Sure, here’s a concise FAQ list for sourcing a chemical packaging machine from SourcifyChina factory:

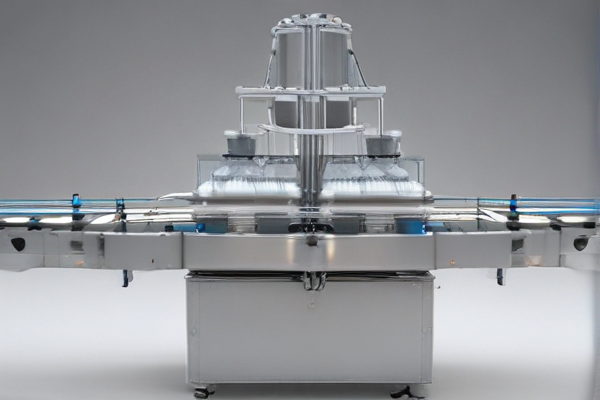

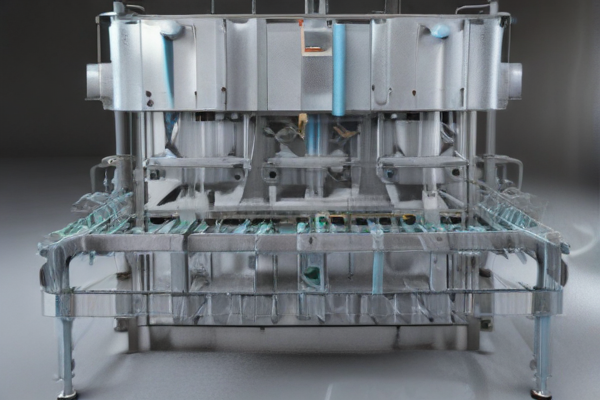

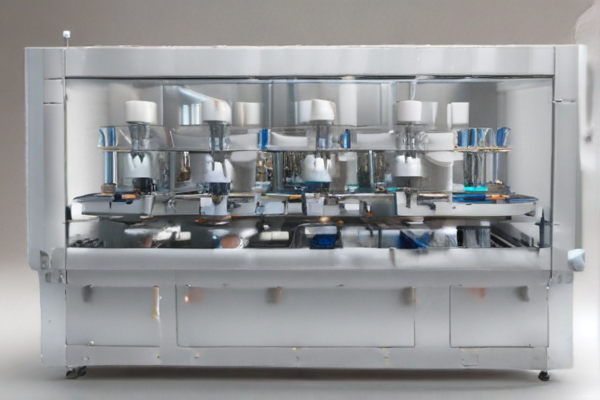

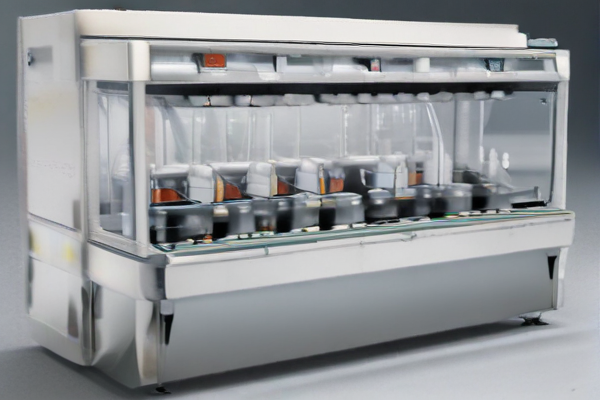

1. What types of chemical packaging machines does SourcifyChina offer?

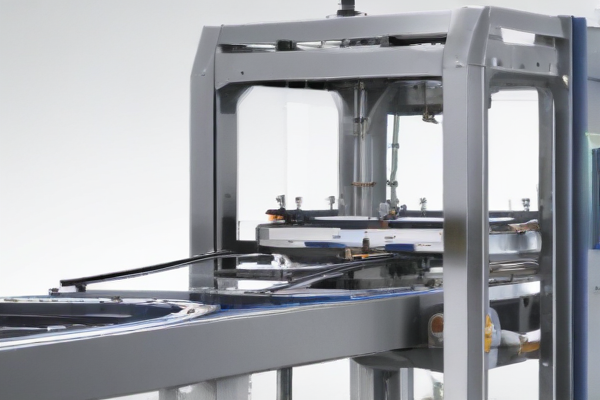

SourcifyChina offers a diverse range of chemical packaging machines, including liquid fillers, powder packagers, granule packagers, and sealing machines. Custom solutions are also available to meet specific requirements.

2. Are the machines compliant with international safety standards?

Yes, all machines from SourcifyChina are designed and manufactured to comply with international safety standards, including CE and ISO certifications.

3. Can I get customization for my packaging machine?

Absolutely. SourcifyChina provides comprehensive customization options to meet the unique needs of your production line and product specifications.

4. What is the lead time for machine delivery?

The lead time typically ranges from 4 to 8 weeks, depending on the complexity of customization and current order backlog.

5. How do I ensure the quality of the machine before purchasing?

SourcifyChina offers detailed product specifications, video demonstrations, and sample tests. You can also request an on-site inspection or third-party inspection services.

6. What is the warranty period for the machines?

The machines come with a standard one-year warranty covering manufacturing defects. Extended warranty options are available upon request.

7. How is after-sales support managed?

After-sales support includes remote troubleshooting, spare parts supply, and on-site service if necessary. A dedicated support team is available to assist you.

8. What are the payment terms?

Payment terms typically include a 30% deposit upon order confirmation and the remaining 70% before shipment. SourcifyChina accepts payments via T/T, L/C, and other secure methods.

9. Can I visit the factory before making a decision?

Yes, SourcifyChina welcomes factory visits. You can schedule a visit to inspect the facilities and meet the team to discuss your requirements in detail.

10. How do I get a quote for a chemical packaging machine?

You can get a quote by filling out the online inquiry form on SourcifyChina’s website or contacting their sales team directly via email or phone with your specific requirements.