Sure, here’s a list of frequently asked questions (FAQ) for manufacturing fill form and seal machines by SourcifyChina:

FAQ

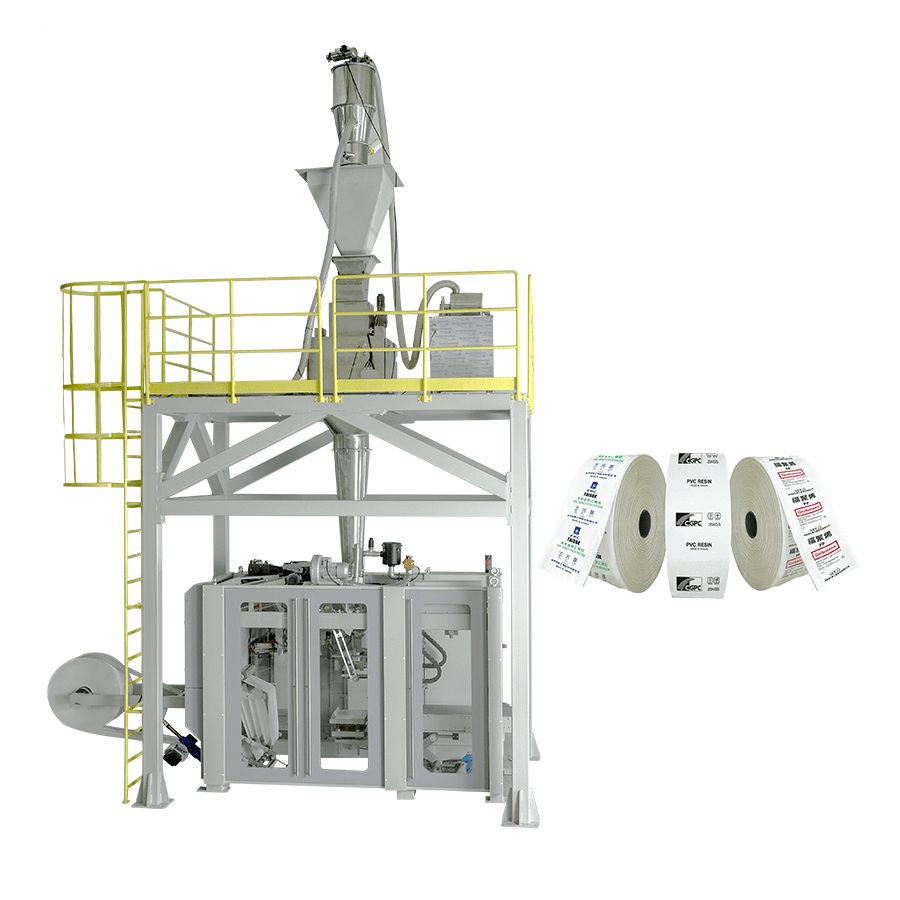

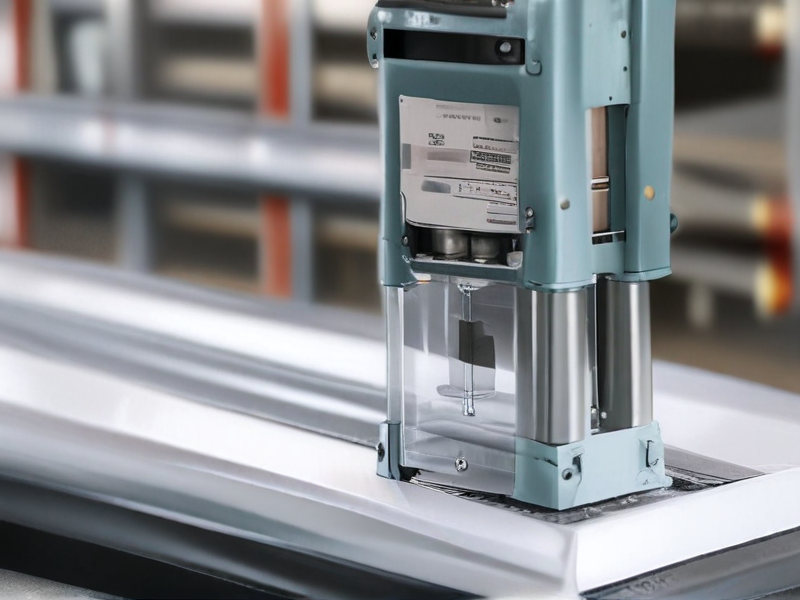

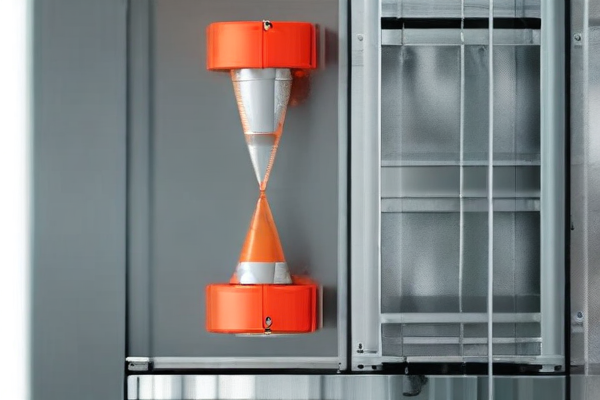

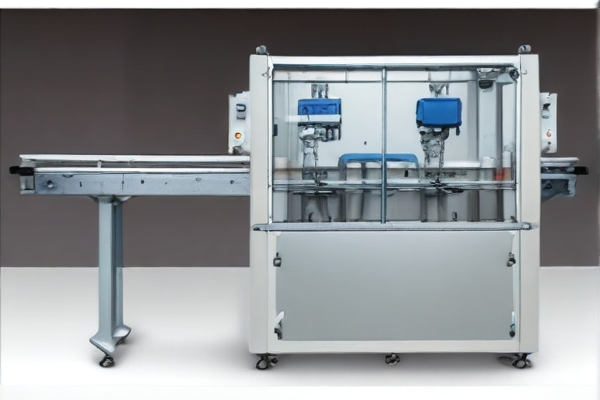

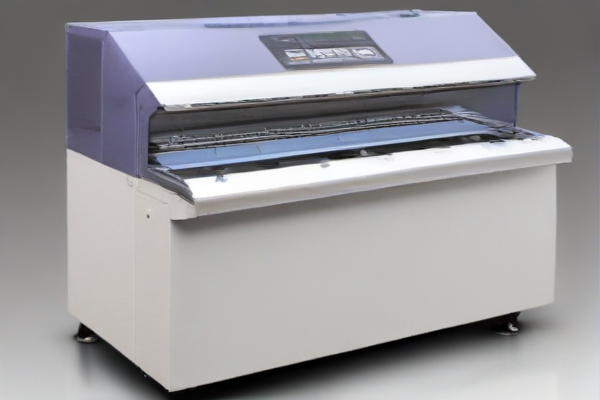

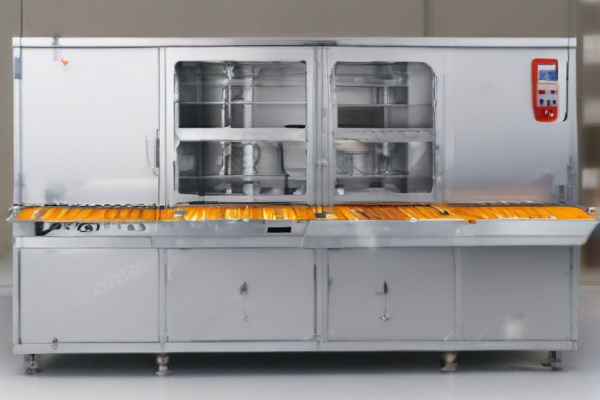

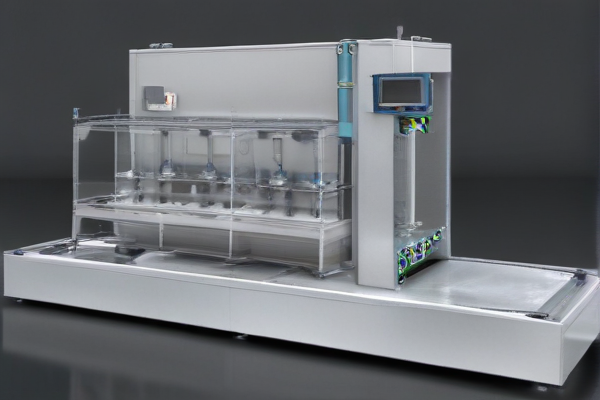

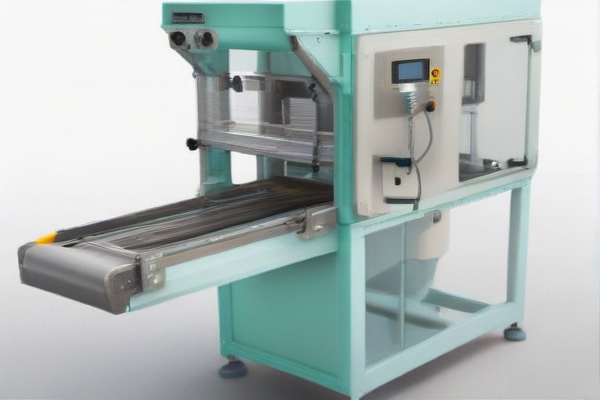

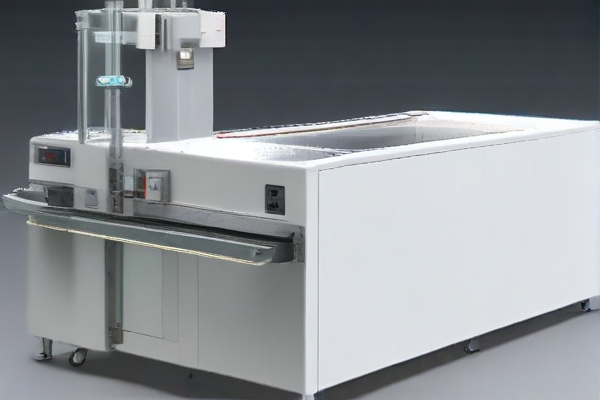

1. What is a fill form and seal machine?

A fill form and seal machine automates the packaging process by forming, filling, and sealing packages in a streamlined manner. This machine is often used for packaging food, beverages, pharmaceuticals, and other products.

2. Why should I choose SourcifyChina for manufacturing these machines?

