Sure! Here is a concise FAQ list regarding the manufacturing of drug packaging machines by SourcifyChina factory:

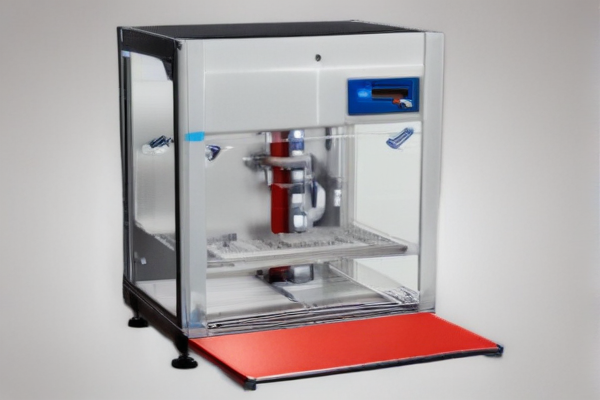

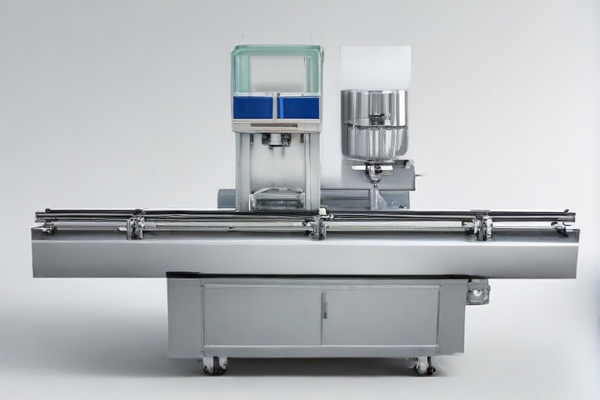

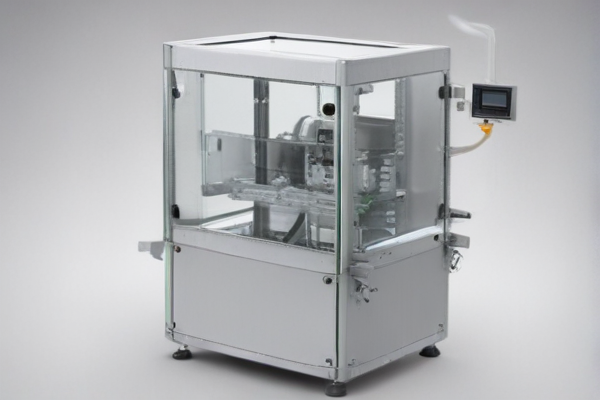

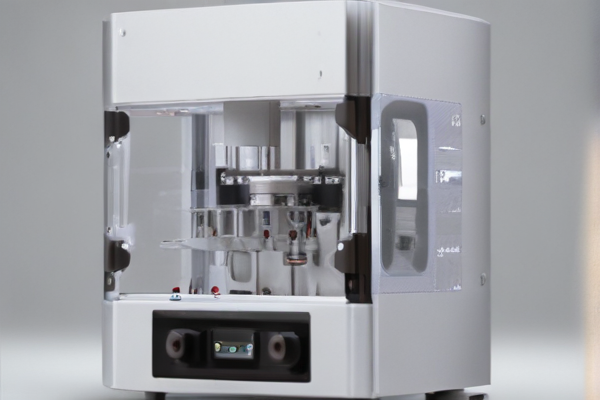

Q1: What types of drug packaging machines does SourcifyChina manufacture?

