Frequently Asked Questions (FAQ) about Manufacturing Capping Machines Quality Work from SourcifyChina Factory

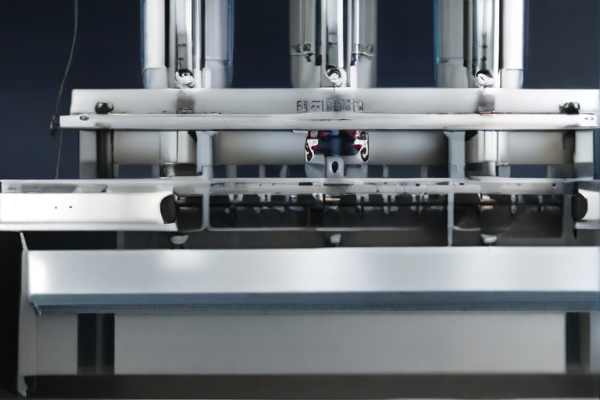

1. What types of capping machines does SourcifyChina manufacture?

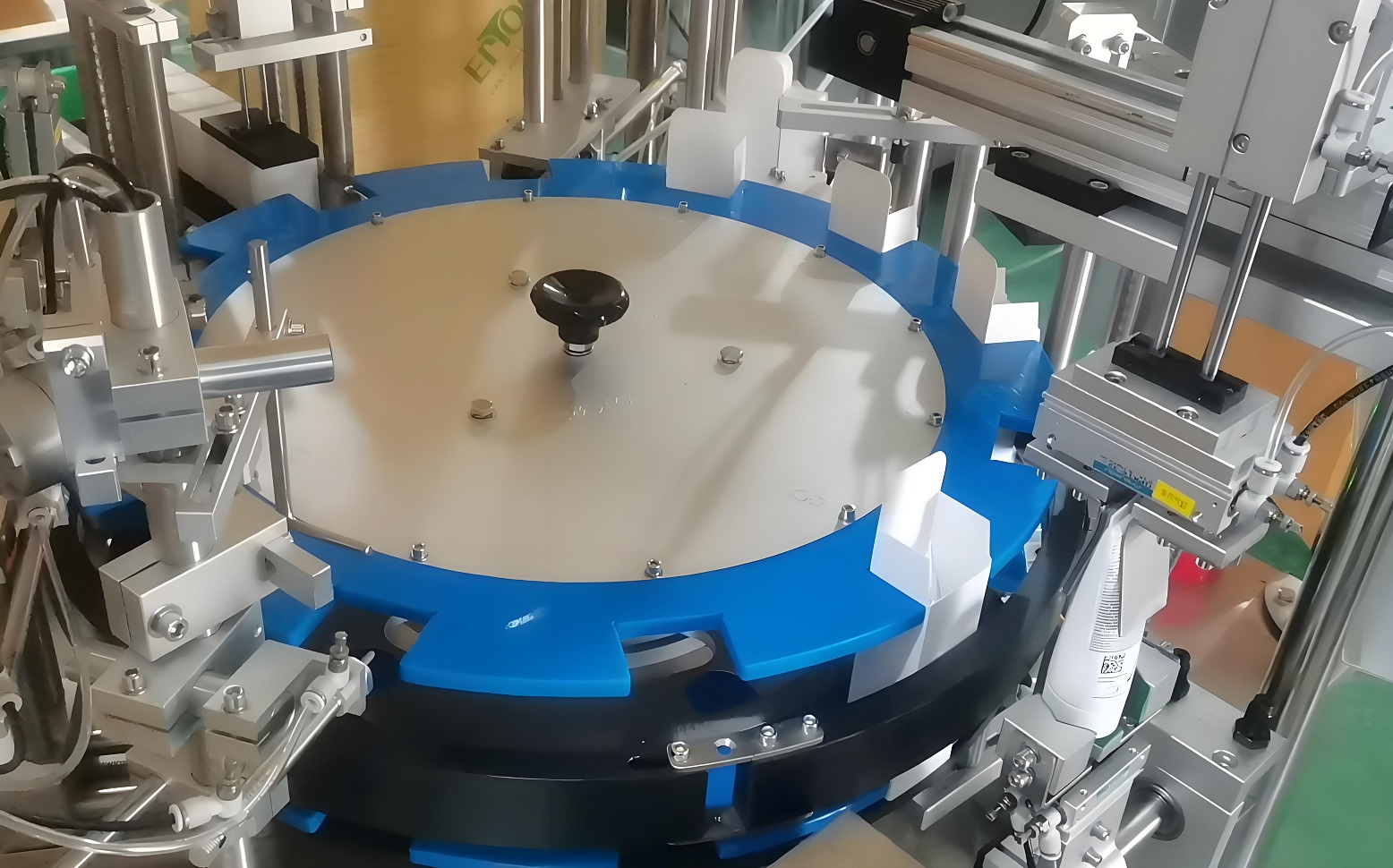

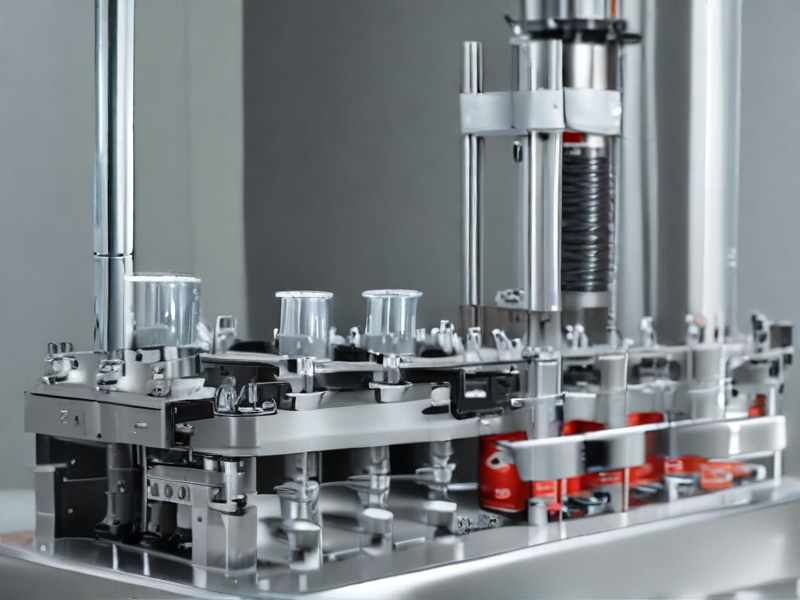

