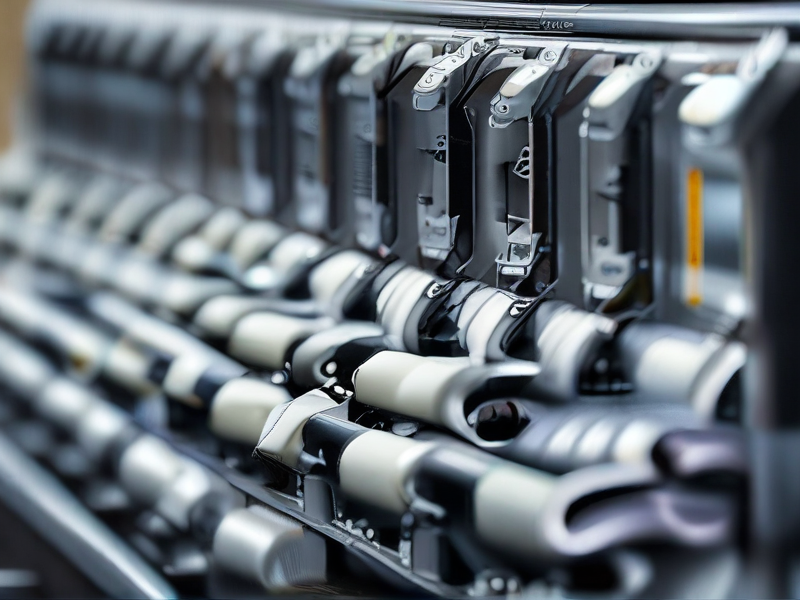

What is a collating machine?

A collating machine is an industrial device used to gather and arrange pages or documents in a pre-specified order. It is commonly used in printing and binding industries to ensure the correct sequence of pages in books, flyers, manuals, etc.

Why choose SourcifyChina factory for collating machines?

SourcifyChina factory is renowned for its high-quality manufacturing standards, advanced technology, and excellent customer service. They offer reliable and durable collating machines tailored to meet specific industry needs.

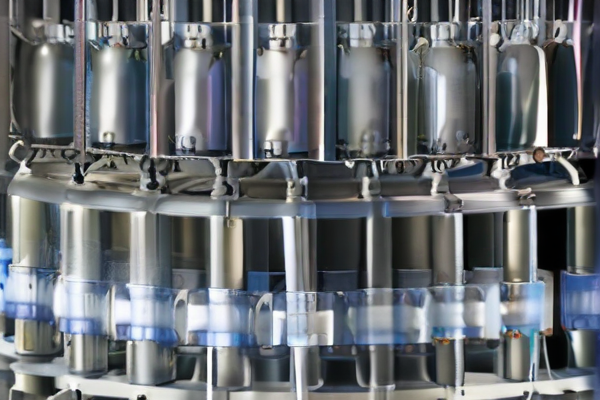

What types of collating machines are available at SourcifyChina factory?

SourcifyChina factory offers a variety of collating machines including inline, offline, and digital collators. Each type caters to different production capacities and operational requirements.

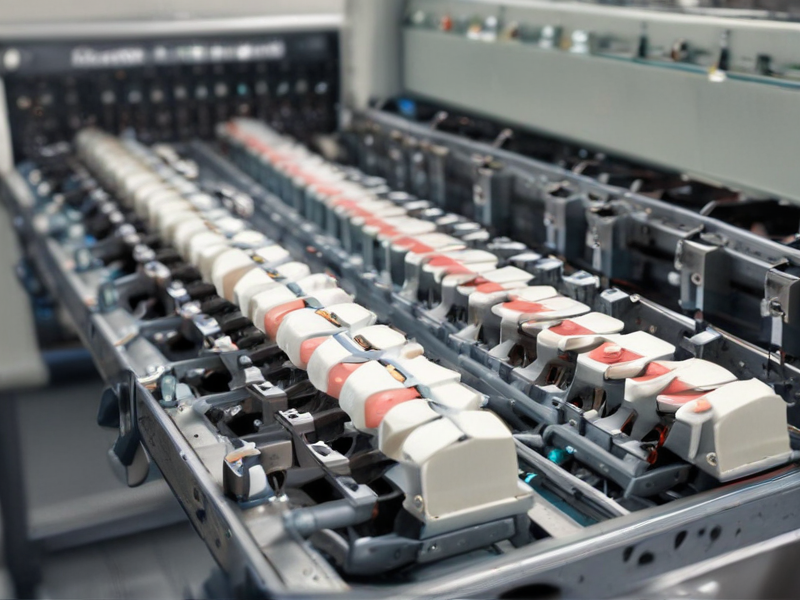

How can I ensure the quality of the collating machine from SourcifyChina factory?

SourcifyChina factory follows stringent quality control practices, including raw material inspection, in-process inspections, and final testing. They also offer certifications and warranties to ensure you receive a quality product.

What is the lead time for a collating machine order?

Lead times may vary based on the model and customization requirements. Typically, the production and delivery process can take between 4 to 8 weeks.

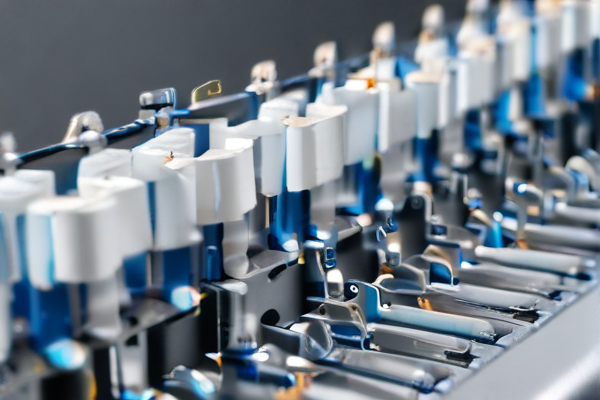

Can I customize the collating machine according to my requirements?

Yes, SourcifyChina factory offers customization options to fit your specific needs, including adjustments in machine size, speed, and additional functionalities.

What kind of support and services does SourcifyChina provide post-purchase?

SourcifyChina factory provides comprehensive post-purchase support, including installation, training, maintenance, and troubleshooting services to ensure smooth operation of the machine.

Are there any testimonials or reviews I can refer to?

Yes, SourcifyChina factory features customer testimonials and case studies on their website. You can also request references from past clients to gauge satisfaction and product reliability.

What are the payment terms for purchasing a collating machine?

Payment terms typically include a deposit upon order confirmation and the remaining balance before shipment. SourcifyChina factory is flexible and may offer different payment options depending on the order size and client relationship.

How do I start the ordering process?

To start the ordering process, you can contact SourcifyChina factory directly through their website or customer service hotline. They will guide you through product selection, customization options, and formalize your order with a quote.