Sure, here are some frequently asked questions (FAQ) regarding the quality of coffee packing machines manufactured by SourcifyChina factory:

Q1: What types of coffee packing machines does SourcifyChina manufacture?

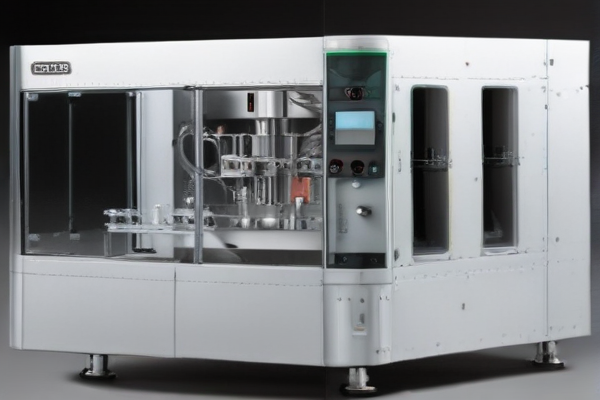

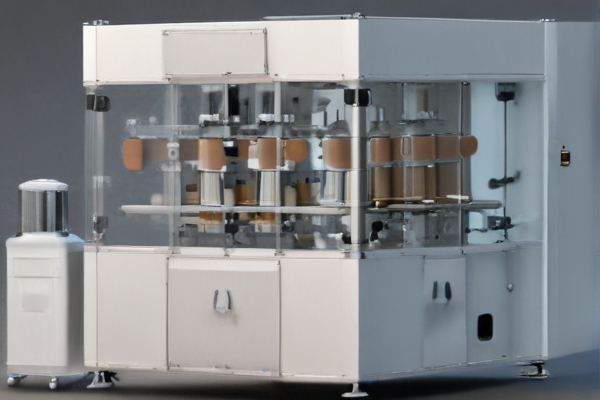

A1: SourcifyChina manufactures a range of coffee packing machines including automatic, semi-automatic, vacuum packing, and vertical form fill seal (VFFS) machines to cater to various packaging needs.

Q2: How does SourcifyChina ensure the quality of its coffee packing machines?

A2: SourcifyChina ensures quality by following strict ISO certification standards, using high-quality materials, and employing advanced technology. Each machine undergoes rigorous testing and quality control checks before dispatch.

Q3: Can the machines handle different packaging materials?

A3: Yes, SourcifyChina’s machines are designed to handle a variety of packaging materials, including plastic, aluminum foil, and laminated films, allowing for flexibility in packaging options.

Q4: Are the machines customizable according to specific requirements?

A4: Absolutely, SourcifyChina offers customization options to meet specific client needs, including different machine sizes, sealing methods, and additional features like printers and labelers.

Q5: What is the delivery time for a coffee packing machine from SourcifyChina?

A5: The standard delivery time is typically 4-6 weeks, depending on the level of customization and order quantity. SourcifyChina aims to manage timely deliveries without compromising on quality.

Q6: Does SourcifyChina provide after-sales support and service?

A6: Yes, SourcifyChina offers comprehensive after-sales support, including installation guidance, training, maintenance services, and availability of spare parts to ensure optimal machine performance.

Q7: Are there any guarantees or warranties offered with the machines?

A7: SourcifyChina provides a one-year warranty covering manufacturing defects and offers extended warranty options. Regular maintenance and proper usage can enhance machine longevity.

Q8: How energy-efficient are SourcifyChina’s coffee packing machines?

A8: SourcifyChina designs its machines with energy efficiency in mind, utilizing advanced technology to minimize power consumption while maximizing performance.

Q9: What are the safety features of the coffee packing machines?

A9: The machines are equipped with multiple safety features including emergency stop buttons, overload protection, and user-friendly interfaces to ensure operator safety.

Q10: Can SourcifyChina handle bulk orders for large-scale operations?