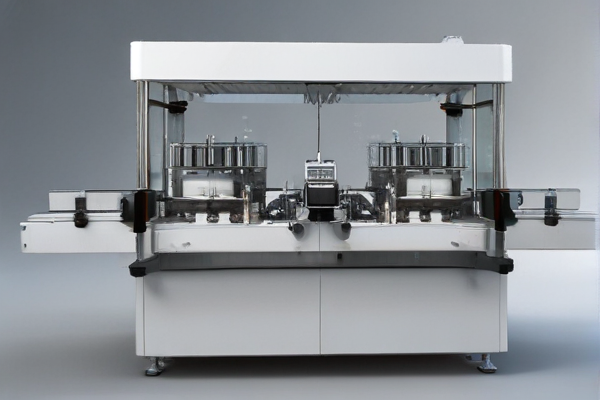

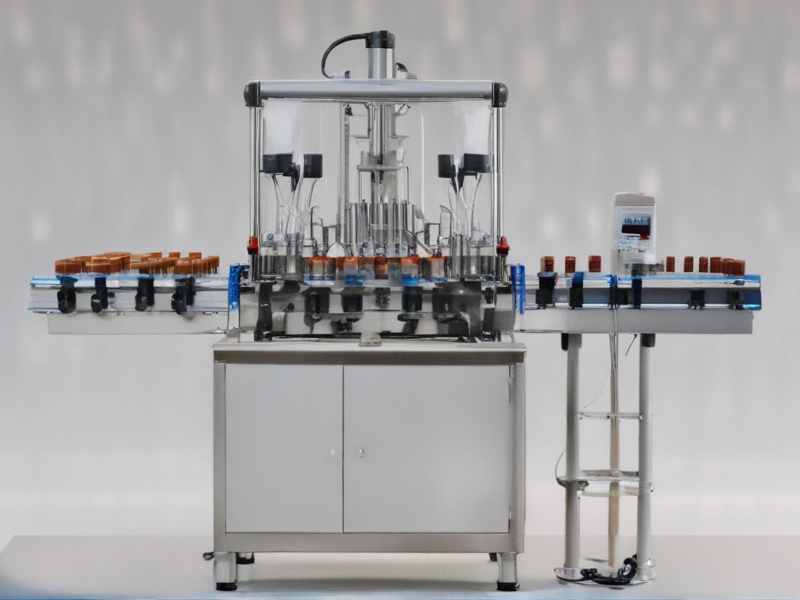

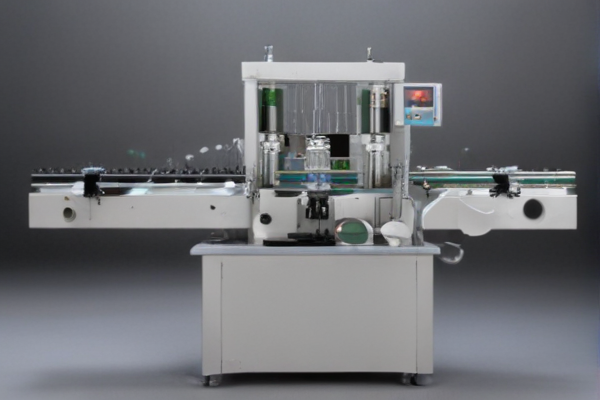

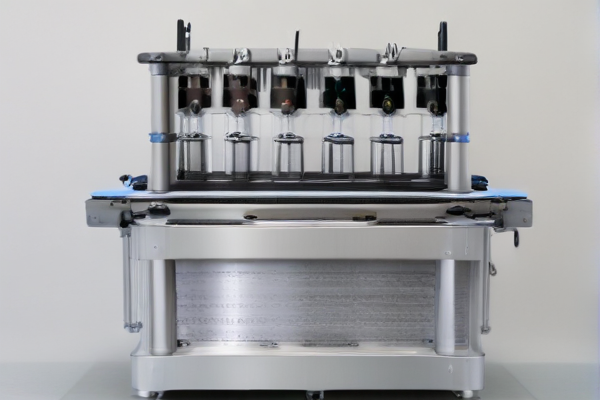

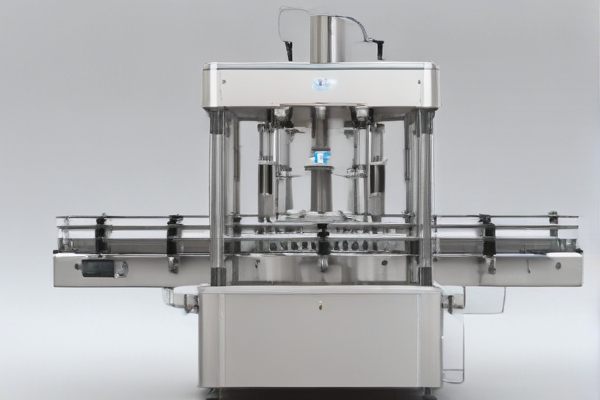

SourcifyChina provides a variety of capping bottle machines, including automatic, semi-automatic, and manual capping solutions suitable for different bottle sizes and cap types. Specific models cater to industries like pharmaceuticals, beverages, cosmetics, and more.

2. How can I get a quotation for a capping bottle machine?

To get a quotation, visit the SourcifyChina website and fill out the inquiry form with your specific requirements. Alternatively, you can contact them via email or phone, providing details such as the type of capping machine, production capacity, and any additional features you need.

3. What is the delivery time for a capping bottle machine?

Typically, the delivery time varies based on the order specifications and quantity. Standard models usually ship within 20-30 days, while customized machines might take longer. It’s best to confirm the estimated delivery time with the factory directly.

4. Do you offer after-sales service and technical support?

Yes, SourcifyChina provides comprehensive after-sales services, including installation, troubleshooting, maintenance, and technical support. They offer both remote and on-site assistance to ensure the smooth operation of your machine.

5. What payment methods are accepted?

SourcifyChina accepts various payment methods, including T/T (Telegraphic Transfer), L/C (Letter of Credit), and Western Union. Consult with their sales team to determine the most convenient option for your transaction.

6. Can I visit the factory to see the machines before purchasing?

Yes, you are welcome to visit the SourcifyChina factory to inspect their production facilities and see the machines in operation. Schedule an appointment with their sales team to arrange your visit.

7. Is customization available for the capping bottle machines?

Absolutely. SourcifyChina offers customization options to meet your specific needs, including custom designs, unique functionality, and specialized configurations. Provide detailed requirements for a tailored solution.

8. What kind of warranty is provided with the machines?

SourcifyChina typically offers a one-year warranty on their capping bottle machines. This covers manufacturing defects and ensures that any faulty parts are repaired or replaced within the warranty period.