Here are some frequently asked questions (FAQ) about sourcing capping systems from SourcifyChina factory:

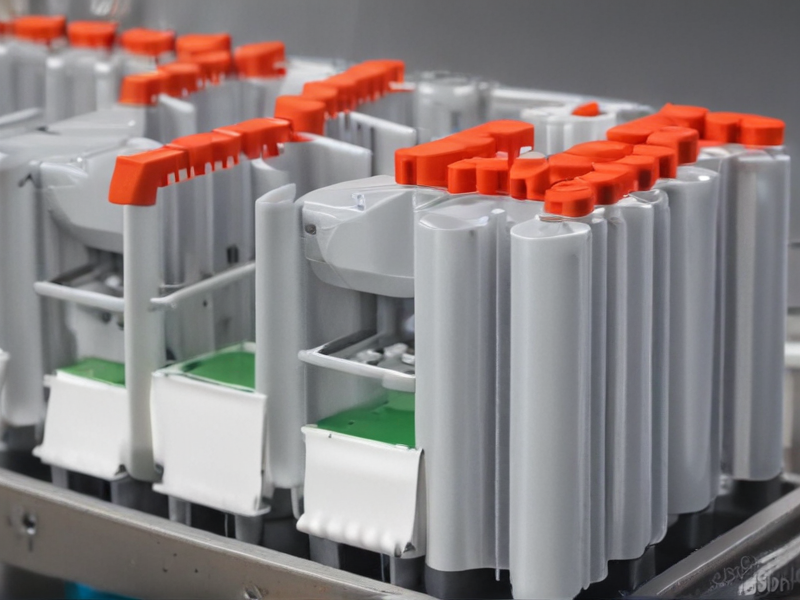

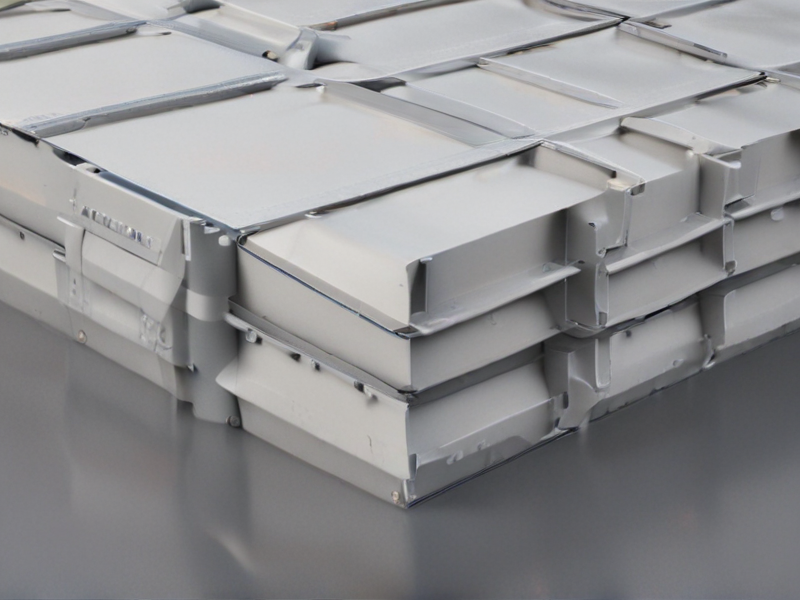

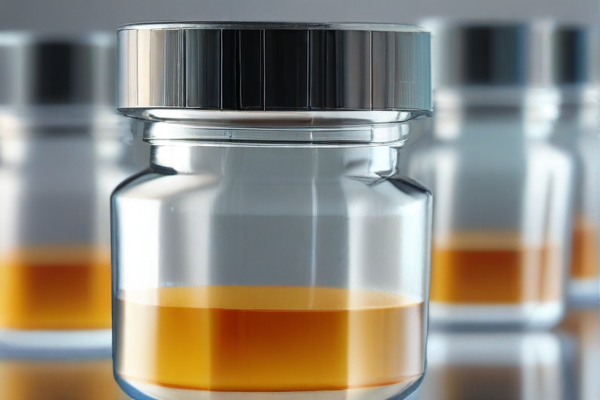

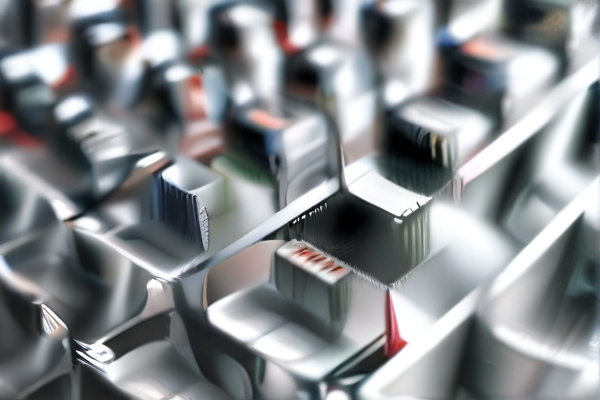

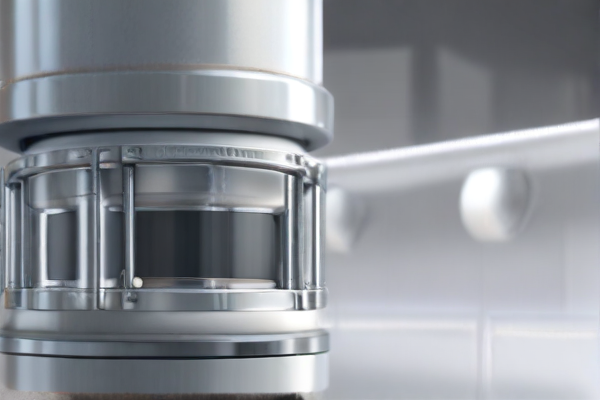

1. What types of capping systems do you offer?

SourcifyChina offers a wide range of capping systems, including manual, semi-automatic, and fully automatic machines suitable for different industries such as food and beverage, pharmaceuticals, cosmetics, and more.

2. How can I place an order with SourcifyChina?

You can place an order by contacting us through our website, email, or phone. Our customer service team will guide you through the process, including product selection, customization options, and order confirmation.

3. Do you provide customization for capping systems?

Yes, we offer customization according to your specific requirements. You can discuss your needs with our technical team, and we will work to provide a tailored solution that fits your production line.

4. What are the payment terms?

We accept various payment methods including T/T, L/C, and Western Union. Specific terms can be discussed during the order confirmation process.

5. Can I get a sample or a demonstration of the capping systems?

Yes, samples and demonstrations can be arranged. Please contact our customer service team to schedule a demonstration or request a sample unit.

6. How long does delivery take?

Delivery time varies depending on the type of capping system and customization requirements. Typically, it takes around 4-6 weeks for production and shipment. We will provide an estimated delivery time once your order is confirmed.

7. What kind of after-sales service do you provide?

We offer comprehensive after-sales services including installation support, training, maintenance, and online technical assistance to ensure your capping system operates smoothly.

8. What is the warranty period for your capping systems?

Our capping systems come with a standard one-year warranty, which covers defects in materials and workmanship. Extended warranty options are also available upon request.

9. Are your capping systems compliant with international standards?

Yes, our capping systems are designed and manufactured in compliance with international standards to ensure high quality and reliability.

10. How do I get in touch with SourcifyChina for more information?

You can reach us through our official website contact form, email, or by phone. Our customer support team is available to answer any further questions and provide the information you need.