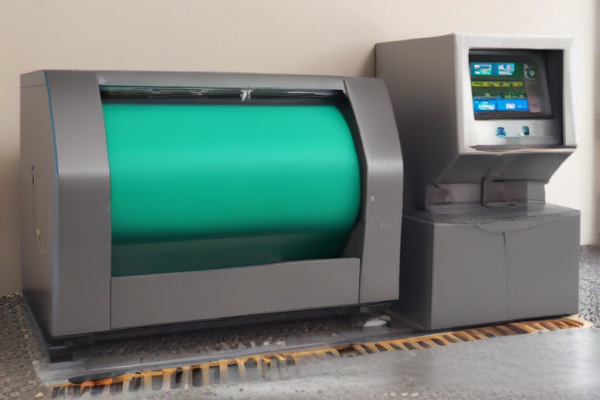

Q1: What is a depositing machine?

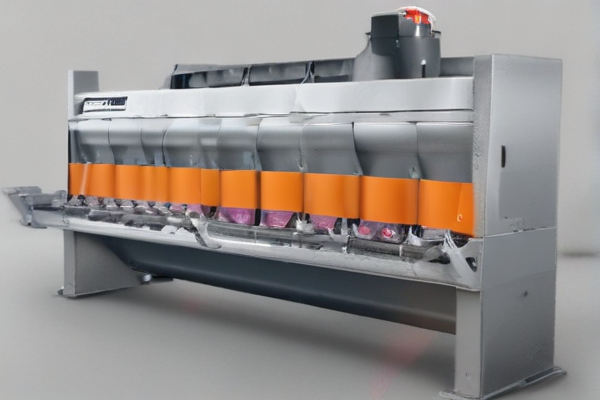

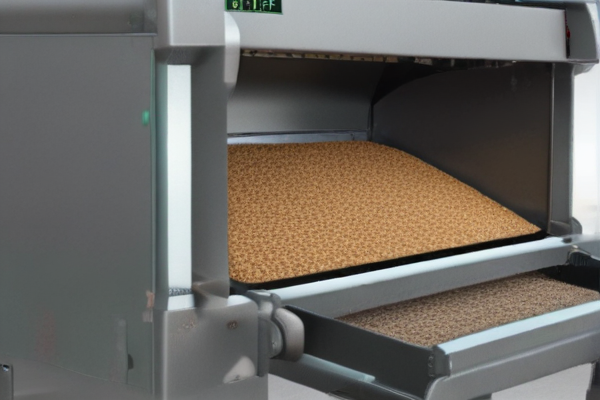

A1: A depositing machine is used in manufacturing to deposit specific amounts of materials, like chocolate, jelly, or other substances, into molds or onto surfaces with high precision and consistency.

Q2: What types of depositing machines does SourcifyChina factory offer?

A2: SourcifyChina factory offers various types of depositing machines, including chocolate depositors, jelly depositors, and batter depositors, designed to meet different manufacturing needs.

Q3: How does SourcifyChina maintain the quality of their depositing machines?

A3: SourcifyChina maintains quality by adhering to strict manufacturing standards, using high-grade materials, employing skilled technicians, and conducting comprehensive testing on each machine before delivery.

Q4: What materials are used in SourcifyChina’s depositing machines?

A4: SourcifyChina uses durable and food-grade materials such as stainless steel and high-quality alloys to ensure the machines are safe, reliable, and long-lasting.

Q5: Can SourcifyChina customize depositing machines according to specific requirements?

A5: Yes, SourcifyChina offers customization options based on unique manufacturing needs, including size, capacity, and specific design requirements.

Q6: What is the delivery time for a depositing machine from SourcifyChina?

A6: Delivery times vary based on customization and order size but typically range from 4 to 8 weeks.

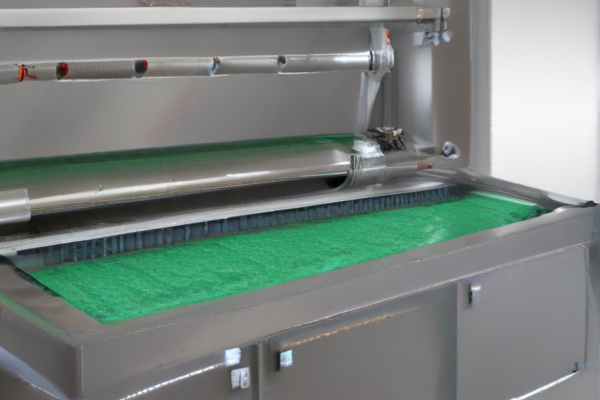

Q7: What maintenance is required for the depositing machines?

A7: Regular maintenance includes cleaning, inspection of moving parts, lubrication, and periodic professional servicing to ensure optimal performance and longevity.

Q8: Does SourcifyChina provide technical support and training for operating their machines?

A8: Yes, SourcifyChina offers comprehensive technical support, including training for machine operation, troubleshooting, and maintenance.

Q9: Are spare parts available for depositing machines from SourcifyChina?

A9: Yes, SourcifyChina provides a full range of spare parts and ensures availability to support ongoing maintenance and repair.

Q10: How can I place an order with SourcifyChina factory for a depositing machine?

A10: Orders can be placed through their official website, contacting their sales team directly, or via authorized distributors. Details and guidance are available on their website.