Certainly! Here are some frequently asked questions (FAQ) regarding the quality of coating machines manufactured by SourcifyChina factory:

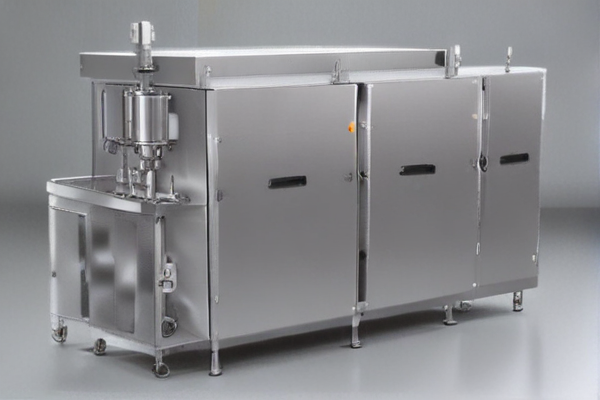

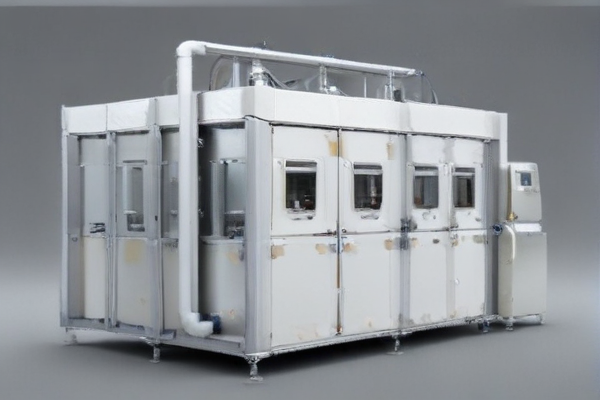

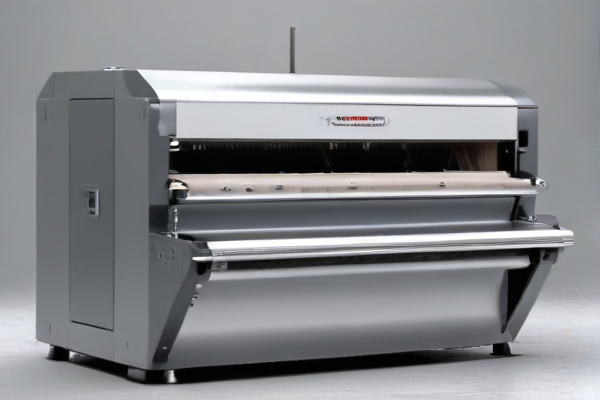

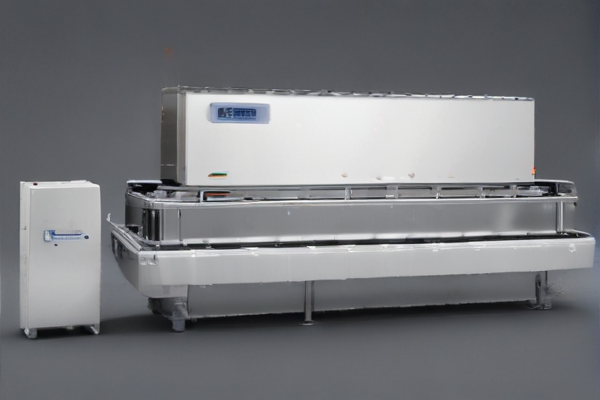

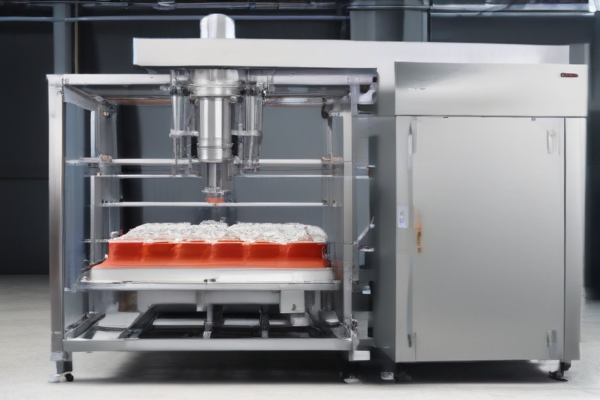

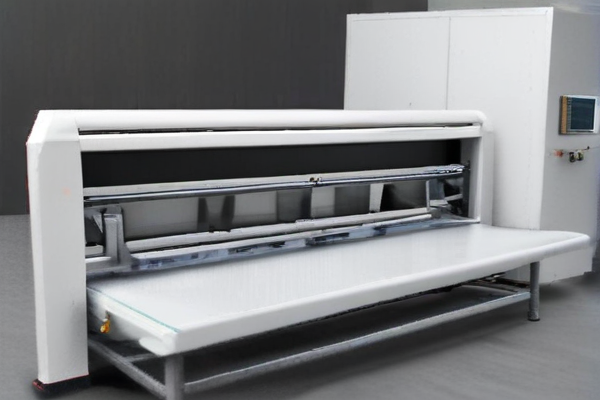

Q1: What types of coating machines does SourcifyChina manufacture?

A1: SourcifyChina specializes in a wide range of coating machines, including but not limited to, spray coating machines, dip coating machines, and powder coating machines.

Q2: How does SourcifyChina ensure the quality of its coating machines?

A2: SourcifyChina ensures quality through rigorous testing, adherence to international standards, and extensive quality control checks at every manufacturing stage.

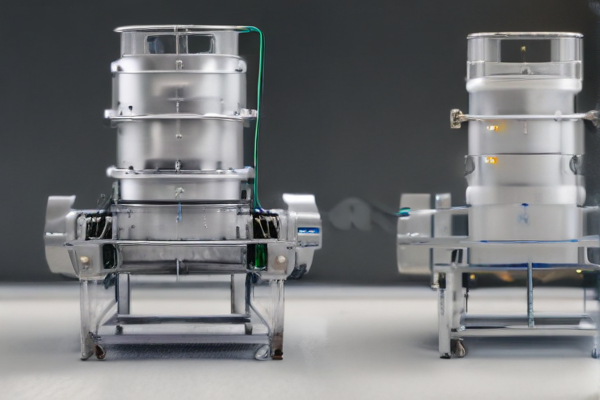

Q3: Are the coating machines customizable?

A3: Yes, SourcifyChina provides customization options to meet specific requirements of clients, including machine dimensions, coating material compatibility, and automation levels.

Q4: What materials are the coating machines compatible with?

A4: SourcifyChina’s coating machines are designed to handle a variety of materials such as metals, plastics, ceramics, and composites.

Q5: What is the lead time for manufacturing and delivery?

A5: The lead time typically ranges from 8 to 12 weeks, depending on the complexity and customization of the machine. This includes production, quality testing, and shipping.

Q6: Do the coating machines come with a warranty?

A6: Yes, all coating machines from SourcifyChina come with a standard one-year warranty that covers defects and malfunctions due to manufacturing faults.

Q7: Is technical support available after purchase?

A7: SourcifyChina provides comprehensive after-sales service, including technical support, maintenance guidance, and access to spare parts.

Q8: Can I visit the SourcifyChina factory for inspection?

A8: Yes, clients are welcome to visit the factory for inspection. An appointment can be scheduled through their customer service team.

Q9: Are the machines eco-friendly?

A9: SourcifyChina is committed to sustainable manufacturing. Their coating machines are designed to minimize waste, improve energy efficiency, and comply with environmental regulations.

Q10: How can I place an order?

A10: Orders can be placed directly through the SourcifyChina website or by contacting their sales team via email or phone for detailed assistance.

These answers provide essential insights into the quality and service offered by SourcifyChina for their coating machines.