Sure, here is a list of frequently asked questions (FAQ) with answers regarding manufacturing a conveyor system with quality work from SourcifyChina factory.

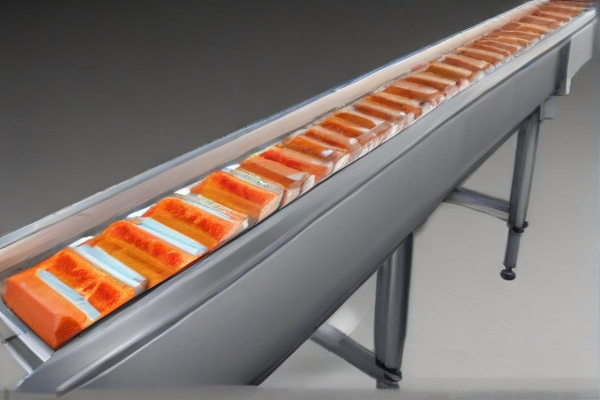

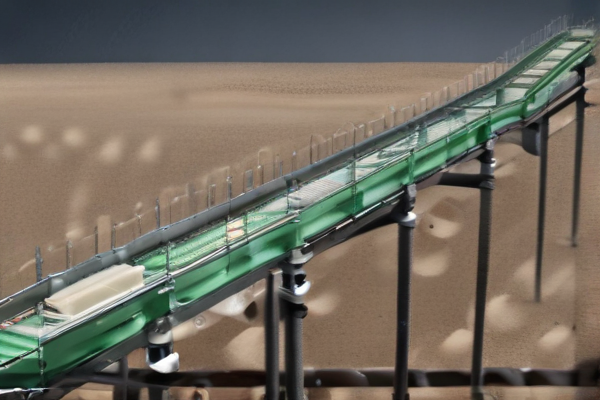

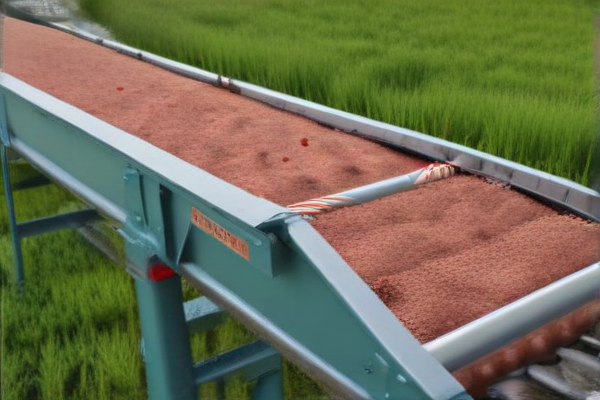

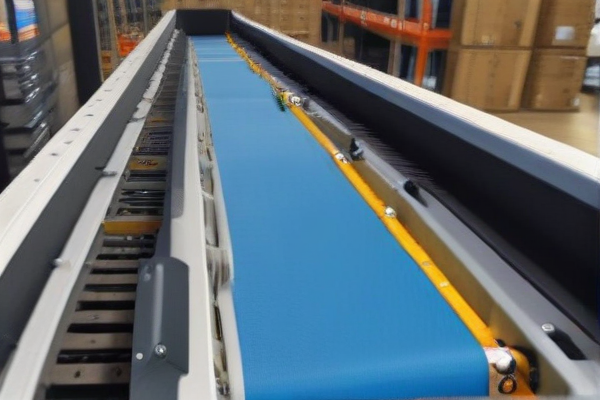

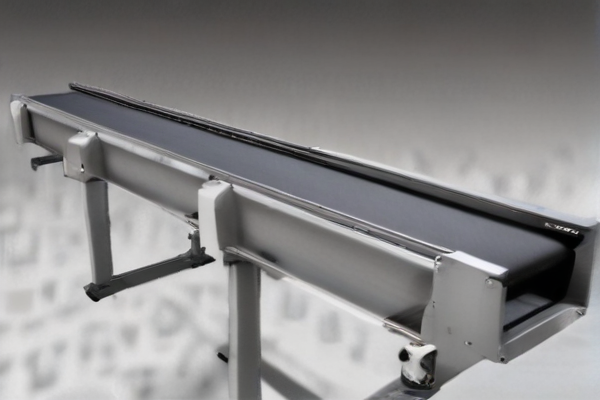

Q1: What types of conveyor systems can SourcifyChina manufacture?

