Below is a list of Frequently Asked Questions (FAQ) along with their answers related to the manufacturing of “fill machine quality work from SourcifyChina factory”. Each question is formatted in bold as requested.

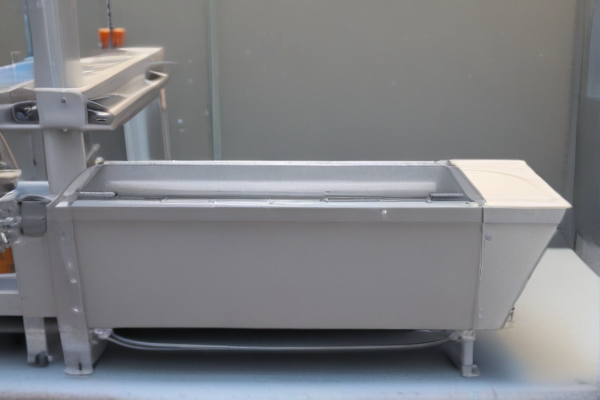

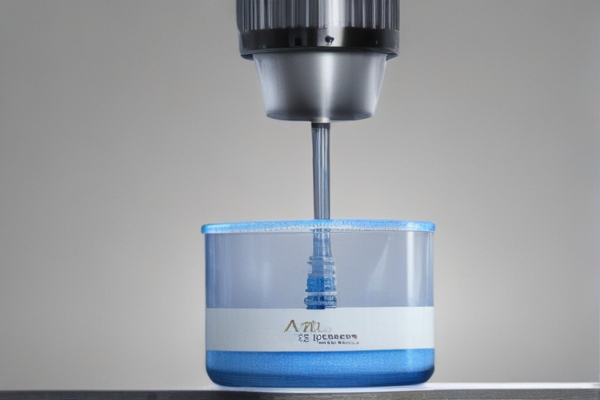

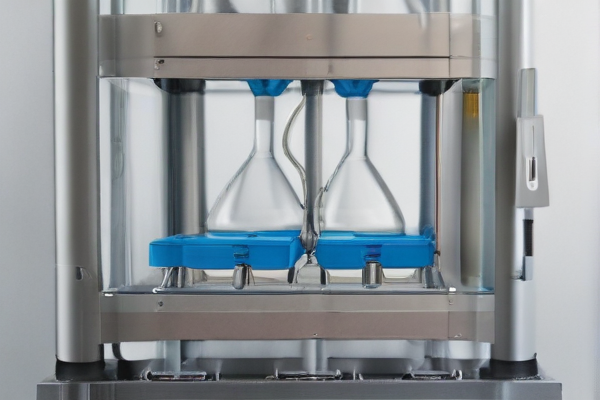

What types of fill machines does SourcifyChina factory produce?

