Sure, here’s a list of frequently asked questions (FAQs) with answers for the manufacturing quality of a cream bottle filling machine from SourcifyChina factory:

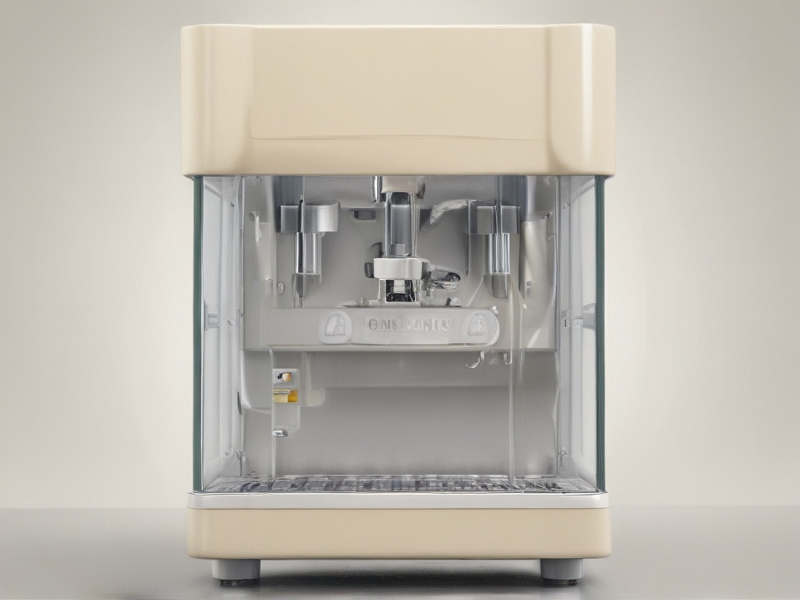

Q1: What materials are used in the manufacturing of the cream bottle filling machine?

A1: SourcifyChina uses high-quality stainless steel, specifically SS304 and SS316, to ensure durability, corrosion resistance, and compliance with hygiene standards required in the cosmetics production industry.

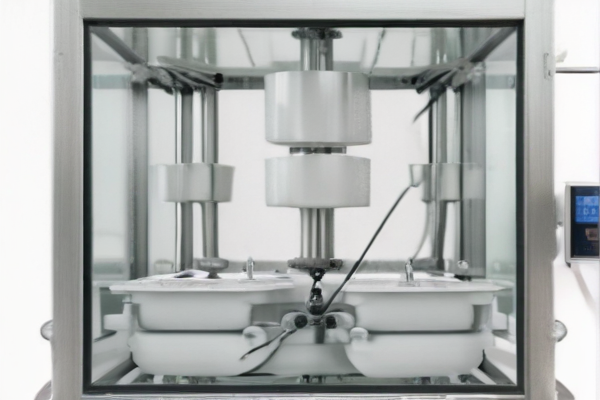

Q2: How do you ensure the accuracy and consistency of the filling process?

A2: Our machines are equipped with advanced filling technology, such as servo-controlled auger filling mechanisms and high-precision sensors, to maintain consistent volume accuracy within ±1% tolerance.

Q3: What quality control measures are in place during manufacturing?

A3: SourcifyChina adheres to strict quality control protocols, including raw material inspection, in-process quality checks, and comprehensive final testing to ensure each machine meets international standards like ISO 9001 and CE certification.

Q4: Are your machines compatible with different bottle sizes and types?

A4: Yes, our cream bottle filling machines are versatile and can be customized with adjustable settings or interchangeable parts to handle various bottle shapes, sizes, and materials.

Q5: How is the machine’s operational efficiency and downtime minimized?

A5: We incorporate user-friendly interfaces, automated cleaning systems, and easy-to-maintain components to ensure high operational efficiency and minimal downtime.

Q6: What kind of after-sales support and warranty do you provide?

A6: SourcifyChina provides a 1-year warranty on all machines along with lifetime technical support. Our dedicated service team is available for remote assistance and on-site service if needed.

Q7: How long does it take to manufacture and deliver a cream bottle filling machine?

A7: The standard lead time for manufacturing is around 4-6 weeks, depending on customization requirements. Shipping times vary based on destination but typically range from 1-3 weeks.

Q8: Can you provide training and installation services?

A8: Yes, we offer comprehensive training sessions and installation services to ensure your staff can operate the machine efficiently and safely.

Q9: Are your machines energy-efficient?

A9: Yes, our machines are designed with energy-efficient motors and integrated controls to reduce power consumption and operational costs.

Q10: Do you offer customization options for specific production needs?