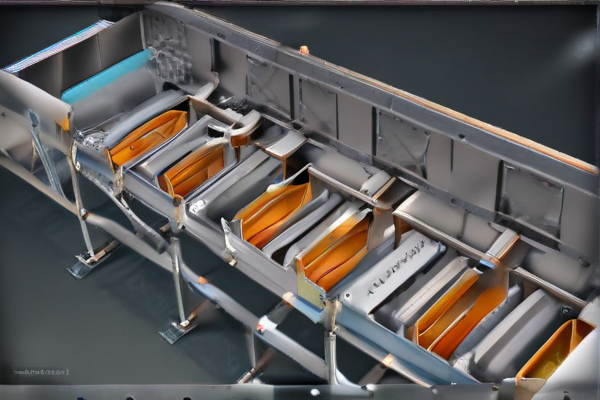

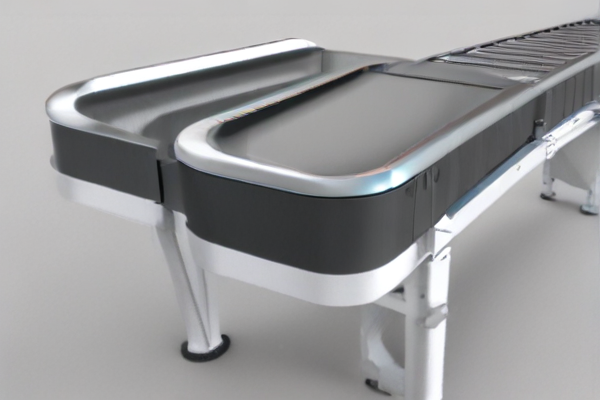

A1: SourcifyChina can manufacture various types of conveyor systems, including belt conveyors, roller conveyors, chain conveyors, screw conveyors, and more. Each type can be customized to meet specific operational needs.

Q2: What materials are used in the construction of these conveyor systems?

A2: Materials used can range from stainless steel and aluminum to plastic and rubber, depending on the application and industry requirements. High-quality, durable materials are chosen to ensure long-lasting performance and compliance with international standards.

Q3: How does SourcifyChina ensure the quality of its conveyor systems?

A3: SourcifyChina follows strict quality control measures including rigorous inspections, testing processes, and compliance with ISO standards to ensure each conveyor system meets high-quality benchmarks and customer specifications.

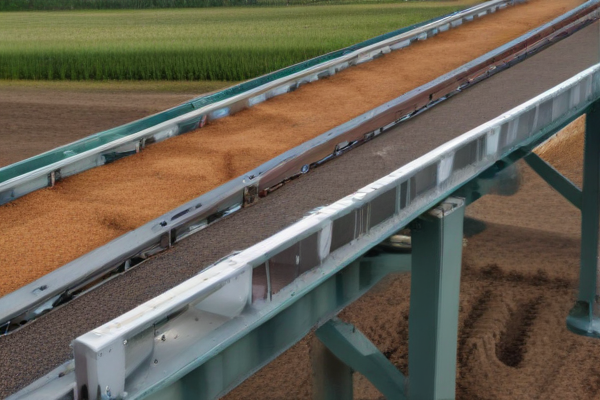

Q4: What industries does SourcifyChina serve?

A4: SourcifyChina serves a wide range of industries, such as food and beverage, pharmaceuticals, automotive, electronics, packaging, and many others. They tailor each conveyor system to the specific needs of the industry.

Q5: Can I customize the design of my conveyor system?

A5: Yes, SourcifyChina offers customization options to meet your precise requirements. You can specify dimensions, materials, load capacities, and other features to ensure the system fits your operational needs exactly.

Q6: What is the typical lead time for manufacturing a conveyor system at SourcifyChina?

A6: Lead times vary depending on the complexity and customization of the conveyor system. On average, it ranges from 4 to 12 weeks, including design, manufacturing, and quality assurance processes.

Q7: Does SourcifyChina provide after-sales support?

A7: Yes, SourcifyChina offers comprehensive after-sales support, including installation assistance, maintenance services, and technical support to ensure the smooth operation of your conveyor system.

Q8: How can I get a quote for a conveyor system from SourcifyChina?

A8: You can get a quote by contacting SourcifyChina directly via their website, email, or phone. Providing detailed specifications and requirements will help them give you an accurate and prompt quote.

Q9: Are there any minimum order requirements?