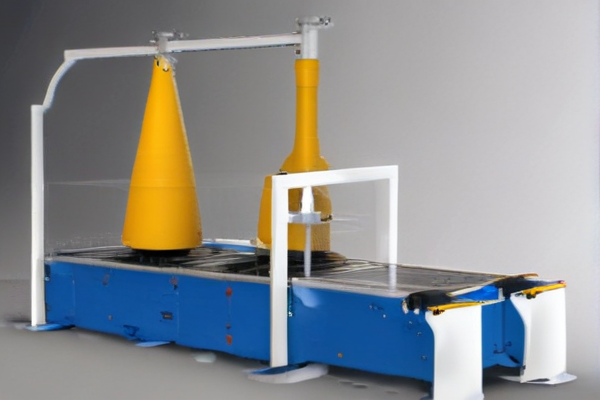

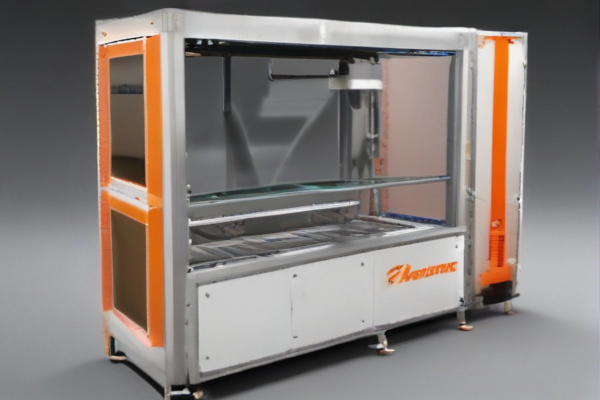

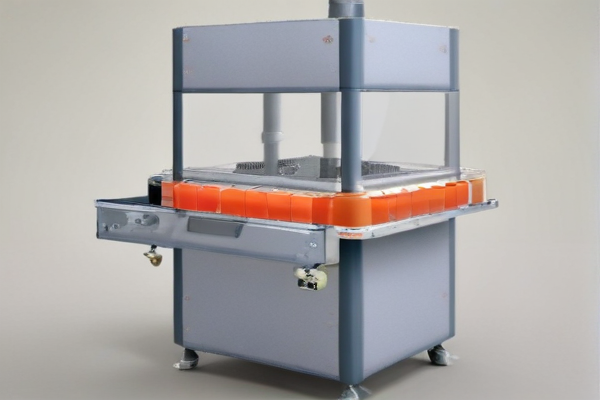

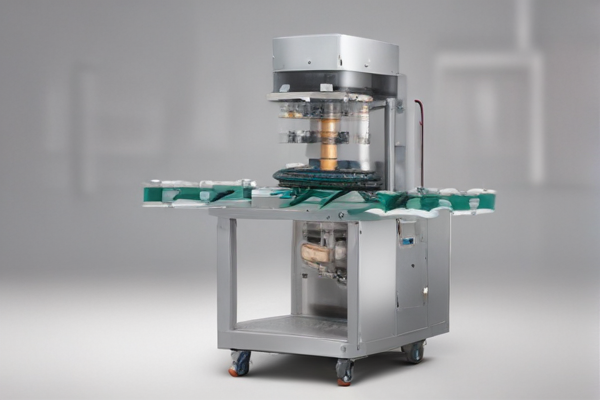

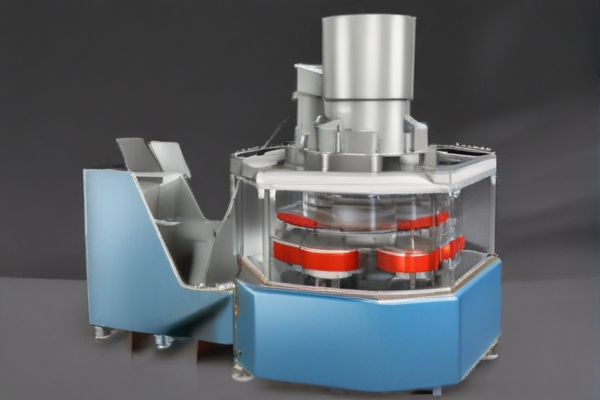

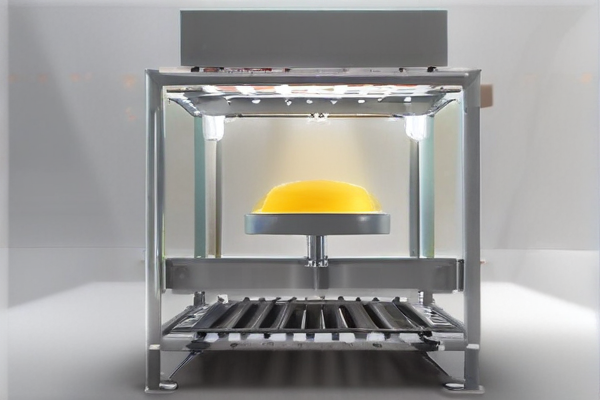

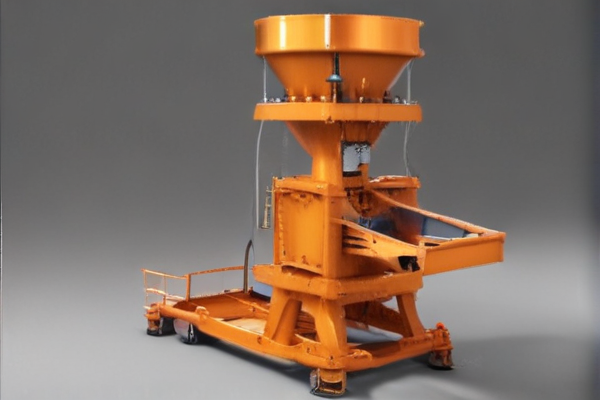

A cone packer machine streamlines the process of filling pre-rolled cones with herbal substances, ensuring consistency and efficiency. Ideal for both small-scale and large-scale production, this technology offers numerous advantages.

– High Efficiency: Increases production rate, saving time and labor costs.

– Consistency: Delivers uniformly packed cones, enhancing product quality.

– Scalability: Suitable for small businesses and large enterprises.

– Accuracy: Reduces wastage by precisely measuring and filling content.

– Hygiene: Automated process minimizes human contact, maintaining cleanliness.

– User-Friendly: Easy to operate with minimal training.

– Versatility: Compatible with various cone sizes and types.

– Durability: Built with robust materials for long-term use.

– Portability: Some models are compact and easy to move.

– Customization: Adjustable settings to meet specific requirements.

– Safety Features: Includes safeguards to prevent accidents.

– Cost-Effective: Reduces manual labor, lowering operational costs.

– Speed: Quickly fills multiple cones simultaneously.

– Quality Control: Maintains high standards throughout the production process.

– Reduces Product Loss: Effectively manages resources to minimize spillage.

– Enhances Branding: Consistent quality helps build brand reputation.

– Maintenance: Easy to clean and requires minimal upkeep.

– Operational Efficiency: Integrates seamlessly into existing workflows.

– Environmental Impact: Efficient design minimizes waste.

– Innovation: Incorporates advanced technology for optimal performance.

– Reliability: Provides dependable and continuous operation.

– Adaptability: Easily adjustable to cater to changing demands.

– Compliance: Meets industry standards and regulations.

– Customer Satisfaction: Consistently high-quality products delight consumers.

– Investment: Proves cost-effective over time with improved productivity.

– Enhanced Workflow: Streamlines production processes, improving overall efficiency.

– Market Growth: Facilitates business expansion into new markets.

– Precision: Ensures exact measurements for each cone.

– Ergonomic Design: Easy to handle and operate.

– After-Sales Support: Manufacturers often provide excellent customer service and support.