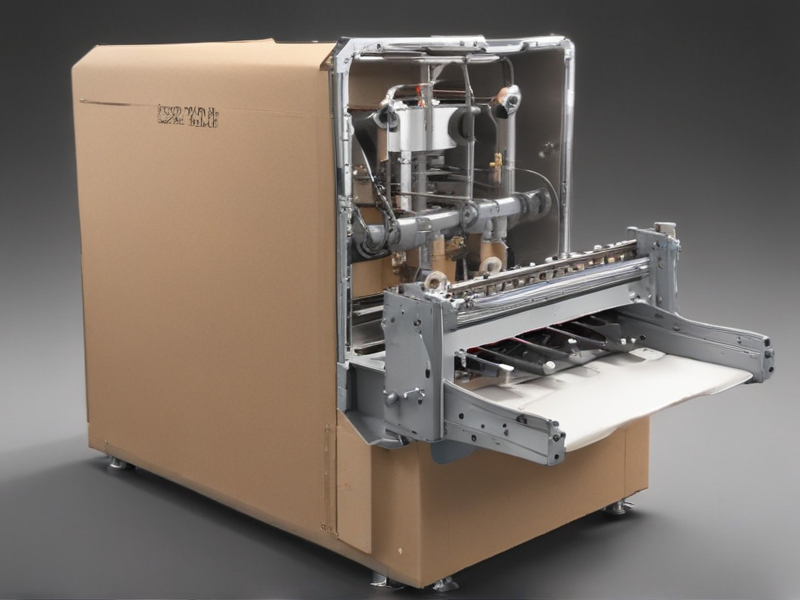

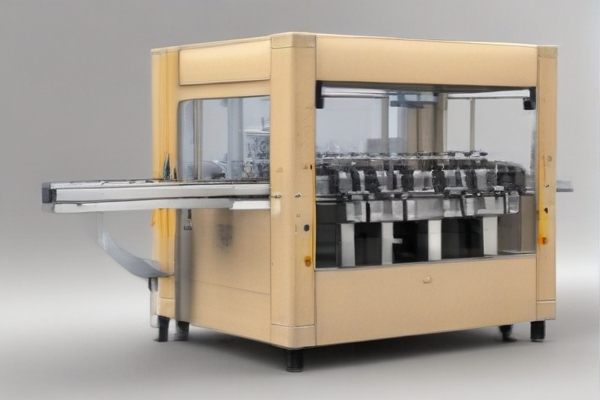

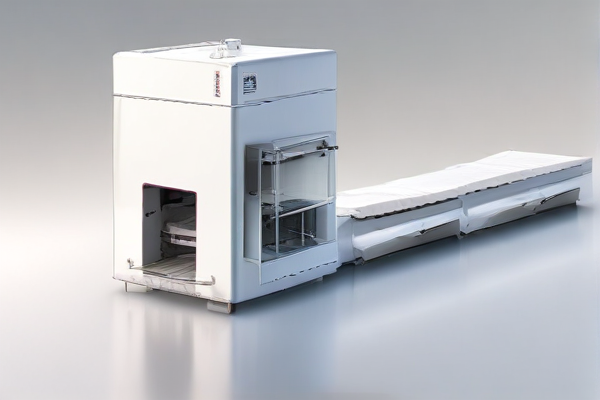

A carton packaging machine automates the process of forming, filling, and sealing cartons, ensuring efficient and consistent packaging for various industries.

– Food and Beverage: Streamline packaging for products like cereals, milk, and snacks.

– Pharmaceuticals: Secure and hygienic packaging for medicines and supplements.

– Consumer Goods: Convenient packaging for items such as toothpaste, cosmetics, and electronics.

– E-commerce: Rapid and reliable packaging of products for online deliveries.

– Retail: Attractive and protective packaging for merchandising.

– Industrial Products: Packaging for tools, hardware, and electrical components.

– Agriculture: Efficient packaging for seeds, fertilizers, and other agro-products.

– Luxury Items: High-quality packaging for perfumes, watches, and jewelry.

– Automotive: Safe packaging for parts and accessories.

– Healthcare: Hygienic packaging for medical supplies and devices.

– Frozen Foods: Secure and tamper-evident packaging for frozen meals and desserts.

– Dry Goods: Efficient packaging for grains, pasta, and other non-perishables.

– Flexible Packaging Solutions: Customizable options for various product sizes and shapes.

– Sustainable Packaging: Use of eco-friendly materials for environmentally conscious companies.

– Brand Promotion: Enhances brand image with high-quality, well-designed packaging.

– Reduction of Labor Costs: Automation reduces the need for manual labor.

– Improved Product Safety: Ensures products are securely sealed and protected.

– Increased Production Rate: Expedites the packaging process, boosting productivity.

– Cost Efficiency: Minimizes waste and optimizes materials usage.

– Compliance: Meets industry standards and regulatory requirements.

– Versatility: Suitable for a wide range of products and industries.

– Traceability: Enables batch and date coding for quality control and tracking.

– Customization: Adaptable to different packaging designs and sizes.

– Reduced Errors: Ensures consistent and precise packaging, minimizing errors.

– Space Efficiency: Compact designs for space-constrained facilities.

– Durability: Robust machinery designed for long-term use.

– User-friendly Operation: Intuitive interfaces for easy operation and maintenance.