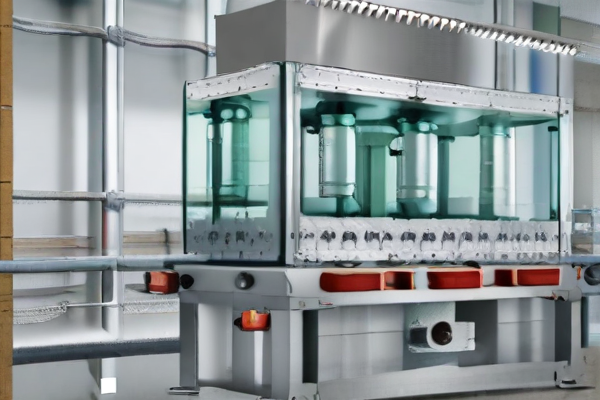

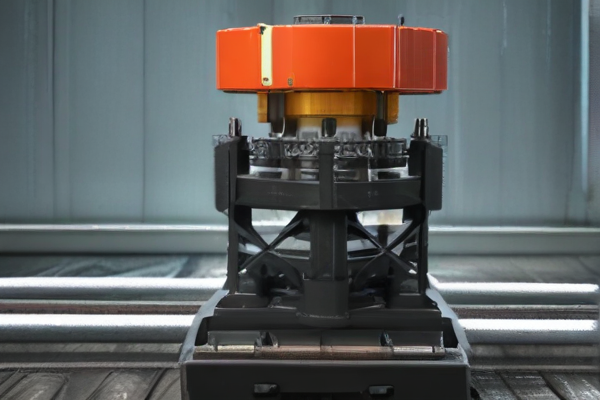

SourcifyChina manufactures various capping machines including automatic, semi-automatic, and manual capping machines tailored to different industries like pharmaceuticals, beverages, cosmetics, and more.

