FAQ for Confectionery Packaging Machine Quality Work from SourcifyChina Factory

1. What types of confectionery packaging machines does SourcifyChina provide?

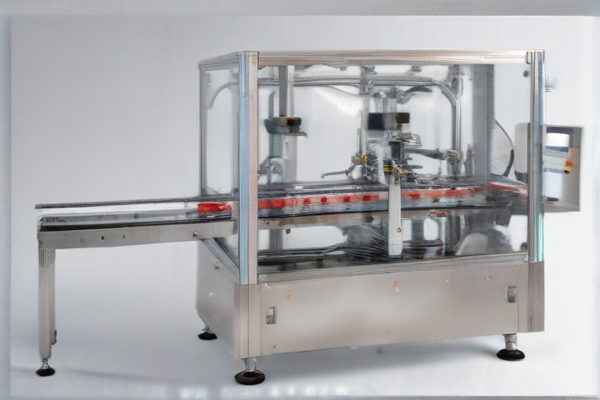

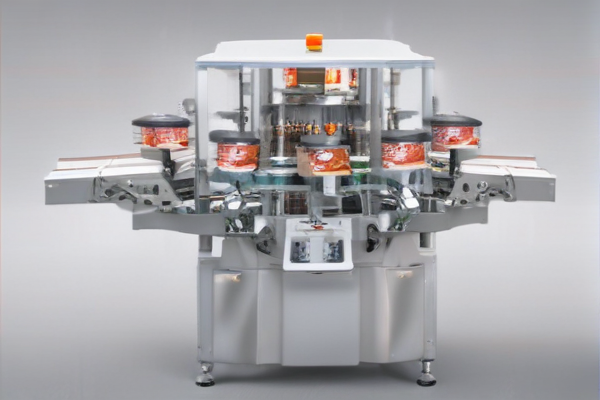

SourcifyChina manufactures a variety of packaging machines including flow wrappers, vertical form-fill-seal machines, blister packing machines, and cartoners suited for different confectionery products like chocolates, candies, and gummies.

2. How does SourcifyChina ensure the quality of their packaging machines?

SourcifyChina implements rigorous quality control measures including strict material selection, precision engineering, and multiple stages of testing to ensure each machine meets international standards and client specifications.

3. Are SourcifyChina’s machines customizable?

Yes, we offer customization options to meet specific client requirements such as machine size, speed, packaging styles, and additional features like automated feeding systems.

4. What is the average lead time for manufacturing and delivery?

The standard lead time ranges from 30 to 60 days, depending on the complexity and customization needed for the machine. SourcifyChina works closely with clients to meet their project timelines.

5. Do these machines support different types of materials?

Yes, SourcifyChina’s machines are designed to work with various packaging materials including plastic, aluminum foil, and paper-based laminates.

6. Is after-sales support available?

Absolutely, SourcifyChina offers comprehensive after-sales support including installation guidance, training, maintenance services, and spare parts supply to ensure smooth operation of the packaging machines.

7. What quality certifications do SourcifyChina’s machines have?

Our machines are certified under ISO 9001:2015, CE, and other relevant international quality standards, ensuring reliable and safe operation.

8. How can I get a quotation or more information?

For a quotation or more detailed information, you can contact us directly through our website or email at [email address]. Our sales team will get back to you promptly.

9. Are there any financing options available?

SourcifyChina offers various financing options depending on the client’s needs and project scale. Please discuss with our sales team to explore the available opportunities.

10. Can I visit the SourcifyChina factory?

Yes, we welcome clients to visit our manufacturing facility to see the production process and quality checks first-hand. Please schedule an appointment in advance.