Sure! Below is a list of Frequently Asked Questions (FAQ) along with their answers about sourcing cosmetic packaging machines from SourcifyChina factory:

1. What types of cosmetic packaging machines does SourcifyChina factory offer?

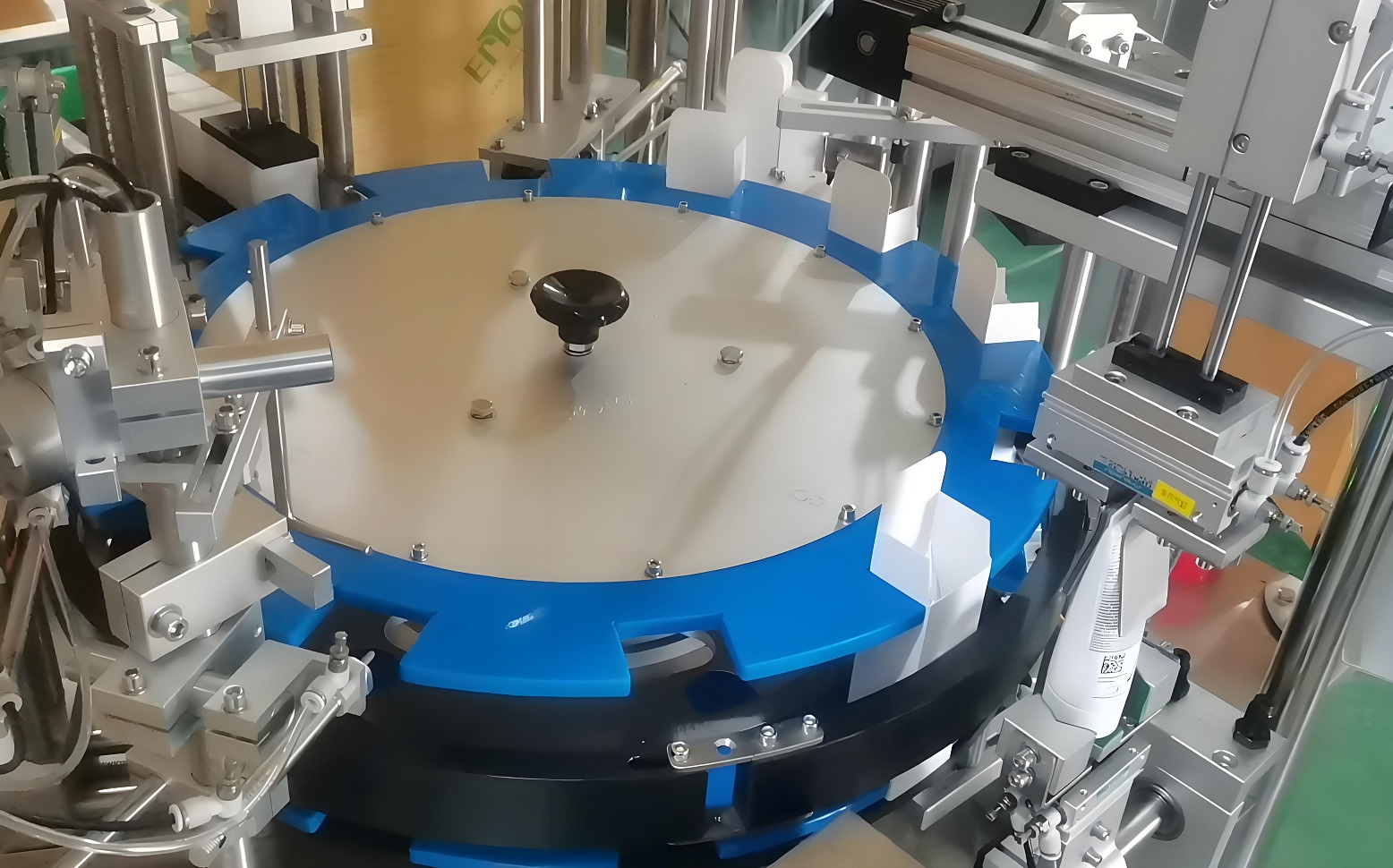

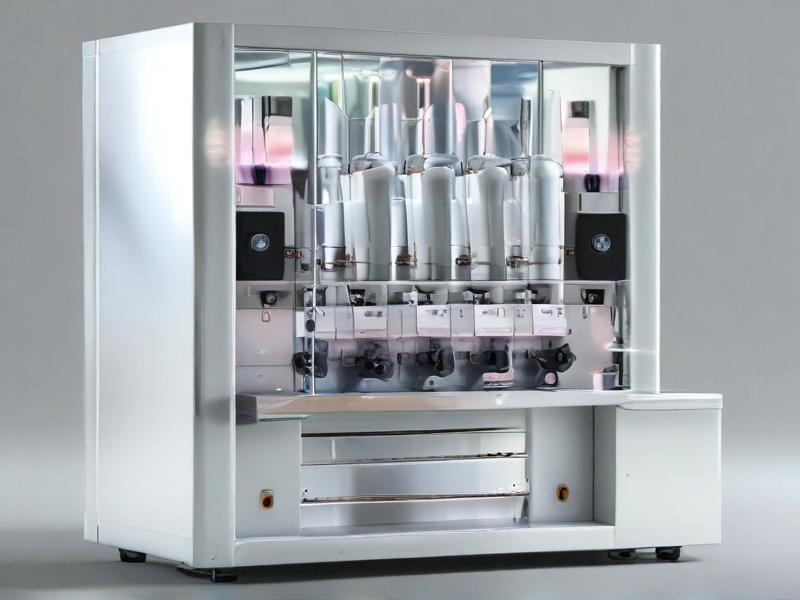

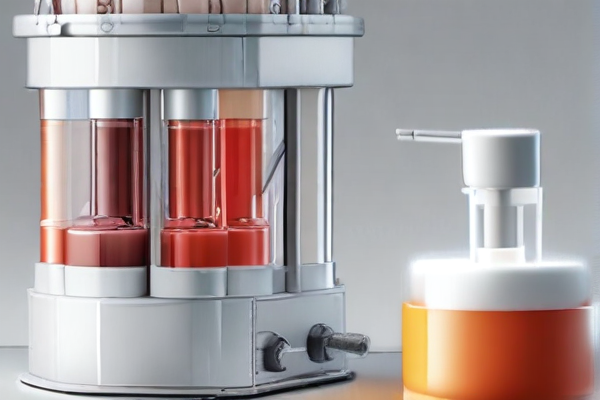

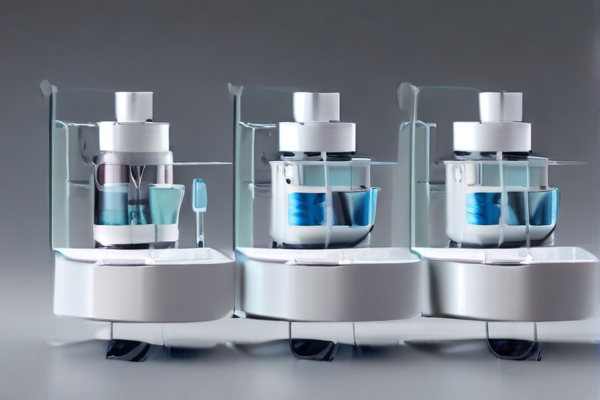

SourcifyChina factory offers a wide range of cosmetic packaging machines, including filling machines, capping machines, labeling machines, and complete packaging lines tailored to cosmetic products.

2. How can I request a quote for a cosmetic packaging machine?

You can request a quote by visiting SourcifyChina’s official website and filling out the inquiry form with your specific requirements or by contacting their sales team directly via email or phone.

3. What information is needed to get an accurate quote?

To get an accurate quote, provide details such as the type of cosmetic product, packaging type, production capacity, specific technical requirements, and any customization needs.

4. Are there any minimum order requirements?

Minimum order requirements vary based on the specific machine and customization level. It’s best to check with SourcifyChina’s sales team for precise details on your specific order.

5. What is the lead time for manufacturing and delivery?

Lead times can vary depending on the complexity of the machine and order volume. Typically, it ranges from 4-10 weeks. For exact timelines, consult the factory’s sales team.

6. Is it possible to customize the machines according to my specifications?

Yes, SourcifyChina factory offers customization options to meet specific needs, ensuring the equipment aligns perfectly with your production requirements.

7. What kind of support and after-sales services does SourcifyChina offer?

They provide comprehensive support including installation, training, maintenance, and technical support to ensure optimal performance of the machines.

8. How can I be assured of the quality of the machines?

SourcifyChina adheres to strict quality control processes and international standards. You can also request for samples, certifications, and even visit the factory for quality assurance.

9. Do they offer global shipping?

Yes, SourcifyChina offers global shipping services. They handle logistics to ensure your equipment is delivered safely and efficiently regardless of your location.

10. What payment methods are accepted?

SourcifyChina supports various payment methods including wire transfer (T/T), L/C at sight, and other mutually agreed payment terms.