Cup filling machines are essential for efficiently dispensing liquids, semi-solids, or powders into cups. They come in various types, including manual, semi-automatic, and fully automatic systems, tailored to different production scales and requirements.

– Manual Cup Filling Machines

– Ideal for small-scale operations.

– Require human intervention.

– Cost-effective.

– Suitable for startups and low-volume production.

– Semi-Automatic Cup Filling Machines

– Combination of manual and automatic functions.

– Improved speed and precision compared to manual machines.

– Moderate cost.

– Versatile for various cup sizes and products.

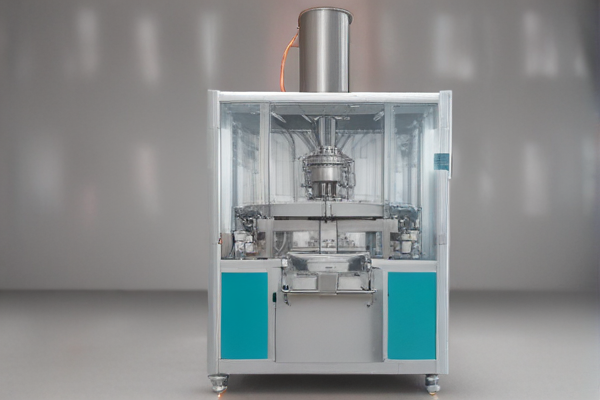

– Fully Automatic Cup Filling Machines

– High-speed, high-precision operations.

– Minimal human intervention required.

– Integrated with additional features like sealing, labeling, and capping.

– Suitable for large-scale production lines.

– Rotary Cup Filling Machines

– Efficient for high-output production.

– Continuous rotary motion for filling.

– Occupy less space, making them suitable for compact production areas.

– Linear Cup Filling Machines

– Cups move in a linear path.

– Flexibility in production processes.

– Easy integration with other machinery for complex production lines.

– Multi-Head Cup Filling Machines

– Multiple filling heads increase productivity.

– Ideal for high-volume production.

– Available in both rotary and linear models.

– Features to Consider

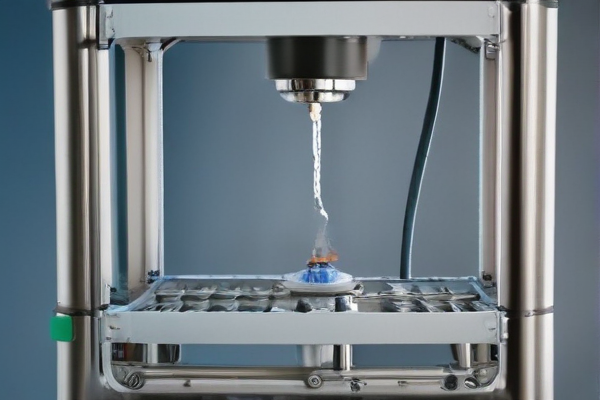

– Material Compatibility: Ensure the machine can handle the specific consistency and chemical properties of your product.

– Speed and Efficiency: Match the machine’s output capabilities with your production needs.

– Precision and Accuracy: Critical for maintaining product consistency and minimizing waste.

– Ease of Cleaning and Maintenance: Important for hygiene and machine longevity.

– Customization Options

– Tailored to specific product types (e.g., dairy, beverages, sauces).

– Adjustable settings for different cup sizes and fill levels.

– Optional integration with sterilization and packaging systems.

Each type of cup filling machine offers various advantages depending on your production needs, making it essential to choose the right one for optimal efficiency and product quality.