Sure, here are some frequently asked questions (FAQ) with answers regarding sourcing an eye drop filling machine from SourcifyChina factory:

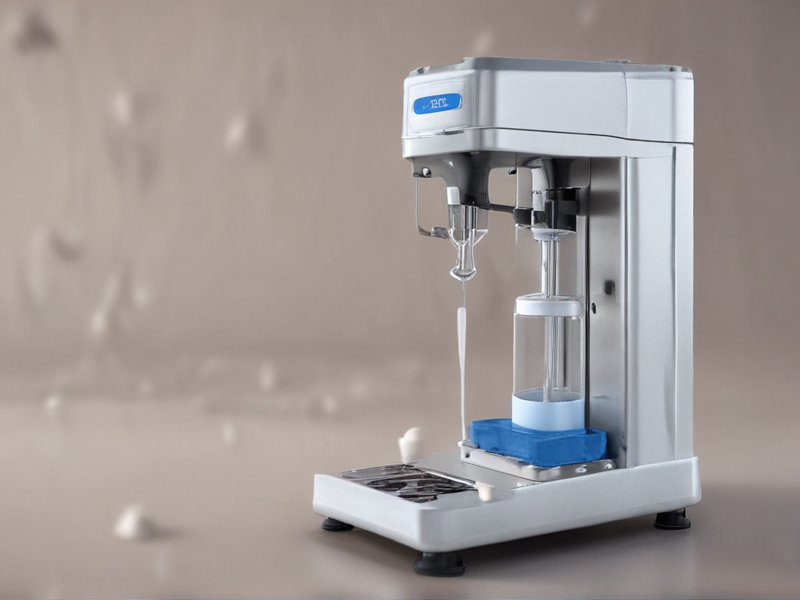

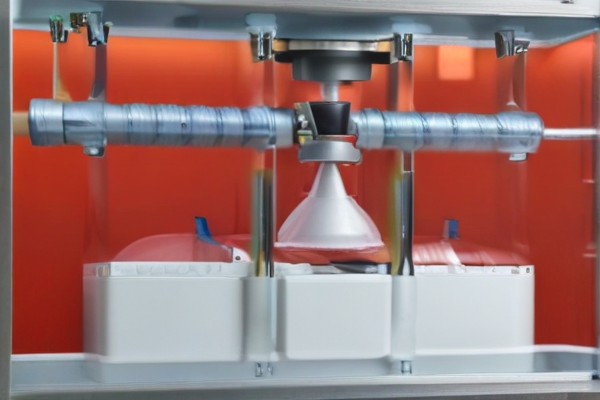

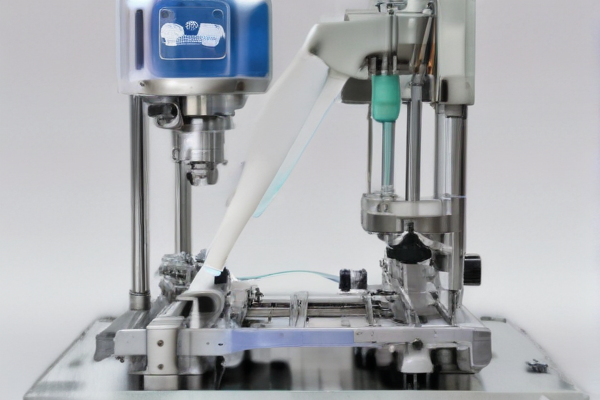

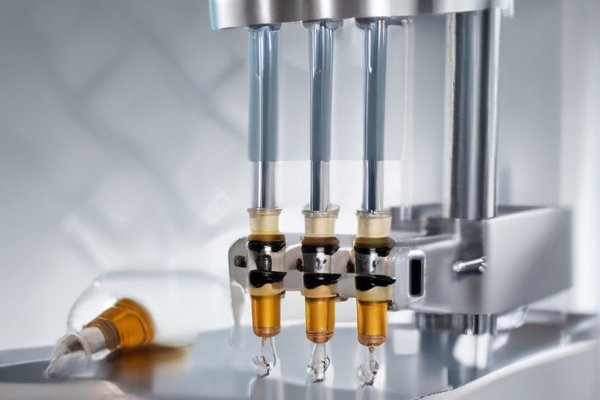

1. What types of eye drop filling machines does SourcifyChina offer?

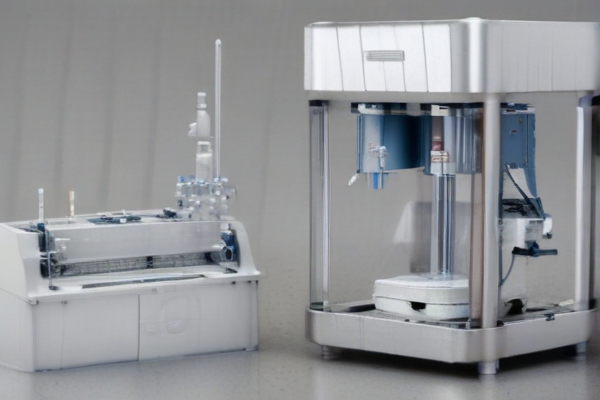

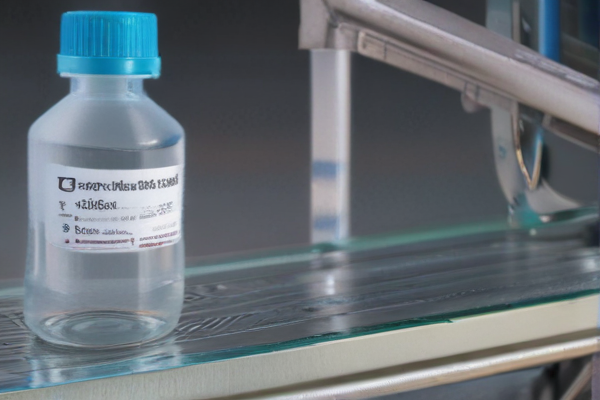

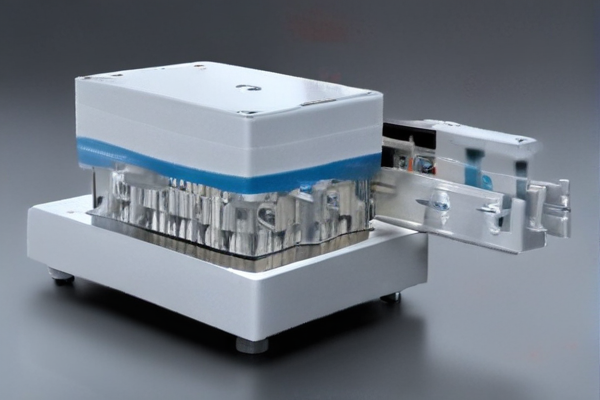

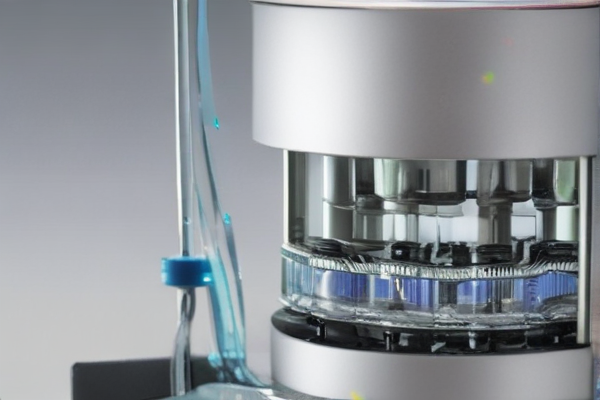

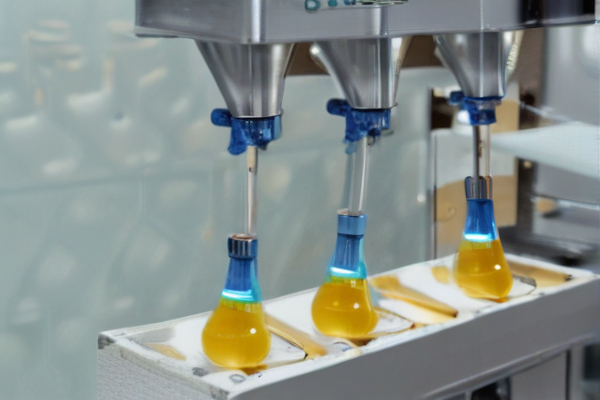

SourcifyChina offers a variety of eye drop filling machines including automatic, semi-automatic, and manual models. These machines can handle different volume capacities and production speeds to meet diverse production needs.

2. How can I request a quote for an eye drop filling machine?

To request a quote, visit the SourcifyChina website and fill out the inquiry form with your specific requirements. Alternatively, you can contact their sales team directly via email or phone.

3. What are the payment terms for purchasing an eye drop filling machine?

The payment terms typically include a deposit upon order confirmation and the remaining balance before shipment. Payment methods may include bank transfers (T/T), L/C, and others as agreed upon.

4. How long is the delivery time for an eye drop filling machine?

The delivery time varies depending on the specific machine model and any customization requirements. Generally, it ranges from 30 to 60 days after order confirmation and receipt of the deposit.

5. Does SourcifyChina provide installation and training services?

Yes, SourcifyChina offers installation and training services. Technicians can be sent to your facility to ensure proper installation and provide training to your operators.

6. What is the warranty period for the eye drop filling machines?

SourcifyChina typically provides a one-year warranty for their eye drop filling machines. The warranty covers manufacturing defects and provides spare parts and technical support.

7. Can the machines be customized to specific production needs?

Yes, SourcifyChina can customize machines according to specific production requirements, including modifications in design, capacity, and other technical specifications.

8. What kind of after-sales support does SourcifyChina offer?

SourcifyChina offers comprehensive after-sales support including technical assistance, spare parts supply, and maintenance services to ensure continuous and efficient operation of the machines.

9. Are there any certifications for the eye drop filling machines?

Yes, SourcifyChina’s eye drop filling machines adhere to international standards and come with necessary certifications such as CE, GMP, and ISO to ensure quality and compliance.