Q: What types of coffee packaging machinery does SourcifyChina factory manufacture?

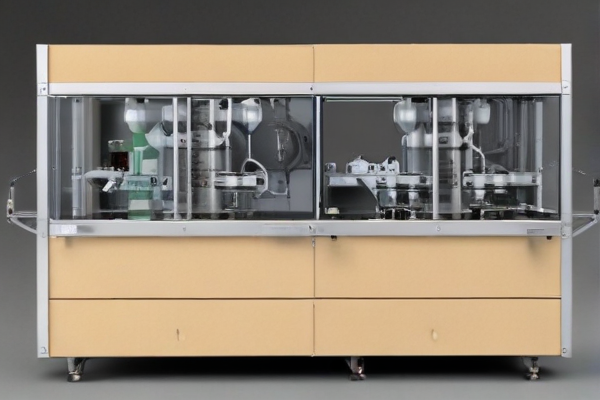

A: SourcifyChina factory specializes in a variety of coffee packaging machinery including vacuum packaging machines, pouch filling and sealing machines, vertical and horizontal form fill seal machines, and custom packaging solutions tailored to client needs.

Q: What quality standards does SourcifyChina adhere to in manufacturing machinery?

A: SourcifyChina follows stringent quality control processes and adheres to international standards such as ISO 9001, CE (Conformité Européenne), and GMP (Good Manufacturing Practice) to ensure high-quality and reliable machinery.

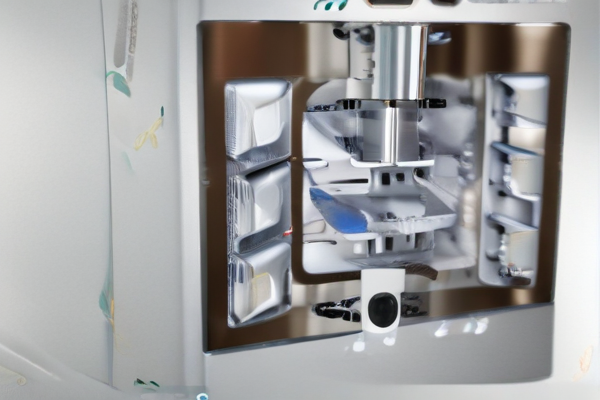

Q: What materials are used in the construction of SourcifyChina’s coffee packaging machines?

A: High-grade stainless steel is predominantly used for durability, hygiene, and to prevent oxidation and corrosion. Other quality components include FDA-approved food-grade plastics.

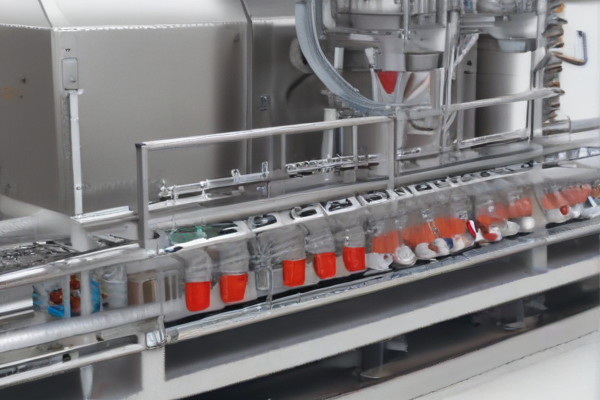

Q: Do the machines support different types of coffee packaging formats?

A: Yes, the machines are versatile and can handle various packaging formats such as pouches, sachets, bags, and vacuum packs, suitable for ground coffee, coffee beans, and instant coffee.

Q: How can I verify the quality of the coffee packaging machinery before purchasing?

A: Clients can request product demonstrations, visit the factory for on-site inspections, and review third-party quality certifications. SourcifyChina also offers sample testing and trial runs.

Q: What after-sales services does SourcifyChina provide?

A: SourcifyChina offers comprehensive after-sales support including installation services, operational training, remote technical assistance, spare parts supply, and maintenance services.

Q: Can the machinery be customized according to my specific requirements?

A: Yes, SourcifyChina provides customization options to meet specific requirements related to size, speed, packaging format, and other special features. Clients can discuss their needs directly with the engineering team.

Q: What is the typical lead time for manufacturing and delivery?

A: The lead time varies depending on the complexity of the machinery and customizations required, but generally ranges from 4 to 12 weeks from order confirmation to delivery.

Q: How does SourcifyChina ensure equipment durability and longevity?

A: By using high-quality materials, state-of-the-art manufacturing techniques, and rigorous testing, SourcifyChina ensures that its coffee packaging machinery is durable and built to deliver long-term performance.

Q: Are there any warranties provided on the coffee packaging machinery?