Cosmetics filling machines are essential for accurately dispensing products into containers. They vary by function and type, including manual, semi-automatic, and fully-automatic machines, each offering different capabilities for product consistency and efficiency.

– Manual Filling Machines:

– Operator-controlled

– Ideal for small-scale production

– Cost-effective

– Semi-Automatic Filling Machines:

– Operator initiates filling cycle

– Increased throughput compared to manual

– Suitable for mid-sized businesses

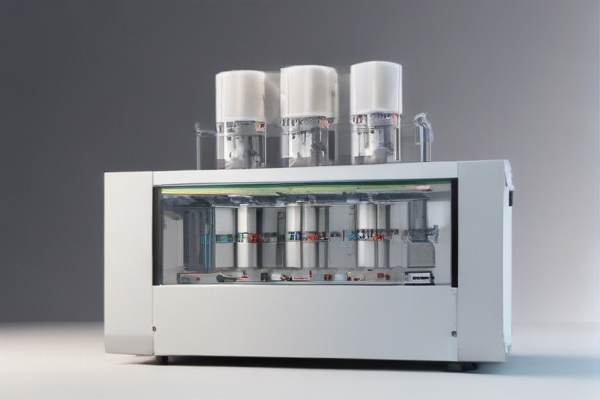

– Fully-Automatic Filling Machines:

– Automated filling process

– High-speed, large-scale production

– Consistent fill volumes, minimizing waste

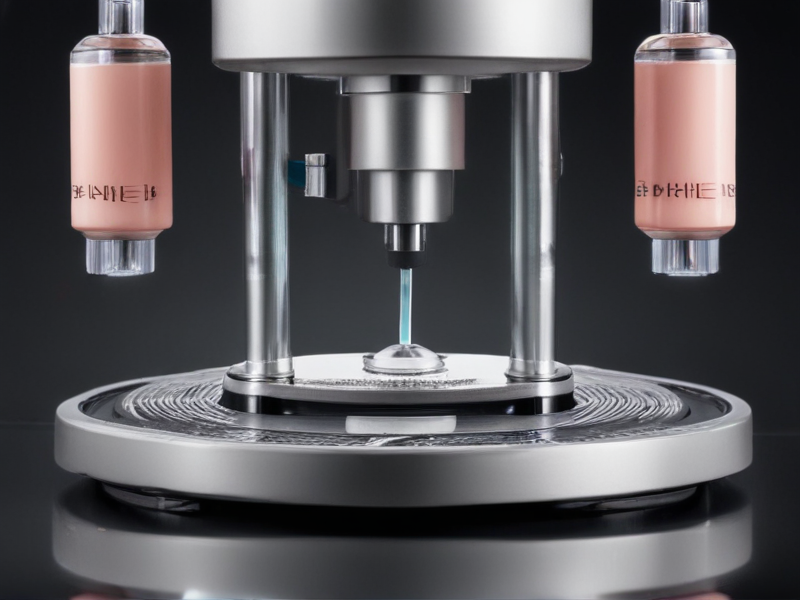

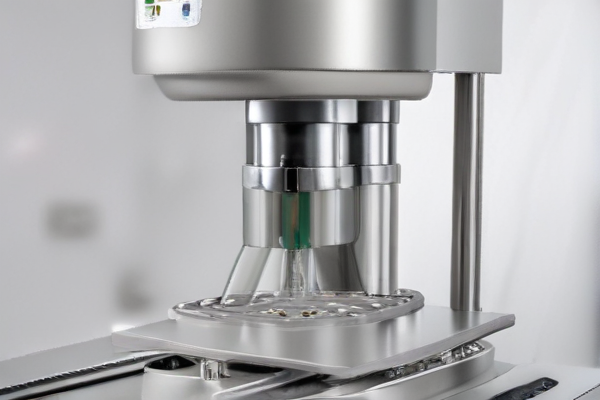

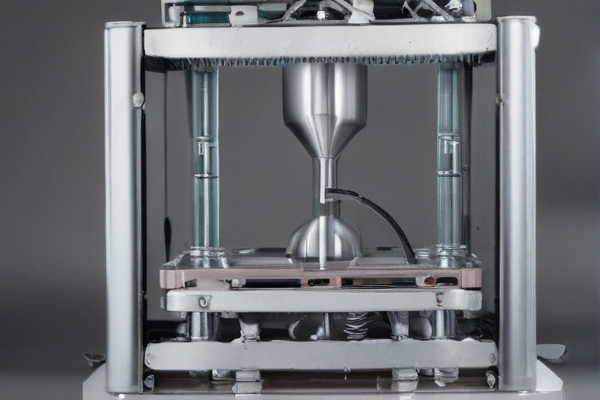

– Piston Fillers:

– Uses a piston to measure product volume

– Ideal for thick, viscous products

– Highly accurate

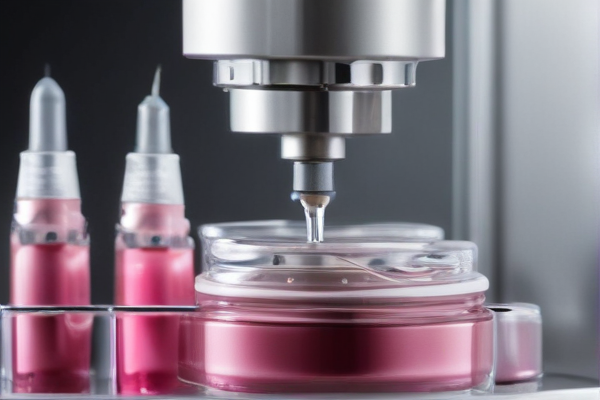

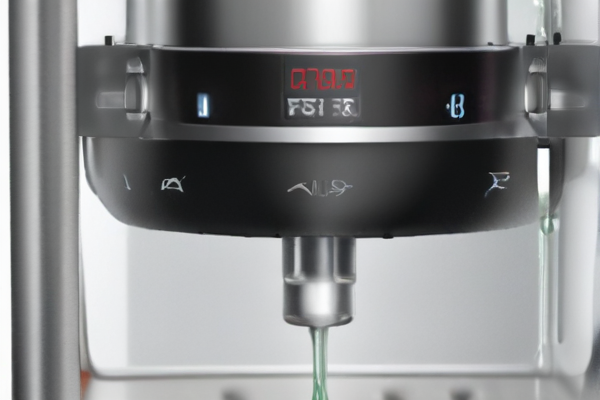

– Peristaltic Fillers:

