Sure! Here’s a list of frequently asked questions (FAQ) with answers for sourcing a fastener packaging machine from SourcifyChina factory.

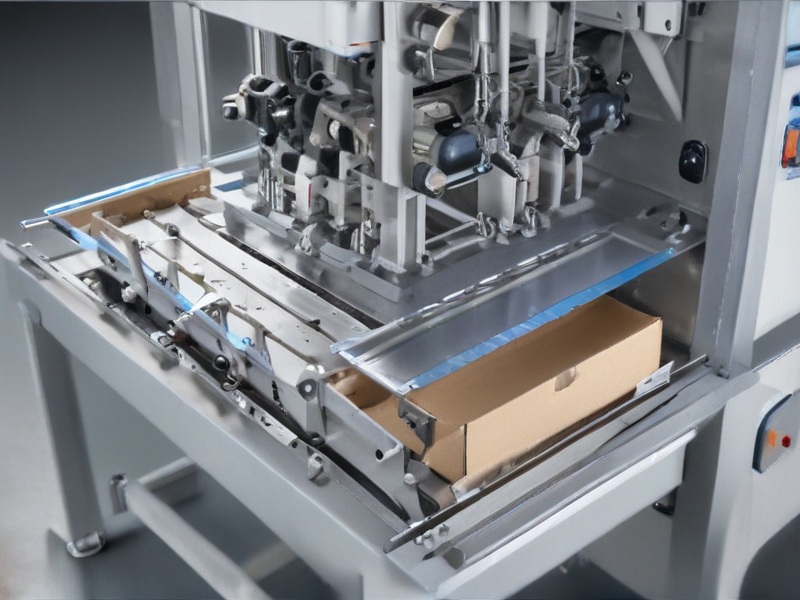

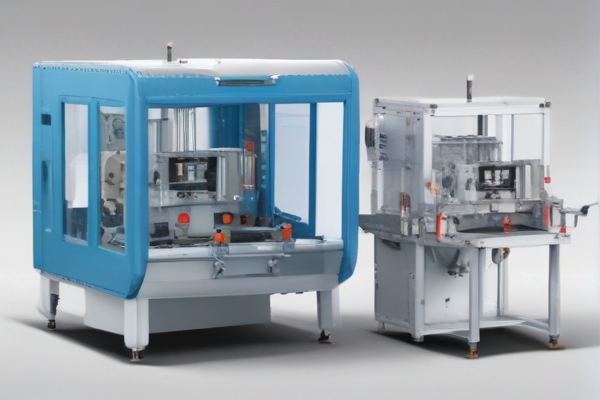

Q: What types of fastener packaging machines does SourcifyChina offer?

A: SourcifyChina offers a range of fastener packaging machines, including automatic, semi-automatic, and manual models. These machines are capable of handling different types of fasteners such as screws, bolts, and nuts.

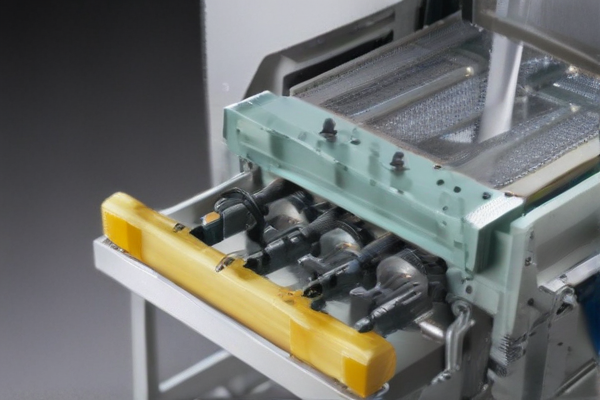

Q: Can the packaging machines handle different sizes of fasteners?

A: Yes, the machines are designed to handle various sizes and types of fasteners. They come with adjustable settings to accommodate different dimensions and quantities.

Q: What is the lead time for delivery?

A: The standard lead time is between 30 to 45 days from the date of order confirmation, depending on the specifications and customization required.

Q: Do you provide customization for the packaging machines?

A: Absolutely. SourcifyChina offers customization options to meet your specific packaging needs. You can discuss your requirements with our team to get a tailored solution.

Q: What is the warranty period for your packaging machines?

A: The standard warranty period is 12 months from the date of installation. Extended warranties are also available upon request.

Q: Do you offer installation and training services?

A: Yes, SourcifyChina provides on-site installation and training services to ensure your team can operate the machines efficiently. Remote support is also available.

Q: Are spare parts readily available?

A: Yes, we maintain a comprehensive stock of spare parts to ensure minimal downtime for your operations. Spare parts can be ordered directly from SourcifyChina.

Q: What are the payment terms?

A: Payment terms typically include a 30% deposit upon order confirmation and the remaining 70% before shipment. We accept various payment methods like T/T, L/C, and others.

Q: How can I get a quote for a fastener packaging machine?

A: You can get a quote by contacting us directly through our website, providing details about your specific requirements. Our team will respond promptly with a detailed quotation.

Q: Is after-sales support available?

A: Yes, we provide comprehensive after-sales support, including technical assistance, maintenance services, and troubleshooting help to ensure the longevity and efficiency of your packaging machine.