Sure, here are some Frequently Asked Questions (FAQ) about capping machine quality work from SourcifyChina factory:

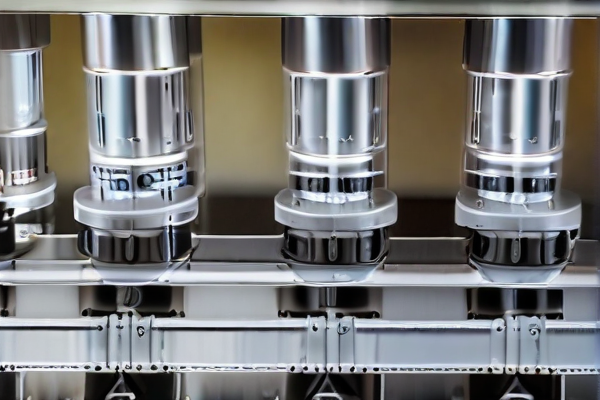

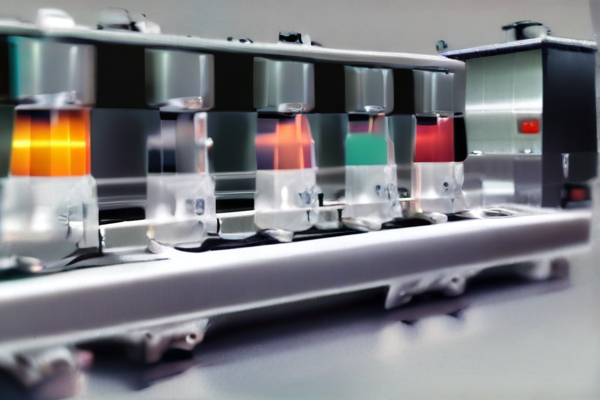

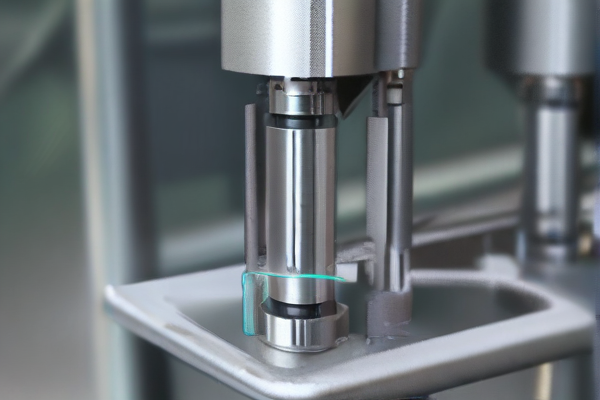

1. What types of capping machines do you manufacture?

SourcifyChina factory specializes in a variety of capping machines, including automatic, semi-automatic, and manual models suitable for different industries, such as pharmaceutical, food & beverage, and cosmetics.

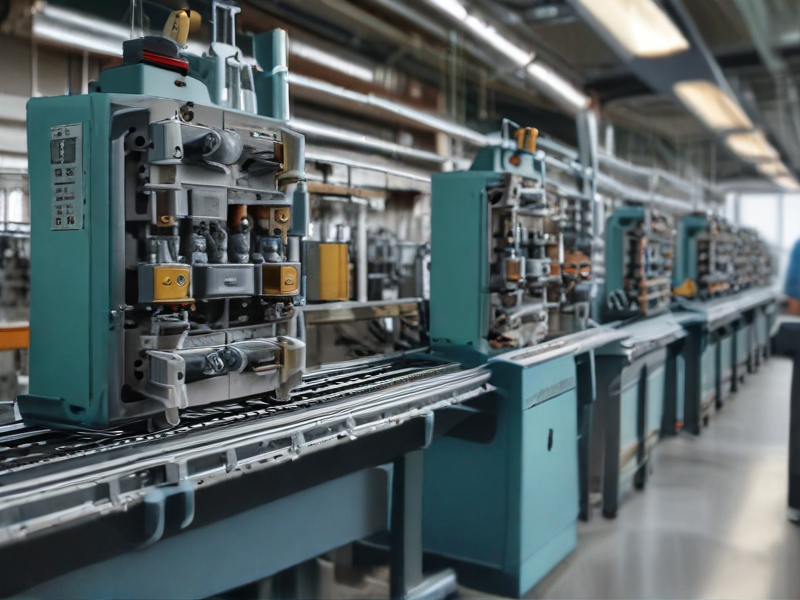

2. How do you ensure the quality of your capping machines?

We employ stringent quality control measures throughout our manufacturing process. This includes sourcing high-quality materials, conducting multiple inspections, and performing rigorous testing to ensure each machine meets industry standards.

3. Can your capping machines be customized?

Yes, we offer customization services to meet specific client requirements. Whether it’s adjusting machine dimensions, incorporating special features, or adapting to different cap types, our team works with you to create a tailored solution.

4. What is the lead time for manufacturing and delivery?

The typical lead time varies depending on the complexity and quantity of the order. Generally, it ranges from 4 to 8 weeks. We strive to deliver on or ahead of schedule and keep clients informed during the production process.

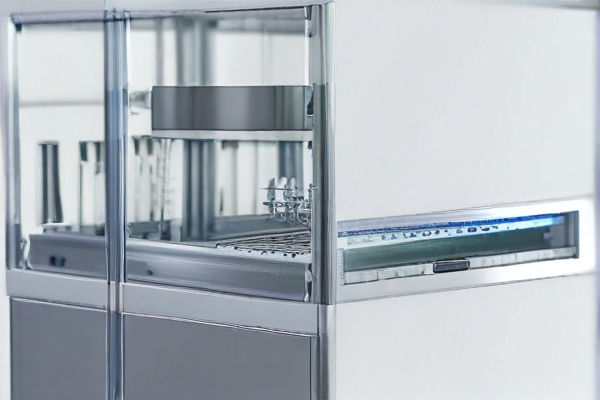

5. Do you provide after-sales support and training?

Absolutely. SourcifyChina provides comprehensive after-sales support, including troubleshooting, maintenance guides, and technical assistance. We also offer training sessions to ensure your team can operate the machinery efficiently.

6. What certifications do your capping machines have?

Our capping machines comply with international standards and carry certifications such as CE and ISO, assuring you of our commitment to quality and safety.

7. Can I visit your factory for a tour and inspection?

Yes, we welcome visits to our factory for tours and inspections. Contact us to schedule a visit and see our production process firsthand.

8. What are the payment terms?

Our standard payment terms are a 50% deposit upfront with the remaining 50% due before shipment. However, we are open to discussing alternative arrangements based on your needs.

9. How do I place an order?

To place an order, you can contact our sales team through our website, email, or phone. We will guide you through the process, answer any questions, and provide a detailed quotation.

10. Do you offer spare parts for your capping machines?

Yes, we provide a full range of spare parts to ensure the longevity and efficiency of your capping machines.