Sourcing a case erector machine from SourcifyChina Factory can streamline your packaging operations and potentially save costs. Here are some tips to ensure a smooth process:

1. Research and Identify Needs:

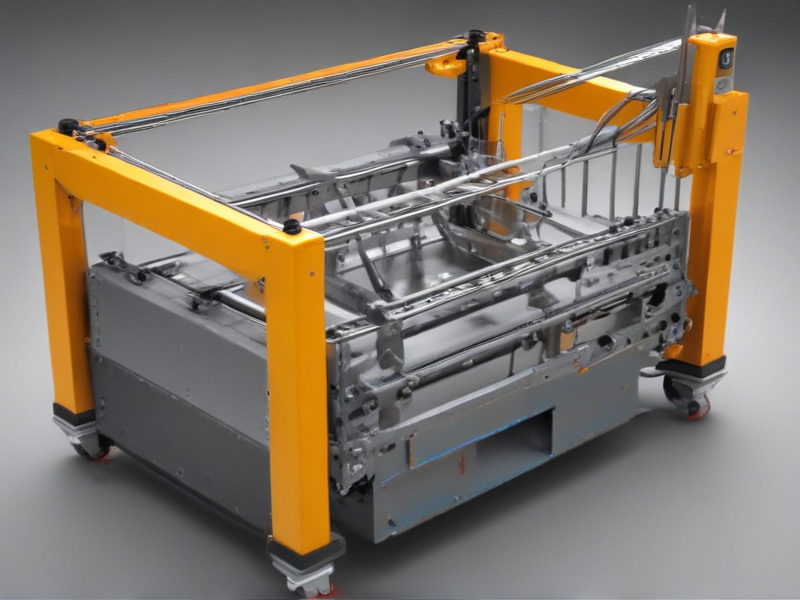

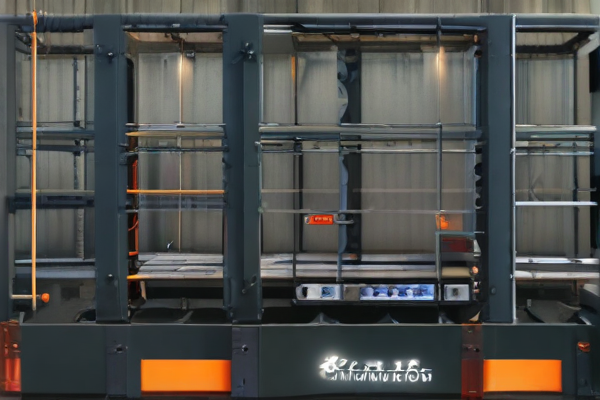

– Determine your specific requirements such as machine size, speed, and technological features.

– Look for case erectors suitable for the types and sizes of boxes you’ll be using.

2. Contact SourcifyChina:

– Reach out through their official website or authorized platforms.

– Use clear and precise language to communicate your needs.

3. Verify Factory Credentials:

– Ask for certifications, quality control processes, and previous client references.

– Check for compliance with international standards.

4. Request Detailed Quotations:

– Ask for a comprehensive quote including shipping, installation, and any taxes.

– Clarify warranty terms and after-sales support.

5. Assess Quality and Reliability:

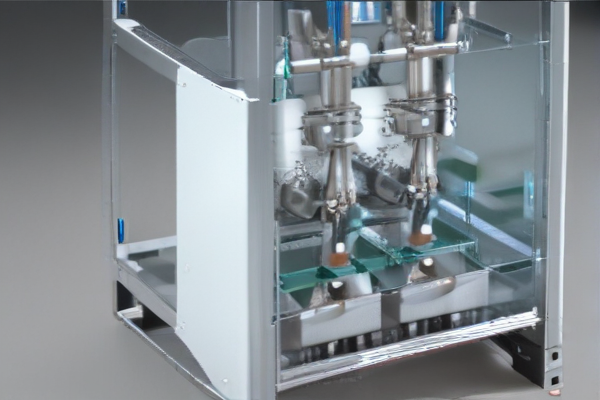

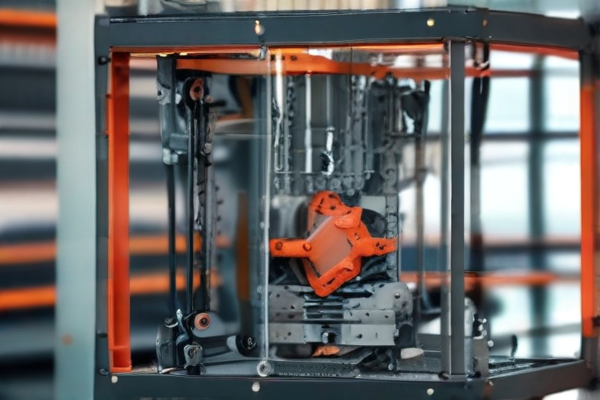

– If possible, request a video demonstration of the machine in operation.

– Inquire about the materials used in construction to ensure durability.

6. Negotiate Terms:

– Discuss payment terms, delivery timelines, and potential discounts for bulk orders.

– Ensure contract terms are clear on both sides.

7. Sample Order:

– Consider ordering a sample unit to test its compatibility with your operations before committing to a large purchase.

8. Logistics:

– Plan for freight, customs clearance, and local transport.

– Work with a reliable logistics partner to avoid delays.

9. Legal and Compliance:

– Verify the machine meets safety regulations in your country.

– Ensure you have all necessary import/export documentation.

10. Build Relationship:

– Maintain good communication and establish a long-term relationship with the supplier for future needs.

By following these steps, you can effectively source a case erector machine from SourcifyChina Factory that meets your business requirements.