Here is a list of frequently asked questions (FAQ) regarding the quality of detergent powder packing machines manufactured by SourcifyChina factory:

1. What type of materials are used in the construction of the packing machines?

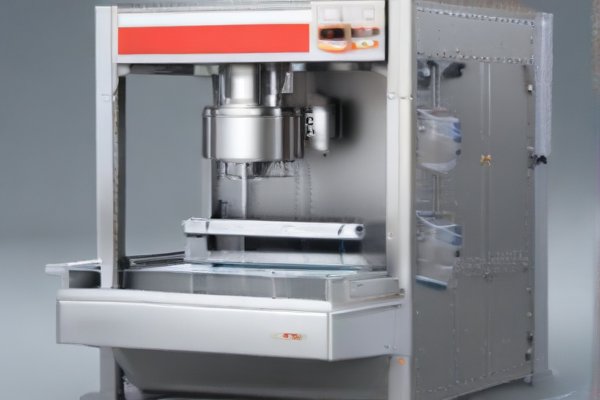

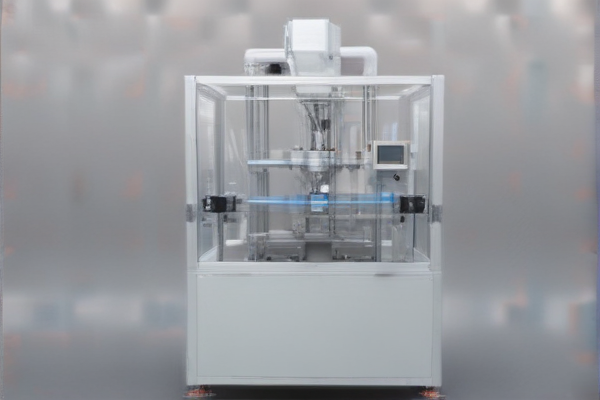

Our detergent powder packing machines are made from high-quality, industrial-grade stainless steel to ensure durability, corrosion resistance, and long-lasting performance.

2. Are the machines compatible with different types of detergent powders?

Yes, our machines are designed to handle a variety of detergent powders, including fine, coarse, and moisture-sensitive formulations. Customization options are available for specific requirements.

3. How is the quality of the machines ensured?

All machines undergo rigorous quality control checks at various stages of production. We adhere to international manufacturing standards and use advanced testing methods to ensure top-notch quality.

4. Can the machines be customized to meet specific packaging needs?

Absolutely. We offer customizable options in terms of machine size, packaging capacity, speed, and additional features to meet your specific requirements.

5. What is the packaging speed of these machines?

The packaging speed varies depending on the model. On average, our machines can pack between 30 to 120 bags per minute, depending on the complexity and size of the package.

6. Do you offer training and support for machine operation?

Yes, we provide comprehensive training and support for the installation, operation, and maintenance of our machines. Our technical support team is available 24/7 to assist you.

7. What is the warranty period for your packing machines?

We offer a one-year warranty on all our detergent powder packing machines, covering any manufacturing defects and ensuring free repairs or replacements within this period.

8. How energy-efficient are your packing machines?

Our machines are designed with energy efficiency in mind. They use advanced technology to minimize power consumption while maximizing operational efficiency.

9. Are spare parts readily available?

Yes, we maintain a stock of essential spare parts to ensure quick replacements and minimal downtime. Spare parts can be shipped globally as needed.

10. How can I place an order or request a quote?

You can contact our sales team via email or our official website. Provide your requirements, and we will respond promptly with a detailed quote and further purchasing instructions.