SourcifyChina offers high-quality, reliable, and customizable fill form and seal machines. We are known for our cutting-edge technology, excellent customer service, and stringent quality control, ensuring superior performance and durability.

3. What materials can be used with these machines?

Our machines are compatible with a variety of materials, including plastic films, laminates, and other flexible packaging materials. Specific compatibility depends on the machine model and its configuration.

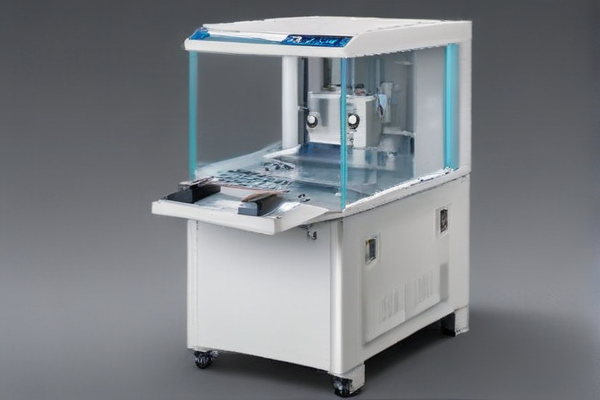

4. Are the machines customizable?

Yes, SourcifyChina provides customization options to meet specific client requirements. This includes modifications in size, functionality, material compatibility, and automation levels.

5. What is the typical production capacity?

Production capacity varies based on the model and configuration of the machine. Generally, our machines can handle anywhere from a few hundred to several thousand packages per hour.

6. What quality control measures are in place?

Our factory follows stringent quality control protocols, including regular inspections, testing, and certifications. We adhere to international quality standards to ensure the reliability and efficiency of our machines.

7. How is customer support handled?

SourcifyChina offers comprehensive customer support, including installation assistance, training, regular maintenance, and troubleshooting services. Our support team is available to address any issues promptly.

8. What are the lead times for manufacturing and delivery?

Lead times vary based on the machine specifications and order volume. Typically, it ranges from 6 to 12 weeks. Our team will provide a detailed timeline upon order confirmation.

9. Do you provide operator training?

Yes, we offer operator training to ensure your staff can efficiently and safely operate the machines. Training can be conducted on-site or via online sessions, depending on client preferences.

10. What are the payment terms?