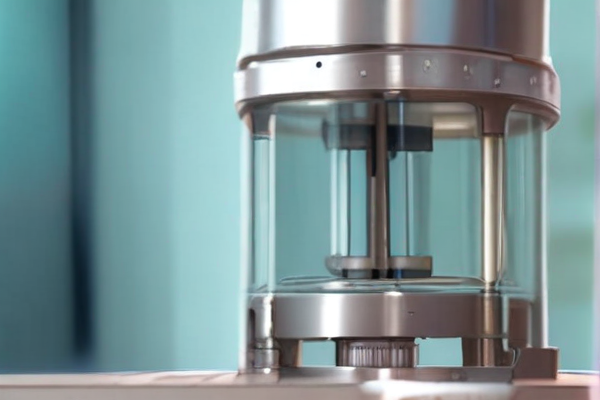

2. How does SourcifyChina ensure the quality of its capping machines?

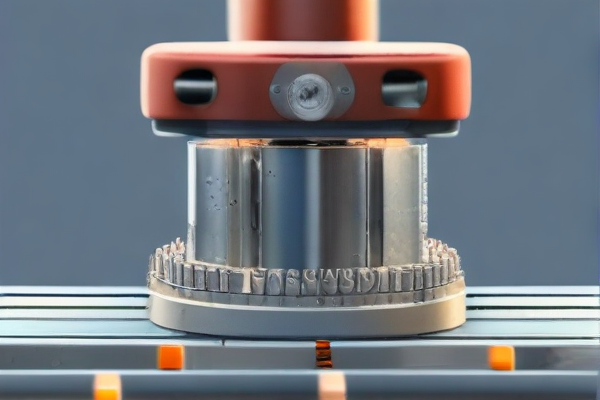

The factory employs strict quality control measures including material inspection, precision manufacturing techniques, and rigorous testing procedures to ensure each machine meets industry standards.

3. Are SourcifyChina’s capping machines customizable?

Yes, SourcifyChina offers customization options to fit specific production needs, including adjusting for different cap sizes, shapes, and production speeds.

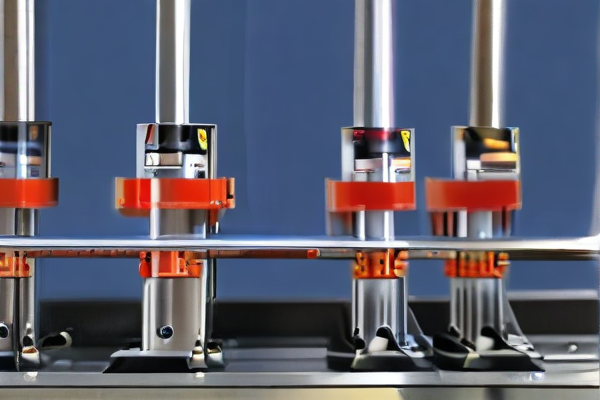

4. What materials are used in the construction of the capping machines?

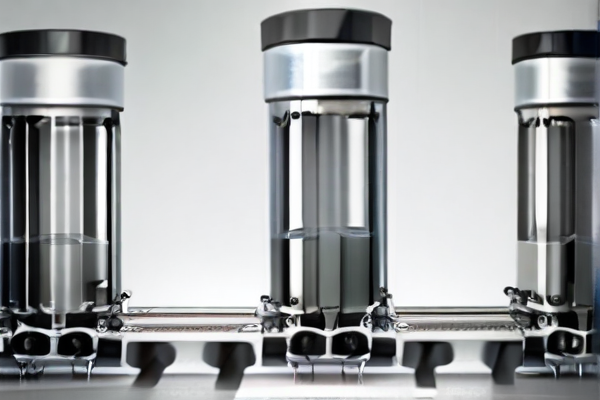

SourcifyChina uses high-quality materials such as stainless steel and durable polymers to ensure longevity and reliable performance in their capping machines.

5. Can SourcifyChina machines handle multiple types of caps and bottles?

Yes, the machines are designed to handle a variety of cap types and bottle sizes, making them versatile for different production lines.

6. What kind of after-sales support does SourcifyChina provide?

SourcifyChina offers comprehensive after-sales support, including installation assistance, maintenance services, and a warranty to address any potential issues.

7. How do I place an order for a capping machine from SourcifyChina?

Orders can be placed by contacting SourcifyChina’s sales team through their website or by calling their customer service hotline to discuss specific requirements.

8. What is the typical lead time for delivery of a capping machine?

The lead time varies depending on the machine type and customization, but typically ranges from 4 to 8 weeks from order confirmation to delivery.

9. Are training and setup included in the purchase?

Yes, SourcifyChina provides training and setup guidance to ensure seamless integration into your production line.

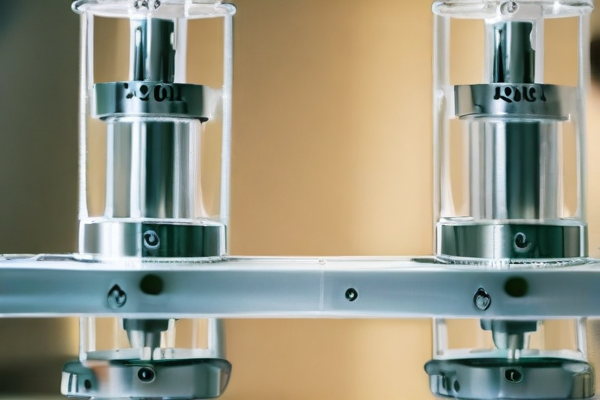

10. How energy-efficient are SourcifyChina’s capping machines?

Designed with energy efficiency in mind, SourcifyChina’s capping machines incorporate advanced technology to minimize power consumption while maintaining high performance.