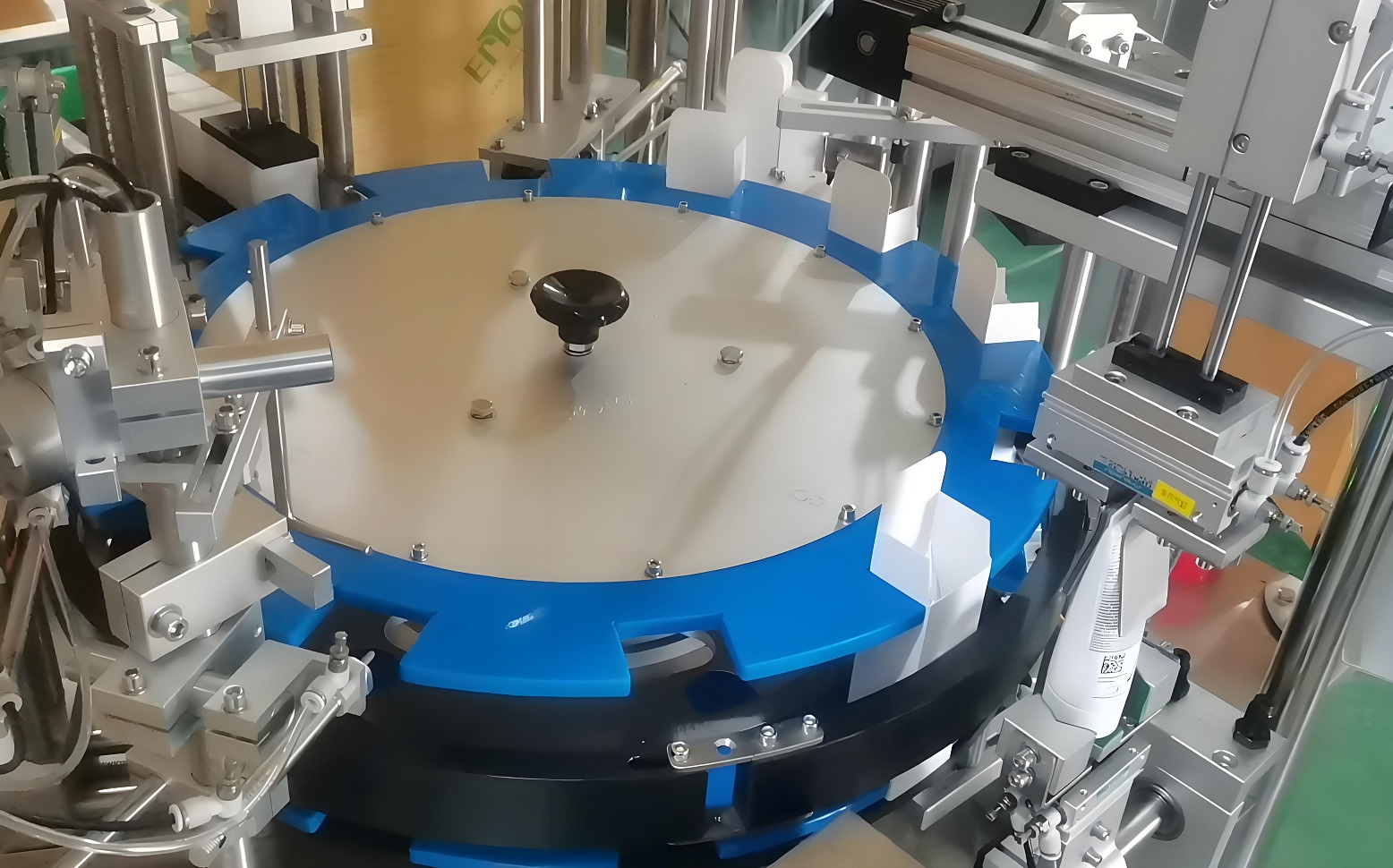

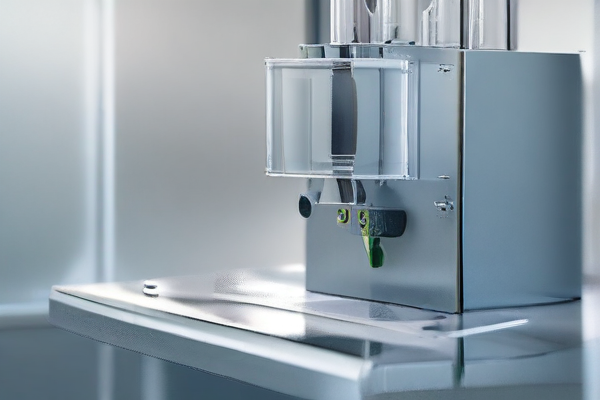

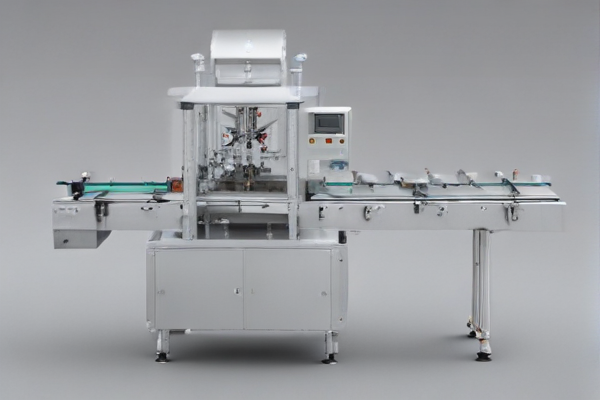

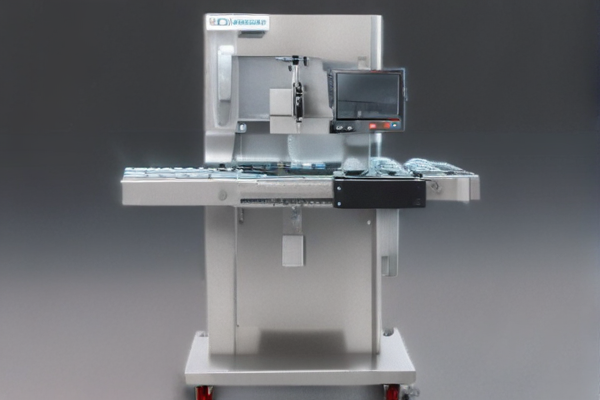

A1: SourcifyChina manufactures a wide range of drug packaging machines including blister packaging machines, strip packaging machines, bottle filling machines, cartoning machines, and sterilization equipment.

Q2: How does SourcifyChina ensure the quality of its drug packaging machines?

A2: SourcifyChina guarantees quality through stringent quality control measures, ISO certifications, regular audits, testing of machines during and post-production, and using high-grade materials for manufacturing.

Q3: Can the machines be customized according to specific requirements?

A3: Yes, SourcifyChina offers customization options to meet specific needs, including machine size, speed, configurations, and special features required by clients.

Q4: What is the lead time for manufacturing and delivery?

A4: The lead time varies based on machine complexity and customization. Generally, standard machines have a lead time of 4-8 weeks, while customized solutions may take longer. Accurate delivery timelines are provided upon order confirmation.

Q5: What support does SourcifyChina offer post-purchase?

A5: SourcifyChina provides comprehensive after-sales support, including installation assistance, training for operating staff, maintenance services, and a warranty period during which faulty parts are replaced or repaired.

Q6: Are the drug packaging machines from SourcifyChina compliant with international standards?

A6: Yes, SourcifyChina ensures that all drug packaging machines comply with international standards, including GMP, FDA, CE, and other relevant pharmaceutical equipment regulations.

Q7: How does SourcifyChina handle spare parts and maintenance?

A7: SourcifyChina maintains an inventory of spare parts and provides prompt delivery to minimize downtime. They also offer maintenance contracts and technical support to keep the machines in optimum working condition.

Q8: What are the payment terms for purchasing from SourcifyChina?

A8: Payment terms vary, but typically include an initial deposit with the balance payable upon delivery or through a Letter of Credit (L/C). Details are discussed and agreed upon during the sales negotiation.

This FAQ seeks to address common inquiries succinctly within the 300-word limit. Should you have further questions, SourcifyChina’s customer service is available to assist.