– Uses a peristaltic pump to push product through tubing

– Suitable for sensitive or sterile products

– Easy to clean and sterile

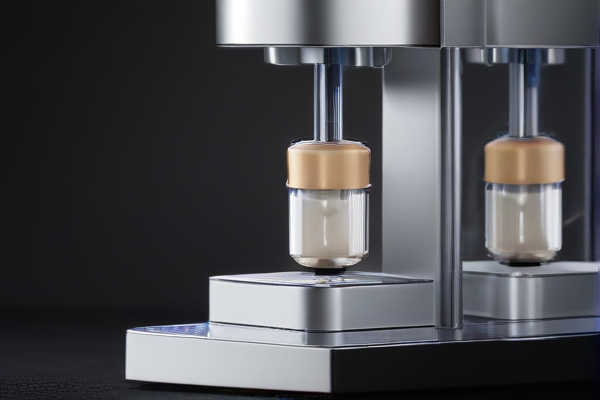

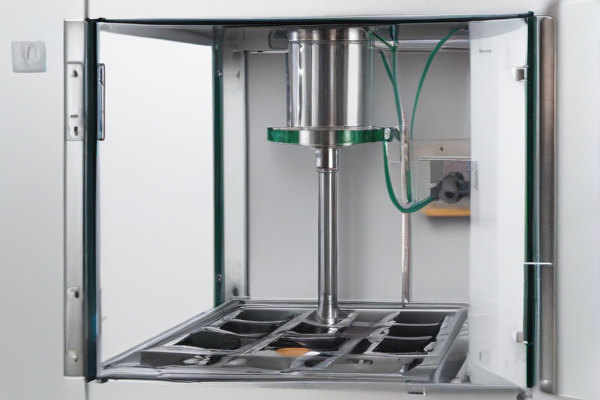

– Vacuum Fillers:

– Utilizes vacuum pressure for filling

– Suitable for filling glass bottles

– Ensures precise fill levels

– Overflow Fillers:

– Ensures consistent fill levels

– Ideal for transparent containers

– Good for free-flowing liquids

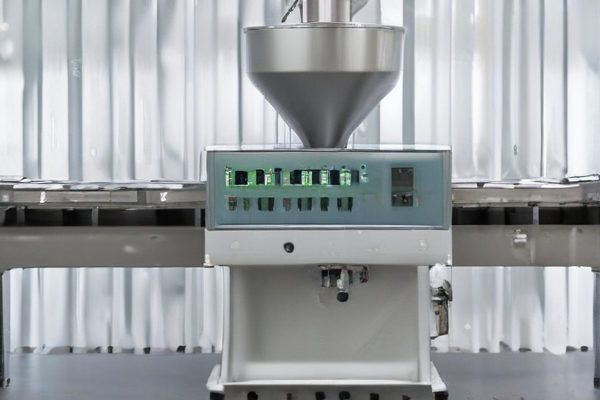

– Auger Fillers:

– Uses a rotating auger for filling

– Best for powders and granules

– Consistent and accurate filling

– Pump Fillers:

– Uses a pumping mechanism to transfer product

– Suitable for a wide range of viscosities

– Precise dosing for complex formulations

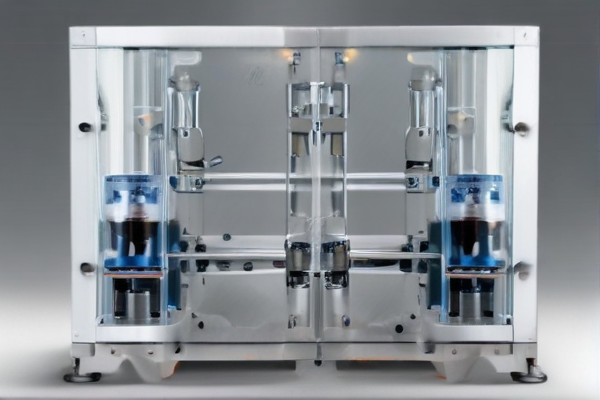

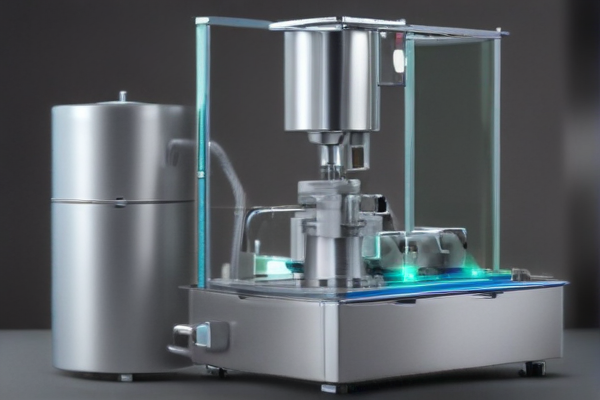

– Inline Filling Systems:

– Larger scale operations

– Multiple containers filled simultaneously

– High efficiency and speed

– Rotary Filling Systems:

– Containers filled in a rotating sequence

– Continuous operation