Sure, here are some FAQs and answers about the quality of eye drop filling machines from SourcifyChina factory:

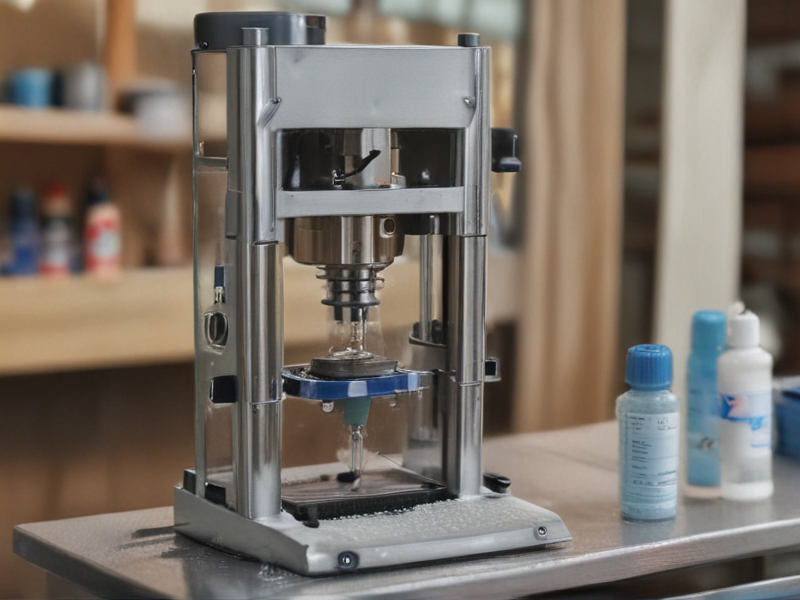

1. What materials are used in the construction of your eye drop filling machines?

Our eye drop filling machines are constructed using high-quality stainless steel and FDA-approved materials to ensure durability and safety for pharmaceutical applications.

2. How do you ensure the precision of the filling process?

We use advanced servo motor technology and high-precision dosing pumps to ensure the accuracy of the filling process, keeping variance within a minimal range.

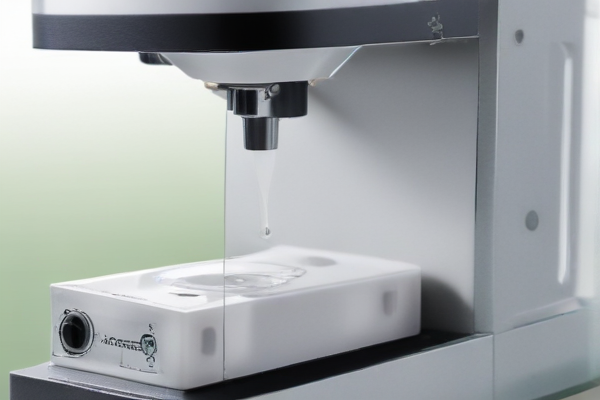

3. Are your machines compliant with international standards?

Yes, our machines meet international standards such as ISO, CE, and cGMP requirements, ensuring they are suitable for global markets and high-quality production demands.

4. What kind of maintenance do your machines require?

Our machines are designed for minimum maintenance, featuring easy disassembly and cleaning. We provide a detailed maintenance schedule and support services to help you maintain optimal machine performance.

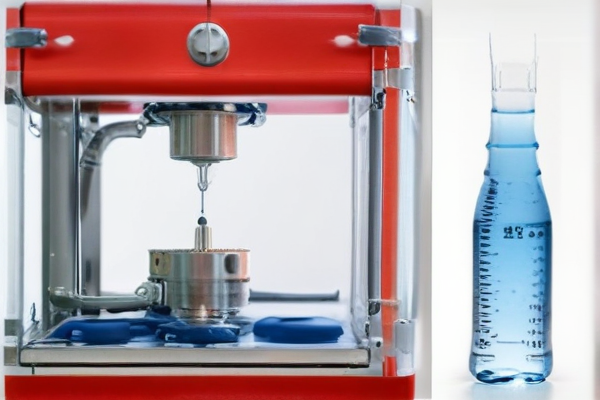

5. How does SourcifyChina ensure the quality of its machines before shipment?

We conduct rigorous quality control tests, including performance testing, safety checks, and material quality assessments. Each machine undergoes a factory acceptance test (FAT) before shipment to ensure it meets all specified standards.

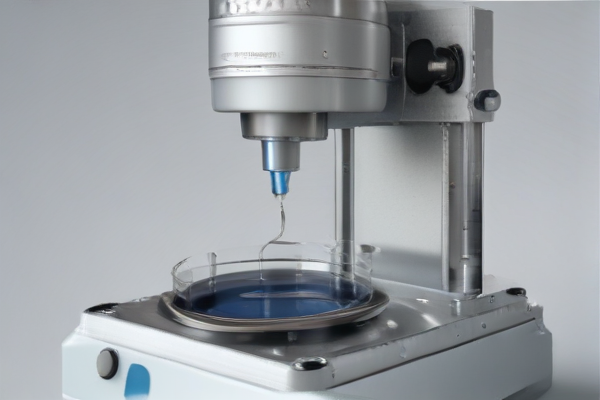

6. Can your machines be customized to meet specific requirements?

Yes, we offer customization options to meet specific production requirements, including varying bottle sizes, filling volumes, and production rates.

7. What kind of after-sales support do you provide?

We offer comprehensive after-sales support, including technical assistance, spare parts supply, and on-site training to help you get the most out of your investment.

8. How long is the warranty period for your machines?

Our machines come with a standard one-year warranty, during which we provide free repairs and parts replacement for any manufacturing defects. Extended warranty options are also available.

9. Do you provide installation and commissioning services?

Yes, we offer professional installation and commissioning services to ensure your machine is set up correctly and operates efficiently from day one.

10. Can you provide references or case studies from satisfied customers?

Absolutely, we can provide references and case studies upon request, showcasing the performance and reliability of our eye drop filling machines in different production environments.