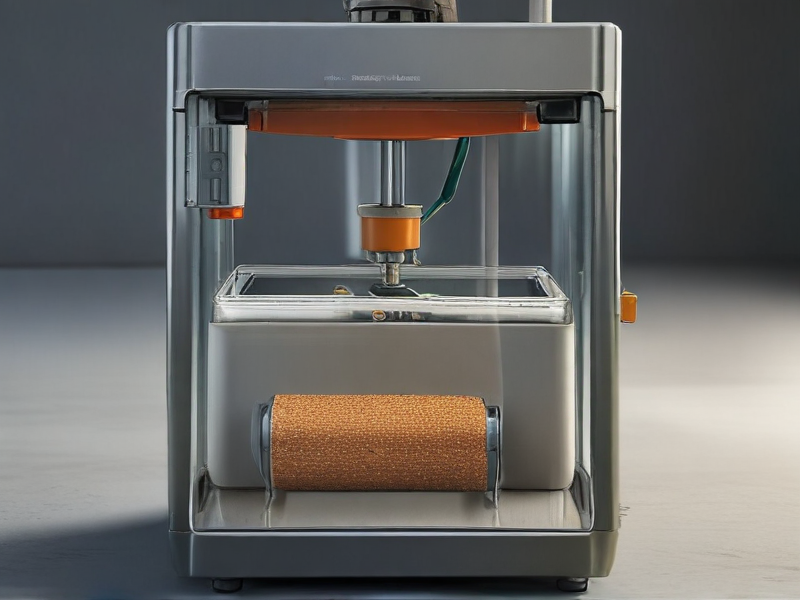

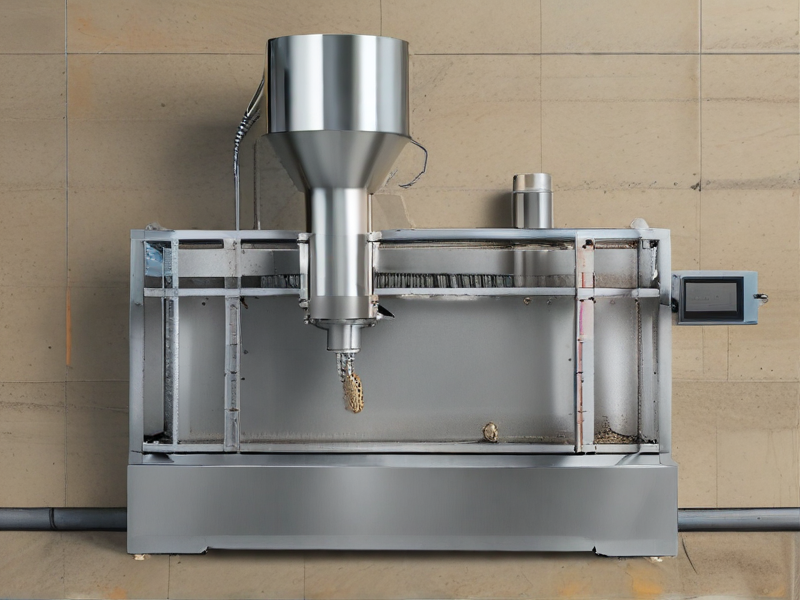

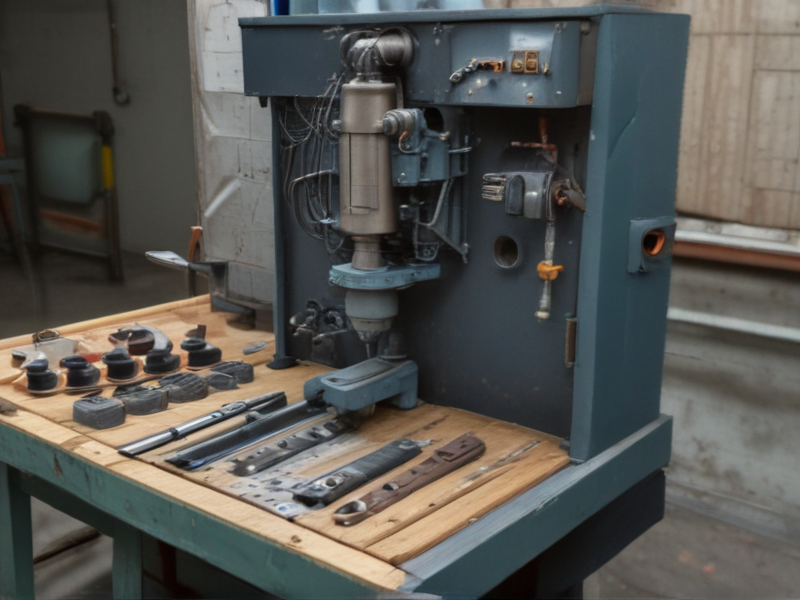

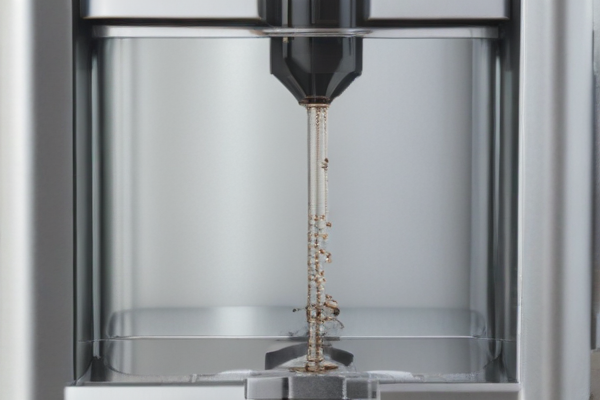

SourcifyChina factory specializes in a variety of fill machines including liquid fillers, powder fillers, and granule fillers to match different industry needs.

What is the production lead time for a fill machine?

The typical lead time for manufacturing a fill machine is around 4-6 weeks, depending on the complexity of the requirements and current production queue.

Do you offer customization for fill machines?

Yes, SourcifyChina factory provides customization options to meet specific customer requirements including size, capacity, and materials used.

What quality control measures are in place at SourcifyChina factory?

SourcifyChina factory adheres to stringent quality control protocols involving rigorous testing at each stage of production, from raw material procurement to the final assembled product.

What certifications do your fill machines meet?

Our fill machines comply with international standards such as CE, ISO, and other relevant industry-specific certifications.

Can I get a sample machine for testing before placing a bulk order?

Yes, samples can be provided for testing purposes. However, this is subject to a deposit which will be refunded upon placing a bulk order.

What kind of after-sales support do you offer?

We offer comprehensive after-sales support including installation guidance, maintenance training, and a one-year warranty on all our fill machines.

How do you handle shipping and delivery?

We partner with reliable logistics companies to offer global shipping. Delivery terms can be discussed and tailored according to customer needs.

What payment methods are accepted?

We accept various payment methods including T/T (bank transfer), L/C (Letter of Credit), Western Union, and PayPal to facilitate smooth transactions.

Is there a minimum order quantity (MOQ)?

Our minimum order quantity may vary based on the machine type and customization level, but generally, it starts with a single unit.

Remember, our sales and support teams are always ready to assist you with any additional questions you might have.